Good day!

With you company

3Dtool .

Today we will not talk about any 3D printer model, and not about the process of 3D printing. We would like to talk about how to make the process of preparing a model for 3D printing more efficient.

We all know that a large working field is good. But what to do when we start trying to create control programs for a huge part and the program goes into perpetual waiting at the stage of cutting the layers or exporting the code to a file. There were cases when the program was prepared more than a day. To understand what is happening, you need to understand a little about the algorithm of the process that occurs inside the “Black box” of the slicer. It is not much, because it is enough to know that the most difficult and costly business, in the process of preparing the program, is dissecting the model into layers and forming trajectories along these sections.

All complexity in quality.

All complexity in quality.

As a model.

As a printed part.

In optimal quality.

In the desired quality.Sometimes it is a very loose concept ... and so on. But we have not a moment of philosophy.

Let us turn to the specifics. An example from life.

As a result of 3D scanning, inaccurate, illegal and uneconomical modeling, various transformations and conversions, there are cases when the grid of the model becomes proportionally dense, with a large number of extra polygons. This significantly increases the “weight” of the

stl file. The document begins to take up a lot of memory and increases the time it takes to form the control program code, causes the slicer to hang and go to the bottom of the operating system's process list. In such cases, the model should be optimized, i.e., the grid density should be reduced without loss of geometry quality and part quality.

Ammunition

Software for the preparation of the control program - difficult, complicated, inconvenient, but in our opinion, terribly effective,

Slic3r .

Optimization software - absolutely free, open source

Blender , supported by almost all operating systems (

https: // www.blender.org/download/ )

To business

Install and run

Blender . To import a model, go to

File -> Import -> stl , select the required model.

To optimize the model, we will use the

Decimate modifier. This modifier allows you to reduce the number of polygons in the model grid with minimal changes in geometry.

Switch to

Object mode (1), in the

Editing panel (2) select the

Modifiers tab (3), add

Add Modifier ->

Decimate (4)

Options

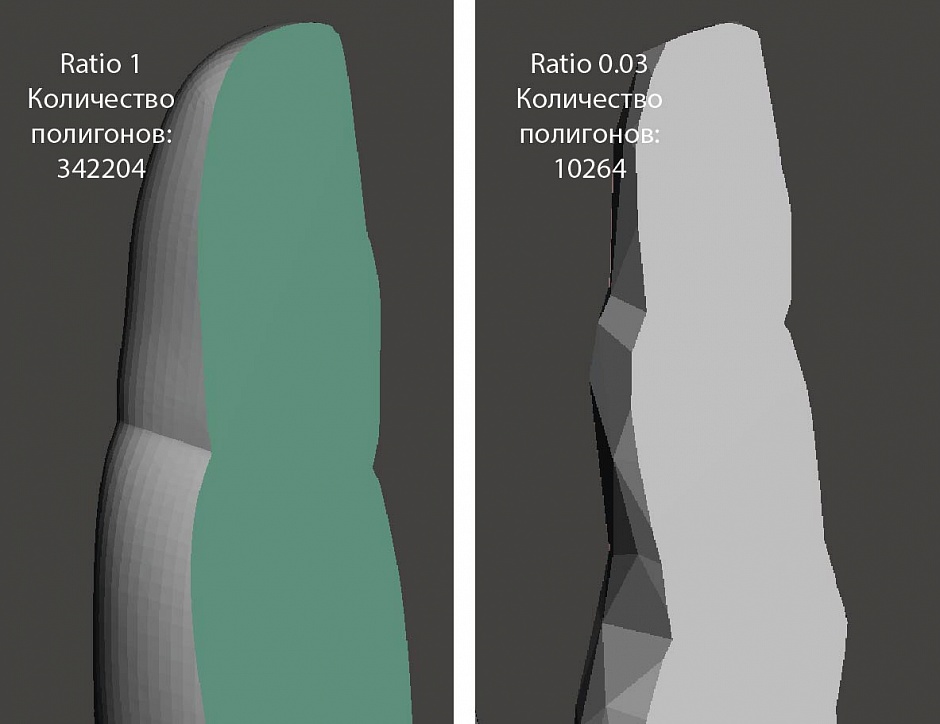

Ratio Ratio from

0.0 to

1.0 . The ratio of the details before and after optimization. 0.0 (0%) - all faces removed. 1.0 (100%) - all faces remained unchanged. As the ratio changes from 1 to 0, the number of polygons in the grid decreases.

Quality

In order to assess the level of detail to which the model will be simplified without loss of quality (visually the printed part corresponds to the mathematical 3D - model). If you really go into details, you must consider the ratio of the physical size of the printed model, the diameter of the nozzle and the height of the layer. Below, quantitatively, it shows what the result of such optimization procedures.

How not to do

Now let's go on the other side. Too low a coefficient reduces the quality of detail:

Ratio 0.05 - 0.03 . For a small model (20–30 mm), a Ratio 0.05–0.03 is appropriate, since the layer height and nozzle diameter will not physically allow you to print the necessary detail, which is maintained at higher coefficients. And we all remember that the diameter of the nozzle is

0.3mm , and the output plastic thread is a little more. This means that all sharp edges will have a radius of at least

0.15 mm .

And in the final few pictures of what can lead to excessive enthusiasm cherished parameter

Ratio .

Ratio:

Ratio: 0.015. Coefficient too low

In general, you understand.

Hopes and hopes.

We sincerely believe that this material will be useful to you, you will begin / continue to effectively use the capabilities of your 3D printer.

Efficient 3D printers for business and production Hercules (always available in our company 3Dtool) -

3dtool.ru/category/3d-printery/filter/topmanufactorer-is-imprintaherculesVideo review of the 3D printer Hercules Strong 17

on our Youtube channel .