Good day everyone ! With you company

3Dtool . Today we will get some experience from our white bathrobes and share it with you. Maybe someone already practices such tricks, but maybe someone will be useful.

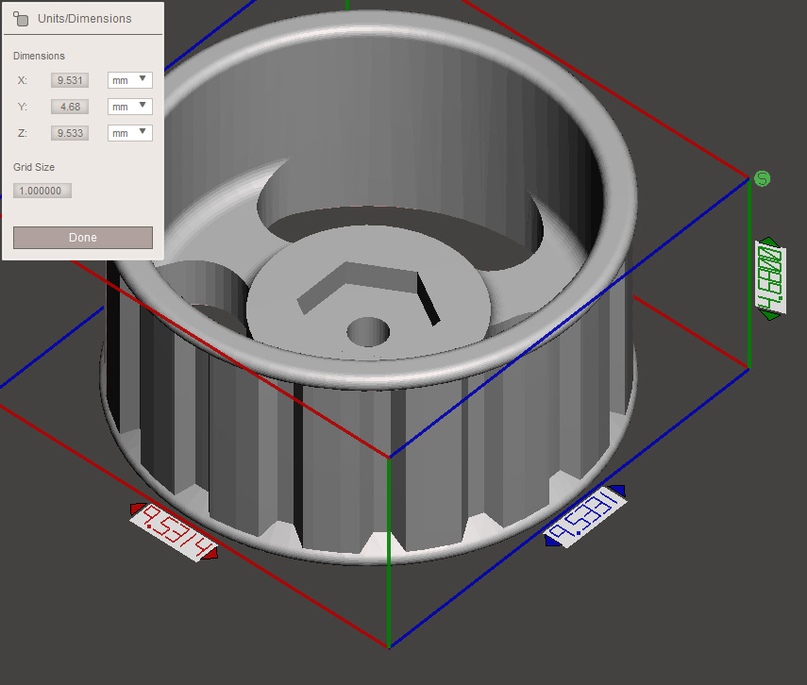

Once the task was set to print on a 3D printer

Hercules Strong 17 a car disk with a diameter of

9.5 mm , a nozzle with a diameter of

0.3 mm ,

ABS and

PLA plastic.

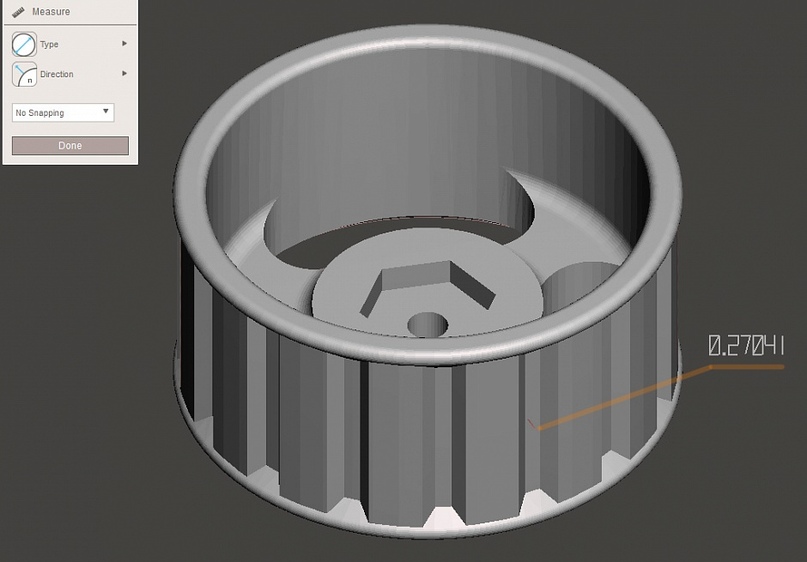

What is there to think, we quickly scaled the already existing wheel, which had seen the rains of Amsterdam, and received a very unexpected parameter. The wall thickness turned out to be

0.27041 mm , and this is slightly less than the diameter of the nozzle, which is installed on the printer, so ... "Oops."

It was decided that simply changing the nozzle to

0.2 is for wimps.

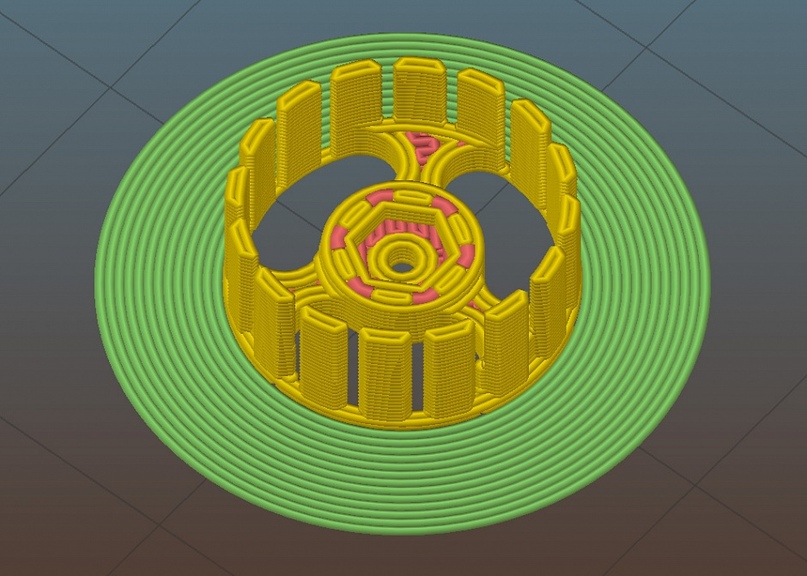

If we calculate the code at the standard settings for a nozzle with a diameter of

0.3 mm , we get the following result -

Slic3r in the focus does not notice the walls whose thickness is less than the extrusion width — holes are obtained.

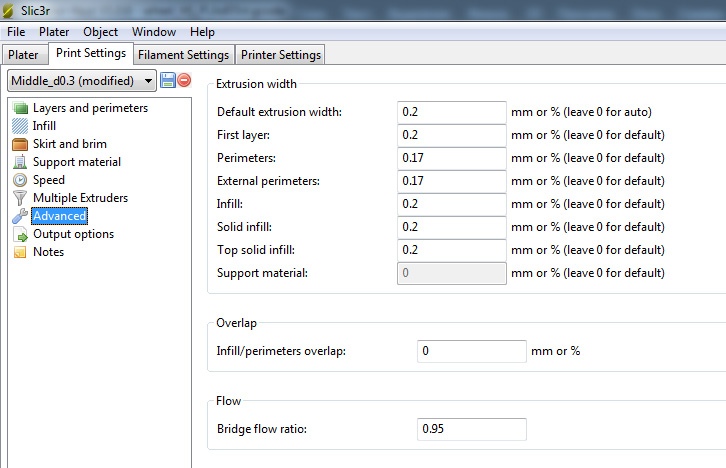

As normal specialists, the first thing that comes to mind is to change the extrusion width. Change to

0.2 mm .

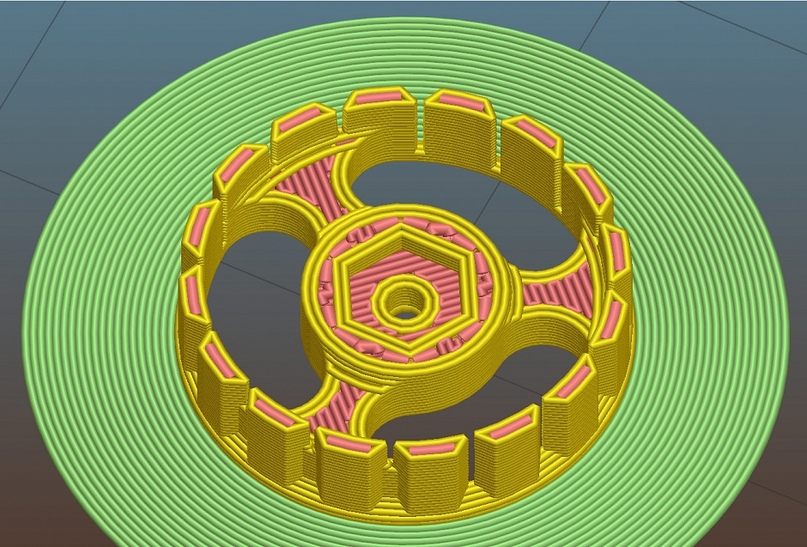

It is said yes, a pound of worthlessness, a gram of result. And then the crime begins: we change the extrusion width on the perimeters by

0.17 mm .

Slic3r

Slic3r (as a law-abiding small) laid one perimeter on both sides of the wall in those places where there were voids.

Overlap option is disabled. Activation of this parameter allows the perimeters and pouring more densely soldered between each other, due to the fact that

Slic3r adds plastic to the extrusion width value (depending on the value that is set in

overlap ). We already have everything tight on the perimeters +

50 micron layer, if you activate

overlap , you will get overflows.

Temperature

TemperatureWhile printing such little things, the extruder is always above the part. The low extrusion width does not allow to increase the speed more than

15-20 mm / s in order to avoid extrusion breakage and “cheese holes”. Therefore, it is likely to overheat the part. Nobody wants to scrape off the table illiquid. Therefore, we reduce the temperature of the extruder to

185-190 degrees (PLA BF), the blower is set at

80% power.

For

abs . Reduce the temperature to

210 degrees , turn on the airflow at

5% .

ResultIt would be naive to tell, and you believe in all the above stories, without showing the printed details. Let's look at the result.