When the ASCON technical support receives requests, each of them is assigned an individual SD number # XXXXX. Under this code, user suggestions are discussed and error messages are processed. What kind of dramas does the SD # code hide and how are the most difficult cases resolved - in the query history of the Sverdlovsk instrumental plant, which ASCON technical support engineers, the developers of the COMPASS-3D system and C3D Labs worked on together.

Mold under threat!

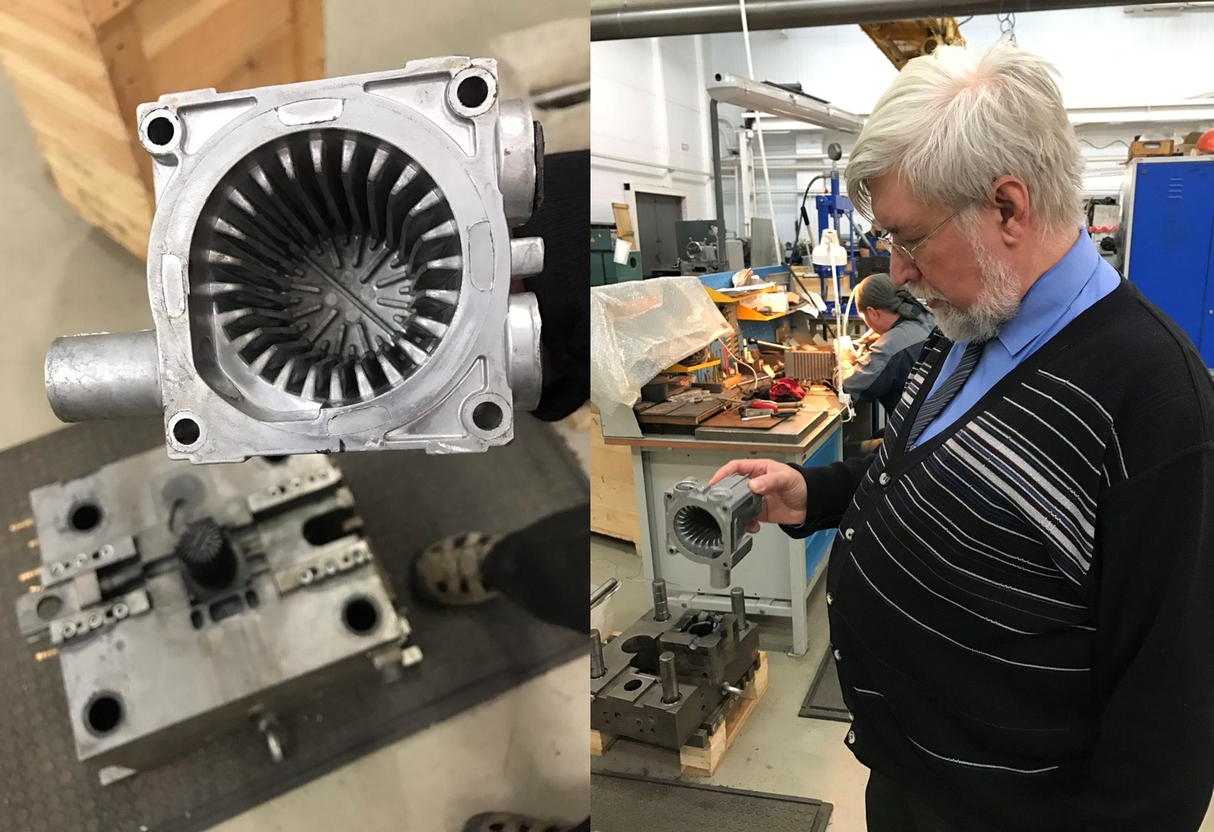

Alexey Pavlovich Grekov, Lead Designer of Sverdlovsk Tool Plant, JSC, has been designing molds for 36 years and the last 15 of them have been working in the KOMPAS-3D design system. He approaches his work very thoroughly and responsibly, tracking the fate of his products until they are made. Therefore, Alexei Pavlovich can often be found in the production shops of the plant.

In addition to its own products, the plant manufactures molds for third-party organizations. One of such orders was the cause of a request to ASCON technical support under the SD number # 7109384.

The model that was to be handed over to the customer in an exchangeable format (stp, x_t, sat), after going through the export-import procedures, was created as a surface, and not as a solid. This meant that the customer would not be able to work with it in the future.

The problem coincided with the transition of KB staff to KOMPAS-3D v17, which, of course, caused suspicions about the new version: “Not only did they change the interface, they also broke export!”.

Alexey Pavlovich Grekov, Lead Designer, Sverdlovsk Tool Plant, JSC:

Our customer does not have KOMPAS-3D. He needed the model not only for viewing (KOMPAS Viewer would be suitable for this), but also for further processing and assembly. Therefore, it was required to conduct export-import correctly and obtain a solid-state model, not a surface one. In the previous version of KOMPAS (we had version 15.2), the translator to transitional formats worked much better, and such errors were very rare.

Dialogue with technical support

Alexey Pavlovich: I need the model to be read by a solid body. And urgently, because terms of coordination with the customer have already passed.

Technical support: Unfortunately, in this case, the import is abnormal, it is an error in COMPASS.

Alexey Pavlovich: And what should I do ???????

Technical support: The developers have recognized the error, it will be fixed later.

Alexey Pavlovich: Very bad. Over the past 5-6 years, I don’t remember that the compass let me down so steeply. : - (((I was hoping for him.

An export error was fixed and waited for its turn to correct. But the customer of the mold was not going to wait, and Alexey Pavlovich again turned to ASCON technical support.

Alexey Pavlovich: The described problem is encountered more and more often, on various details. And the need to transfer projects in transitional formats increases as new projects are developed. Please speed up the elimination of the indicated error.

Vladimir Lipin, head of the ASCON Technical Support Service, joined the request. He drew the attention of developers that the problem has become critical for the user.

Having studied the situation, the developers found out - it's in mathematics. Externally, the mold model looked closed, and KOMPAS-3D completed it as closed. In fact, the ribs did not converge, so the model was broken and became superficial. The task was highly specialized, standard mathematics of the geometric core C3D, on which KOMPAS-3D is based, did not cheat it.

The developers have proposed a workaround: change the geometry, correct the edges so that the model closes. But it turned out that it is impossible to change the geometry, since Accuracy is very important. The workaround did not pass.

Vladimir Lipin, Head of ASCON Technical Support Service:

The situation was emotional: you do not want to correct the mistake and suggest that we move the ribs. Users had the impression that everything was fine in the old version, and in the 17th version, the programmers did something that the model ceased to be exported.

Life is such that while the designers of the plant switched from version 15 to 17, they significantly improved their model. And the point was not that some functionality in the COMPASS stopped working. The model became more complicated: such rounding, bending, and edge combinations that mathematics did not allow to process were used.

Mathematicians from the C3D Labs division, which deals with the geometric core, were already aware of the problem; they needed time to figure it out.

Mold Formula

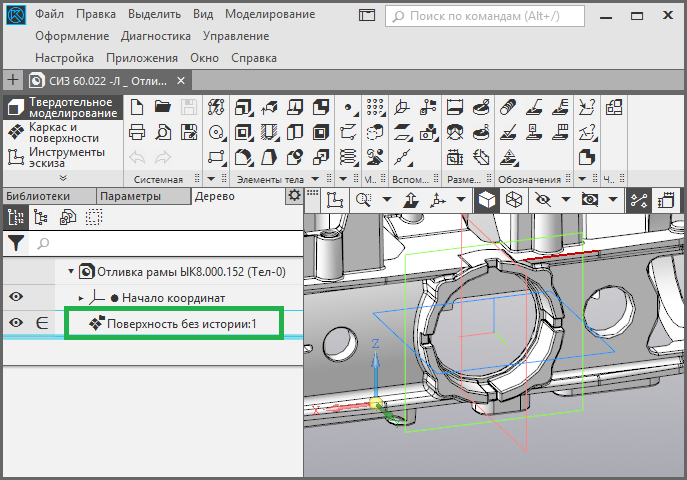

Detailed diagnostics showed that the constructed model contained defects that did not prevent its editing, but were unacceptable from the point of view of data exchange.

The fact that the closed shell after transfer through the exchange formats became open was due to the presence of edge edges in the model. They appeared as a result of a boolean operation: a contour was formed on the verge, extruded and glued to the “main” body. The contour was a little beyond the size of the face: this was due to the peculiarities of the imposed system of restrictions.

Screenshot model of the mold. The green arrow shows the problem area.

Alexander Spivakov, a mathematician and programmer at C3D Labs:

The fact that the contour appears is not in itself a mistake. The problem arose due to the fact that the contour spoke out for the dimension of the facet quite a bit: the characteristic size of the protruding part was comparable to the magnitude of the error. As a result, the algorithm for Boolean operation followed the branch where the face should not have been created. Small dimensions themselves are a source of computational problems to a lesser extent than gaps of about the same size. This is true for body editing tasks, but as it turned out, not for the model export task. In this case, the problem was resolved through the refinement of the criterion according to which a decision is made to create or skip a face.

This is the mathematical solution of the export problem in the geometric core C3D.

This is the mathematical solution of the export problem in the geometric core C3D.Another source of edge edges was the rounding operation. The source data for the rounding operation includes the rounding radius and a chain of edges, which should be replaced with faces. Often the rounding operation is not local: it affects not only those faces that are adjacent to the edges of the rounded chain, but also others. Difficult situations may arise with the extreme edges of an open chain, since in order to construct a rounding correctly, it is necessary to modify the faces of all the edges that are adjacent to the extreme vertices.

If the rounding radius is larger than the size of the face in the “transverse” (with respect to the edge) direction, you must also modify the faces that are not directly adjacent to the edges on which the fillet is based. Some cases of this kind were processed using the functional intended to modify the faces adjacent to the extreme vertices. Other cases were processed separately, and as a result of the work on request SD # 7109384 correctly processed cases became more.

Morning in the core - in the evening in KOMPAS-3D

The solution found by mathematicians was immediately included in the new assembly of the geometric core C3D and in the express update KOMPAS-3D v17, which was received by the designers of the Sverdlovsk tool factory. It remained to apply the “Rebuild” command, perform export to the exchange format and check the result by reverse import.

Alexey Pavlovich: Hello. Downloaded. Installed. For the purity of the experiment, I took the detail with which this request began, in order to eliminate the influence of possible edits that were made after creating the query.

Saved as: x_t; x_b; stp AP214.

Imported a model from each listed format. Got the same result, i.e. All three new models have turned out in the form of SURFACES.

Hence the question: What did you fix there?

Tech support: Good afternoon, Alexey Pavlovich! To solve the problem, you must first rebuild the model in KOMPAS, then export. After that, the import will be the body.

Alexey Pavlovich: URAAAAA !!! Thanks, it turned out. THANK YOU, thank you, and thanks again. As far as possible we will try on other problematic details.

After some time, Alexey Pavlovich again turned to ASCON:

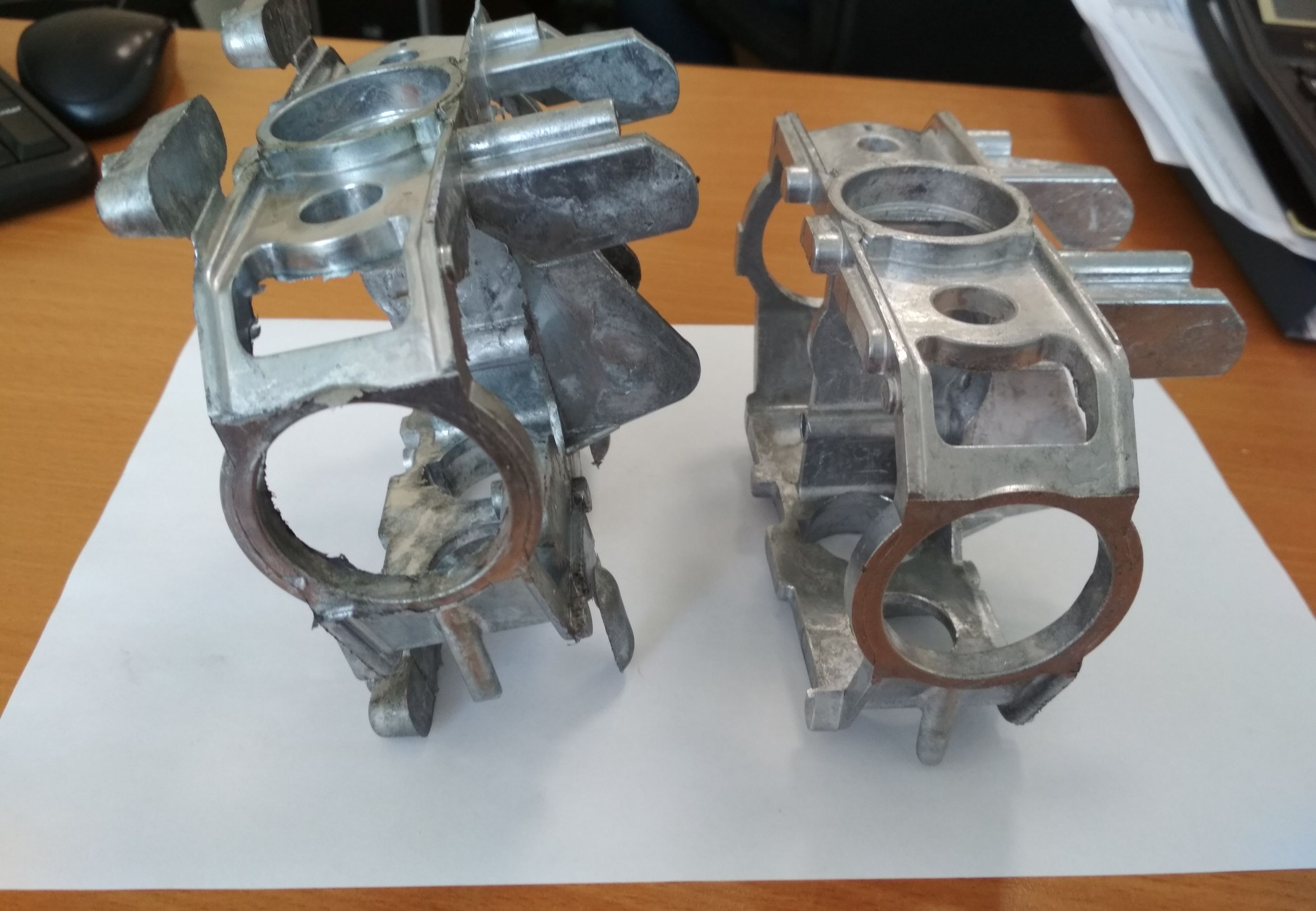

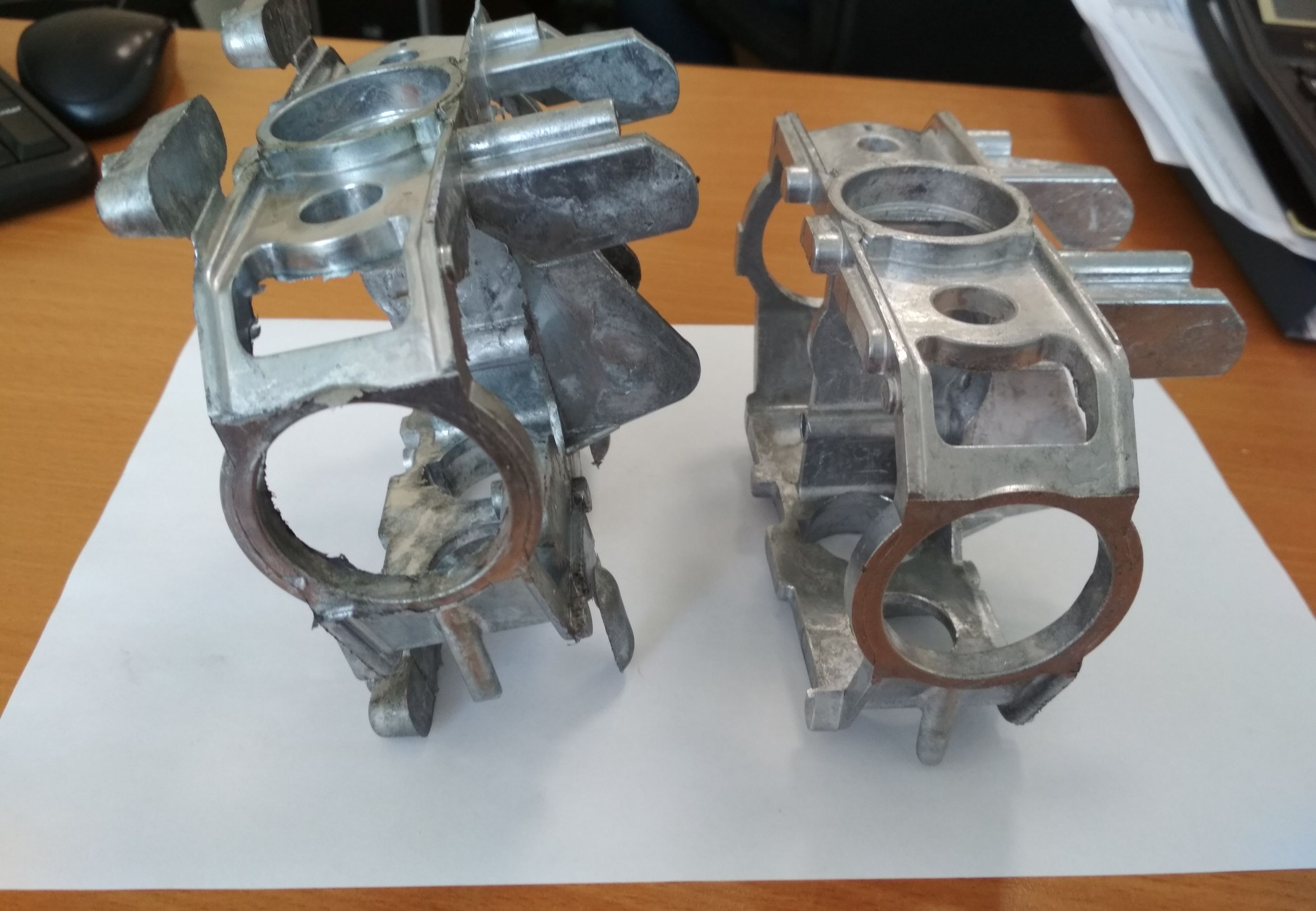

The project, during the work with which a whole chain of requests has arisen, has been successfully completed. Our company manufactured the most complicated mold for casting, with which model both we and you worked for so long. Today passed the tests made by the equipment tooling. The results are positive. All these works were carried out for a reason. Many thanks to all your team. Attached photos of what happened in the end.

Products made using the moldInstead of conclusion

Products made using the moldInstead of conclusion

Vladimir Lipin, Head of ASCON Technical Support Service:

The situation with the mold is very indicative in terms of user interaction, technical support and developers. Yes, we have a standard procedure, when confirmed errors are entered into the database and then gradually corrected. But each request is individual. We work with people, and a technical support specialist needs to be as attentive as possible, to clarify once again whether the proposed solution is suitable or not. The same regulation provides for the mobilization of additional resources in difficult situations.

Personal email-address Vladimir Lipin lipin@ascon.ru (in violation of all the rules of information security) is posted on the ASCON website so that each user can directly contact with their own question.

PS On behalf of the companies C3D Labs and ASCON, we congratulate Alexey Pavlovich on the birth of his fifth grandson!