Section 1. Relevance

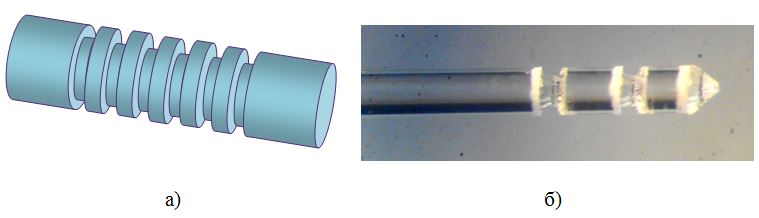

Currently, endovasal laser coagulation of varicose veins (EVLK) is a modern and effective method of treating varicose veins. The composition of medical devices for laser coagulation of varicose veins includes a fiber instrument (light guide) with a radial radiation output (Fig. 1), through which the radiation directly affects the biological tissue. The effectiveness and safety of treatment depends on the configuration and quality of processing of this instrument.

Fig.1 Possible relief of fiber: a) - model of the workpiece, b) enlarged image of the processed workpiece

Fig.1 Possible relief of fiber: a) - model of the workpiece, b) enlarged image of the processed workpieceFor laser processing, the light guide is installed in a cam cartridge of a special lathe. The installation process includes basing and consolidation. The actual position of the installed workpiece differs from the deviation required by a certain amount - the installation error:

\ begin {eqnarray}

\ triangle \ varepsilon_y & = & f (\ triangle \ varepsilon_b, \ triangle \ varepsilon_z),

\ end {eqnarray}

-

- base error, mm;

-

- fixing error, mm.

In the process of mass production, the processed light guide is installed without alignment. In the general case, the geometric axis of the fiber does not coincide with the axis of rotation of the cartridge, which leads to the beating L. in the process of rotation of the workpiece.

Experimental data on the measurement of beating when fixing various diameters of the processed optical fibers showed that its value can reach 250 μm, which does not allow processing the fiber with laser radiation with sufficient accuracy for practical use. The elimination of the beats produced by adjusting the chuck jaws is not acceptable due to the high labor intensity, time consuming and significant subjective assessment of the person - the machine operator in the sufficiency of eliminating beats. Therefore, an urgent task is posed: to develop a principle that ensures the compensation of the beating during fiber processing.

Section 2. Installation Description

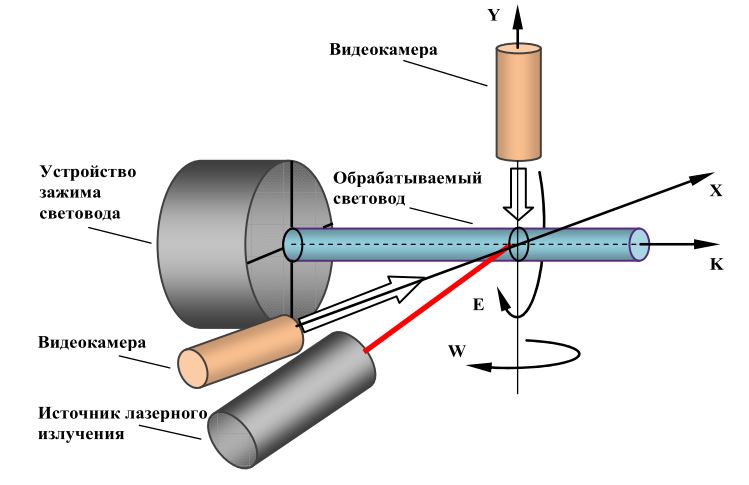

The machine for laser processing of the fiber is a motorized table that provides movement of the fiber in three longitudinal axes X, Y, K and rotation in the axes E and W (Fig.2).

Fig. 2 - An explanatory drawing of the installation diagram

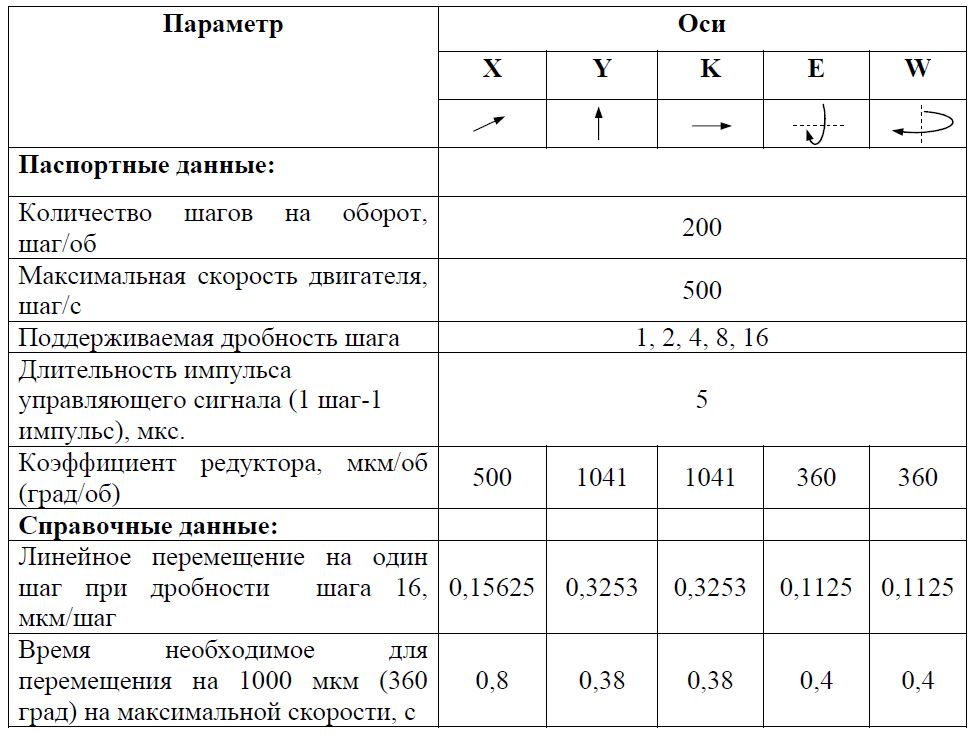

Fig. 2 - An explanatory drawing of the installation diagramMovement along the X, Y, K axes is ensured by a pair of gearmotor, along the E and W axes - by a motor. The motor is a stepper motor controlled by a local controller - driver (Toshiba TB6600HG). The driver's input signals are two TTL level signals providing the setting of the direction and speed of the stepper motor. The speed of rotation is determined by the repetition rate of rectangular pulses. The output shaft of the engine of each of the axes X, Y, K is rigidly connected with the gearbox, which provides a change in the rotational type of motion at the input to the translational one at its output. Movement along the X, Y, K axes is limited on both sides by end sensors. The position control system on each axis is open. Technical parameters of axle drives are presented in Table. one.

Tab. 1 - Technical parameters of axle drives

The processing object is a fiber with a diameter of 330 μm, which is fixed in a clamping device - a cartridge (Fig. 2). The cartridge provides mounting and rotation of the light guide.

The processing tool is a CO2 laser with a wavelength of 11 microns.

Section 3. Beat Compensation

3.1 Problem Statement

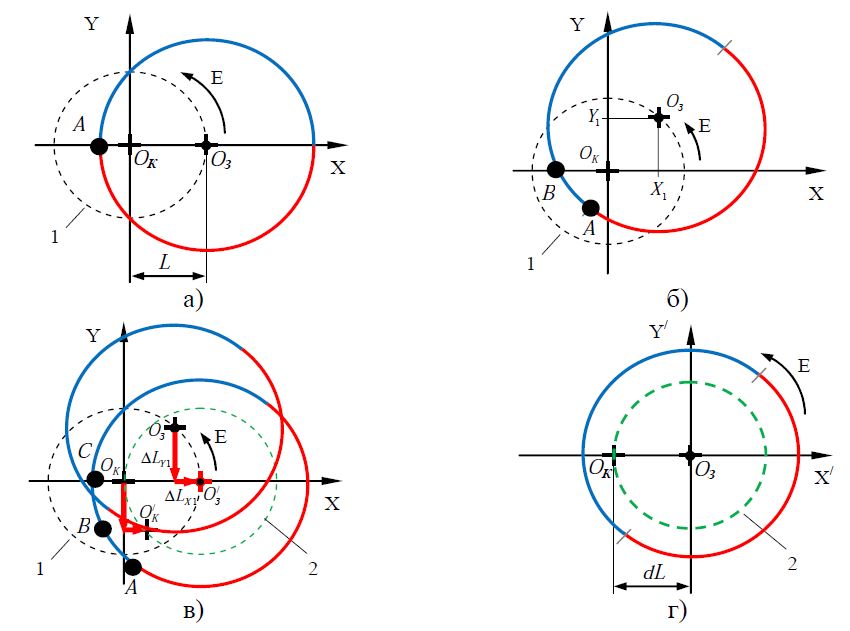

When clamping the workpiece - the light guide in the chuck of the machine its center

gets offset - L relative to the center of the cartridge - point

(coordinate system center). This offset has a different meaning for each fixing of the fiber. When rotating fig.4a center of the fiber

describes a circle of radius L - beating value. The goal is to reduce the amount of beating.

Fig. 4 - The relative position of the axis of the cartridge and the fixed fiber during rotation: a) the amount of beats when the sample is fixed in the cartridge of the machine; b) turning the cartridge 45 degrees in one step of the engine; c) the introduction of corrective amendments to the position of the axis of the cartridge; d) the movement of the axis of the cartridge relative to the fixed axis of the light guide with compensation for each step of the engine.

Fig. 4 - The relative position of the axis of the cartridge and the fixed fiber during rotation: a) the amount of beats when the sample is fixed in the cartridge of the machine; b) turning the cartridge 45 degrees in one step of the engine; c) the introduction of corrective amendments to the position of the axis of the cartridge; d) the movement of the axis of the cartridge relative to the fixed axis of the light guide with compensation for each step of the engine.3.2 Principle of the proposed solution

Consider the movement of the fiber in the plane

when it rotates about the axis of the cartridge - point

.

Let at the initial moment of time the axis of the workpiece is a point

is located on the X axis and has coordinates (L, 0) and the laser beam hits the surface of the fiber at point A (Fig. 4a).

For clarity, rotate the cartridge at an angle

in one step of the engine (Fig.4b). Wherein:

- point

gets coordinates

;

- the projections of the magnitude of the beating L on the X-axis and Y will take values

,

;

- the laser beam will move along the fiber surface to point B.

When the optical fiber is rotated, we will need to return the coordinates of the point

to its original position with the coordinates (L, 0). For this, it is necessary to introduce corrective corrections to the position of the cartridge point along the X and Y axes of Fig. 4c on the size of the projections

,

. These corrective corrections are carried out at the expense of the stepping motors of the axes X, Y. In this case, the point

again, the initial coordinates will be (L, 0), and the laser beam will hit the point C of the fiber surface.

During the subsequent rotation, new corrective movements of the cartridge axis will be required. With this point

the axis of the cartridge will move around circle 2 (Fig. 4d). The magnitude of the radius of the circle 2 is equal to the magnitude of the beating L. With this solution of the problem, the fiber axis is in relative immobility about its axis, and the axis of the cartridge moves in a circle, therefore we will consider the fiber rotation in the plane

regarding point

by moving the coordinate system for this (Fig. 4d).

3.3 Mathematical justification of the proposed solution

The considered principle of beat compensation presupposes the presence of known values of corrective movements.

,

(beat increments) of the cartridge at each (i + 1) step of the stepper motor during the rotation of the light guide. To determine them, consider fig.5.

Fig. 5 - The magnitudes of the projections when the fiber is rotated relative to the cartridge axis counterclockwise (positive direction)

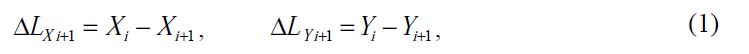

Fig. 5 - The magnitudes of the projections when the fiber is rotated relative to the cartridge axis counterclockwise (positive direction)At each next step of the stepper motor, the rotation axis E will receive increments due to the beating L:

where are the coordinates

determined from the displacement geometry (Fig. 5):

Graphic view of the change increments

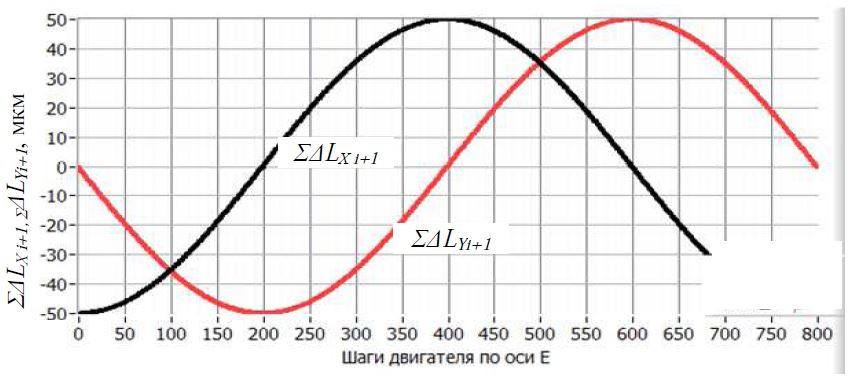

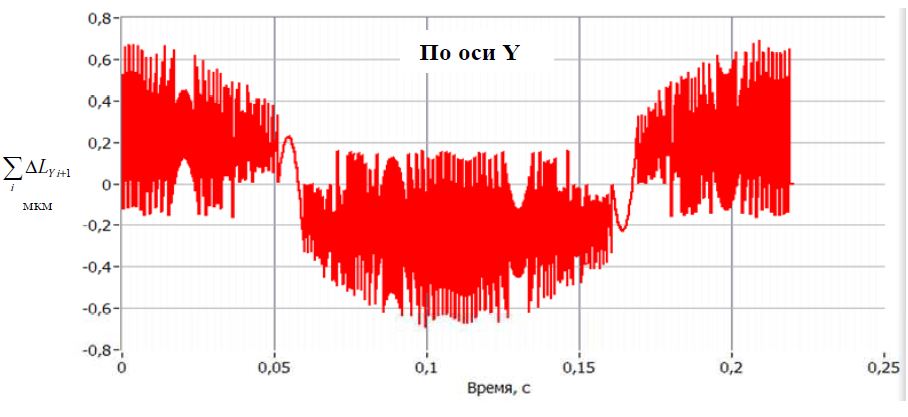

for each i step when rotated counterclockwise (fractional increment in E = 4) with a beating of 50 μm is shown in Fig.6.

Fig. 6 - Changes in the magnitudes of the projections (displacements) at each step of the motor along the X and Y axes caused by a beating when the fiber rotates 360 degrees counterclockwise (fraction of a step by E = 4) with a beating of 50 μm.

Fig. 6 - Changes in the magnitudes of the projections (displacements) at each step of the motor along the X and Y axes caused by a beating when the fiber rotates 360 degrees counterclockwise (fraction of a step by E = 4) with a beating of 50 μm.In the absence of compensation, the numerical integration with the corresponding initial conditions for the expressions

will give the current projection on the axis of Fig.7

Fig. 7 - The current projections of the displacements at each step of the motor along the X and Y axes due to the beating when the fiber is rotated 360 degrees counterclockwise (fraction of the step by E = 4) with the beating L = 50 μm.

Fig. 7 - The current projections of the displacements at each step of the motor along the X and Y axes due to the beating when the fiber is rotated 360 degrees counterclockwise (fraction of the step by E = 4) with the beating L = 50 μm.In the process of rotation, with the accumulation of the magnitude of the beating is greater than the magnitude of the control action, its compensation must pass. This reflects the following condition:

Where

- linear displacement along the X axis in one motor step:

- the magnitude of the linear displacement along the Y axis in one motor step.

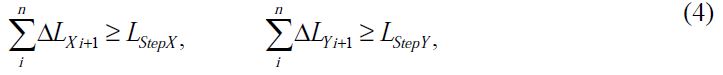

Condition (4) can be modified to obtain a smaller error in the beat compensation.

In the presence of compensating pulses, the total displacement

,

decrease - fig.

Fig. 8

Fig. 8 - Change of size of shifts

along the X axis in the process of rotation along the E axis with beating compensation. Beating L = 50 µm, initial angle

= 0

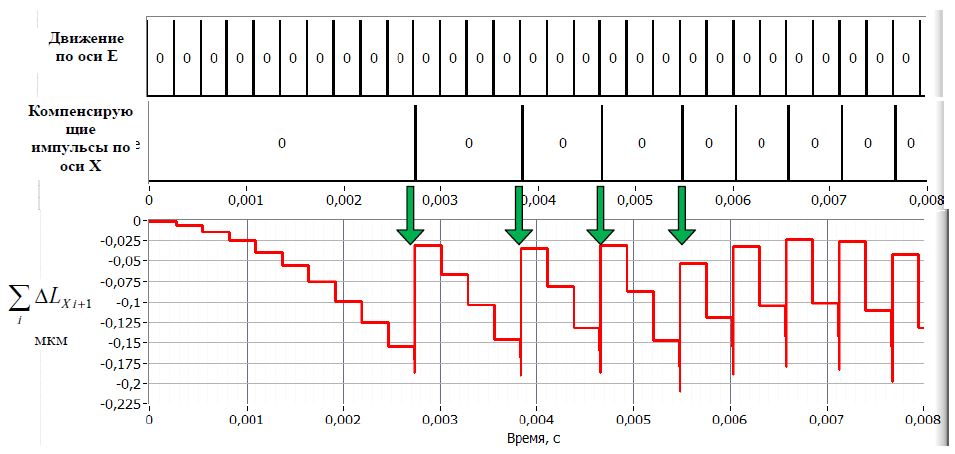

3.4 Performance Evaluation

The overall picture of the beating compensation process is L = 50 µm when turning on

with the proposed principle is presented in Fig. 9.

a)

b)

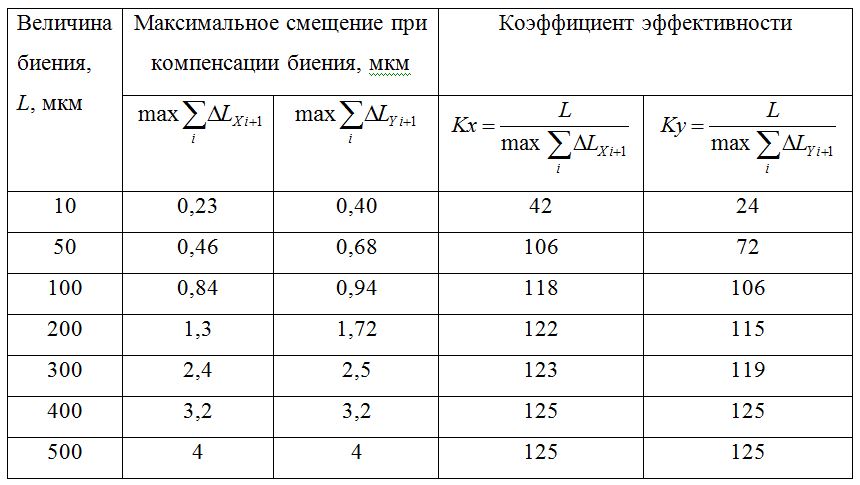

Fig. 9 - The magnitude of the displacements along the axes when compensation of the beating is L = 50 μm per one revolution of the fiber: a) for the X axis, b) for the Y axisIt is proposed to evaluate the efficiency of beating compensation by a ratio equal to the ratio of the maximum displacement along the axis in the compensation process to the beating value of the table.2.

Tab. 2 - Beat compensation efficiency

Estimated maximum displacement

,

for the presented values of the beats and the practical operation of the installation with the proposed principle of the compensation of the beats, it was shown that it is possible to apply a relief to the light guide using laser radiation with sufficient accuracy for practical application.

It should be noted that when processing a fiber with laser radiation with beat compensation, the time of one revolution of the fiber relative to its axis will depend on the beat value and change for each treatment. For example, with a beating of 50 microns, the time of one full turn:

- without beat compensation: 400 ms;

- with beat compensation: 560 ms.

This fact must be taken into account when adjusting the laser power.

Section 4. Determination of the beat

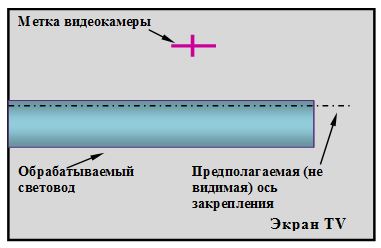

To implement the presented principle of beating compensation, it is required to know its size - L. It is proposed to determine the beating value by a video surveillance system (video camera 1 in fig. 1). In fig. 10. schematically shows a video form from a video camera.

Fig. 10 - Arbitrary arrangement of the fixed fiber on the monitor screen

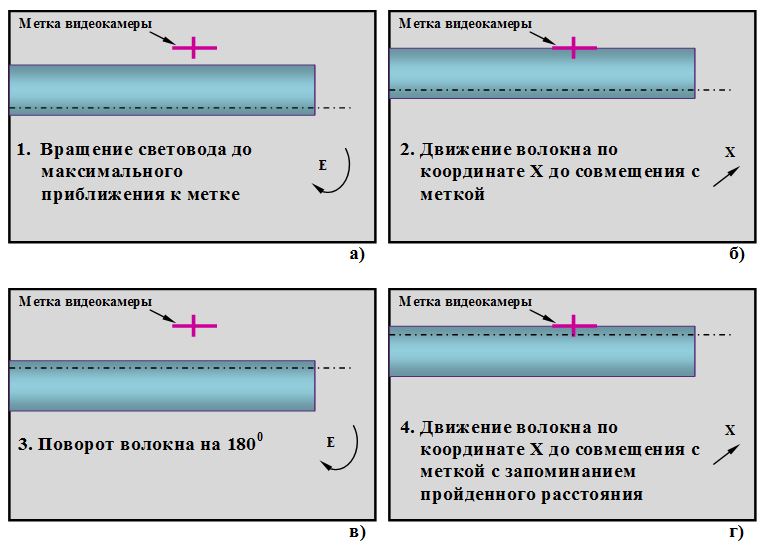

Fig. 10 - Arbitrary arrangement of the fixed fiber on the monitor screenTo determine the amount of beats, you must perform the following steps in the order indicated:

- to rotate the light guide (E axis) up to the maximum approximation to the mark on the screen (Fig. 11a);

- move the fiber along the coordinates of the X axis to align it with the label (Fig. 11b);

- turn the fiber on (Fig. 11c);

- to move the fiber along the coordinates of the X axis until it coincides with the mark, remembering the distance traveled R (counting the number of motion impulses of a stepper motor) fig. 11g;

- calculate the value of the beating L = R / 2.

Fig. 11 - Stages of determining the value of the fiber beating

Fig. 11 - Stages of determining the value of the fiber beatingSection 5. Conclusion

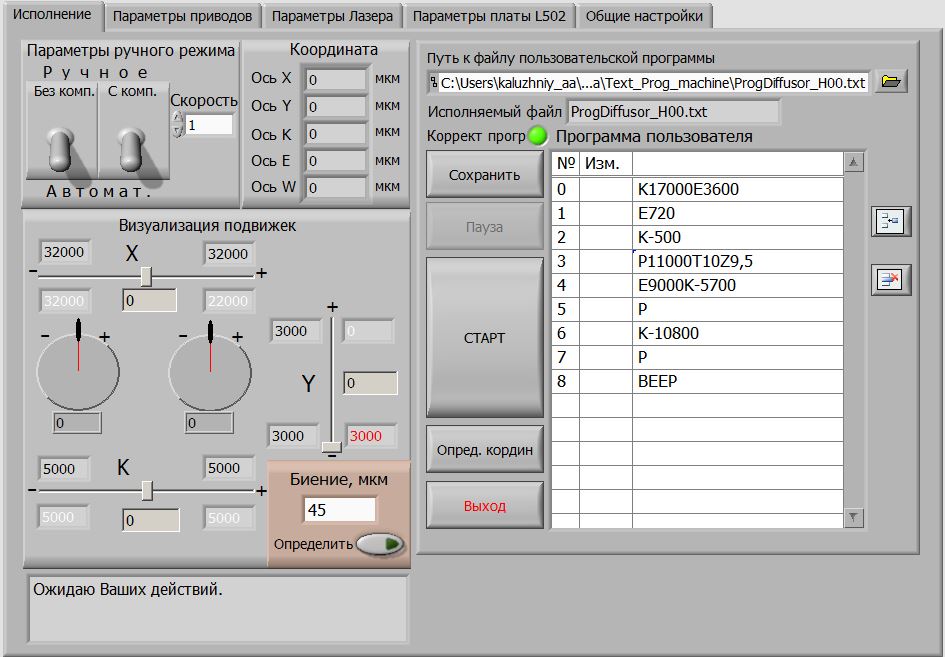

The proposed principle of beating compensation is implemented on the National Instruments LabVIEW software platform, has been tested, implemented, and showed the effectiveness of its work (Fig. 12).

Fig. 12 - The front panel of the program

Fig. 12 - The front panel of the program