We installed the

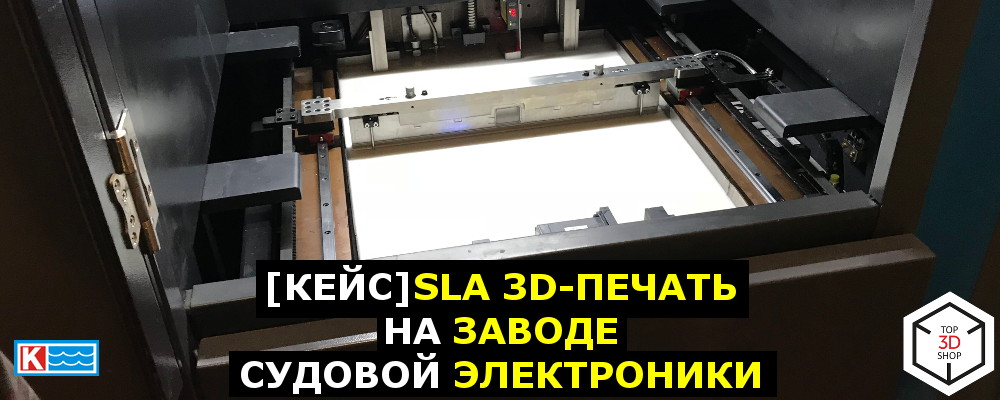

iSLA-450 Pro 3D printer at the

“A. Kulakov Plant” , which specializes in the production of low-voltage equipment and information automation, control and protection systems for ships and vessels of different classes.

Production of the plant provides safe and efficient navigation of all types of ships on all the seas of the planet.

- Laser spot diameter: 0.1-0.15 mm

- UV wavelength: 355 nm

- Material: photopolymer resin

- Printing area: 450x450x400 mm

- Power supply: 220V 50Hz

- Supported operating systems: window XP, window 7

- Power Consumption: 2000 W

- Dimensions (mm): 1100x1400x1800

- Printing technology: SLA

- Layer thickness from: 50 microns

- Printing accuracy: ± 0.05 mm (up to 100 mm), ± 0.1% (more than 100 mm)

- File Format: .STL, .SLC

- Print speed: 10 g / h

How it was done without 3D printing

Prior to the advent of 3D printing, the design and manufacture of cases and load-bearing components of the equipment was carried out using traditional methods, which included a long process of manual prototyping and testing. Digital Production Technologies provide an opportunity to significantly reduce the required time and labor costs, and thus to speed up and reduce the cost of production.

How to choose equipment

The customer - Joint-stock company “Plant named after A. Kulakov”, is engaged in the development of equipment and control systems for ships. Products manufactured by the factory are designed to equip ships and vessels of all classes.

The plant was faced with the task of equipping its production with additive technologies for solving various production problems.

The plant turned to Top 3D Shop, as the largest integrator of additive technologies in the region. The direct task was to select an additive unit with the possibility of direct printing of forms for a vertical injection molding machine.

The choice of a 3D printer was made in favor of an industrial SLA installation Shining iSLA-450.

The transition to Digital Production will significantly reduce the costs and time of production of small-scale plastic products, compared to traditional injection molding. Further - more about it.

The advantages of this solution

The advantage of this installation is the ability to work with virtually any photopolymer materials on the market.

In this case, the polymer

Somos PerFORM was chosen as the material, the main feature of which is the ability of the printed part to withstand temperatures up to 268 degrees Celsius.

- Water absorption: 0.20%

- Viscosity: ~ 1,000 cps @ 30 ° C

- Dielectric constant: 4.7: 60 Hz; 4.0: 1 KHz; 3.6: 1 MHz

- Dielectric strength: 26.3 kV / mm

- Poisson's ratio: 0.32

- Flexural Modulus: 10,000 MPa

- The modulus of tensile elasticity, MPa: 10,500 MPa

- Density: ~ 1.61 g / cm3 @ 25 ° C

- Tensile strength Rm: 68 MPa

- Tensile Strength: 42.2 MPa

- Bending strength: 120 MPa

- Tensile Strength: 32.8 MPa

- Shore hardness: 94

- Notched Izod impact strength: 17 J / m

- Elongation at break,%: 1.1

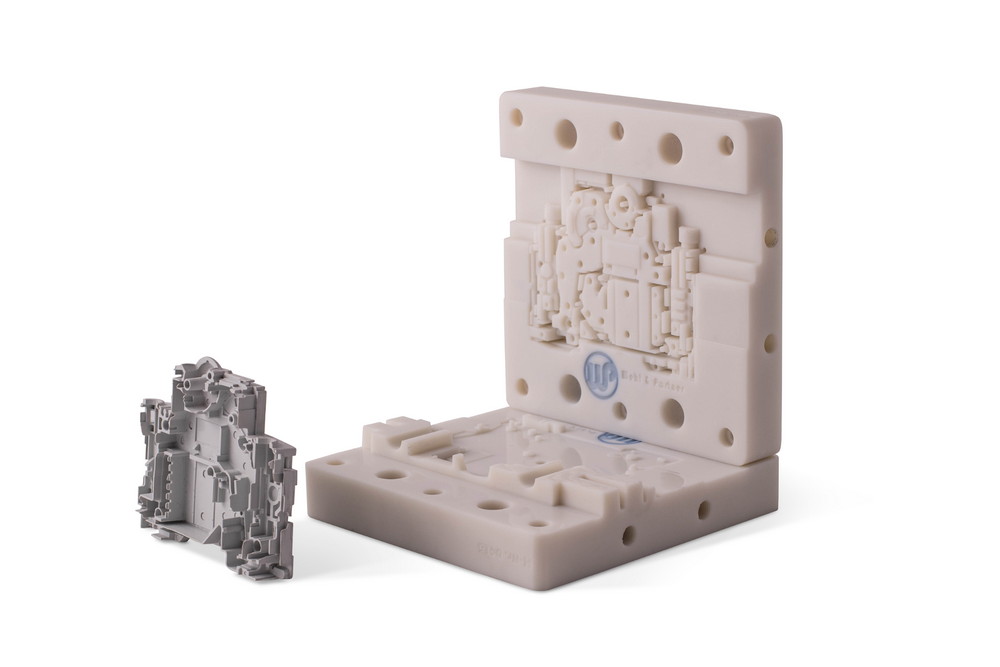

This technique allows you to print forms for a vertical injection molding machine on a 3D printer, which is much cheaper and faster than making them on a CNC milling machine.

Such forms withstand about 200 castings without loss of quality and are used for small-scale production.

Installation and Testing

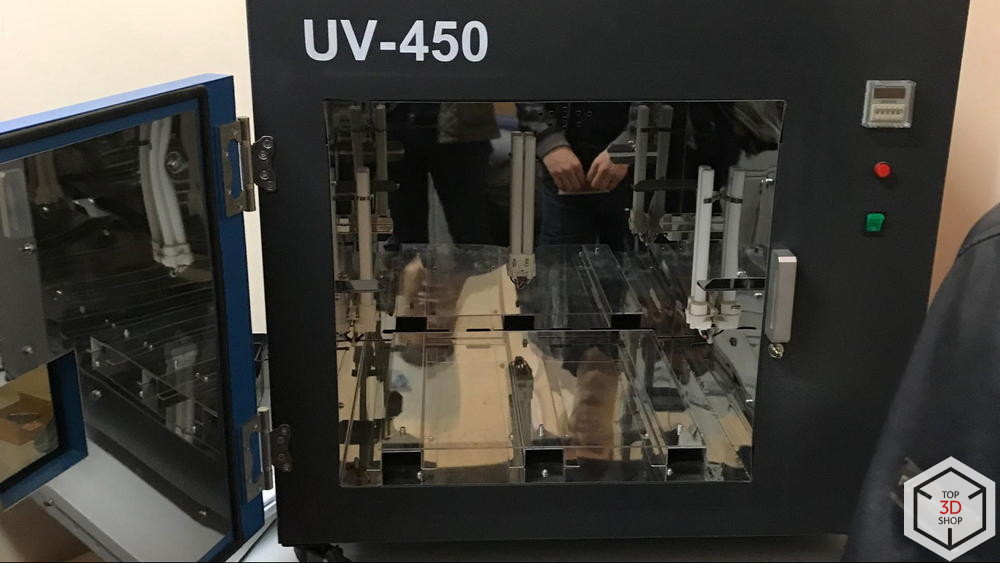

We have installed all the necessary additional equipment: a model washing chamber, a

ProJet Finisher oven for baking ready-made prints, a UV camera for illumination.

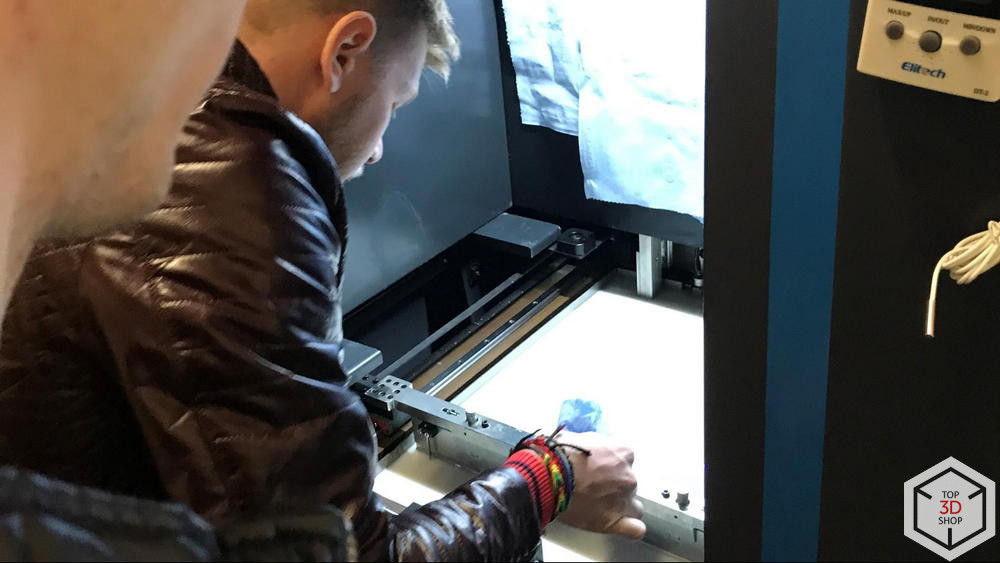

The printer was set to level, the main units were calibrated: laser system, building platform, squeegee level, resin sensor level. All manuals provided engineers who will work on it.

Conducted a test print, washing the model and hardening in the furnace.

Results, conclusions

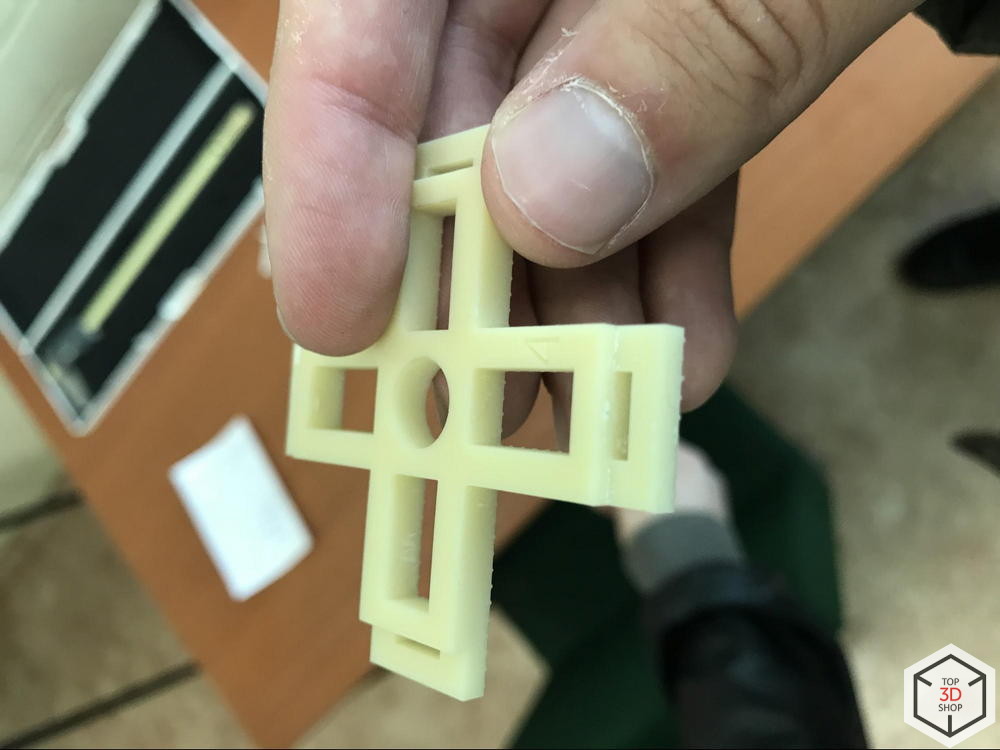

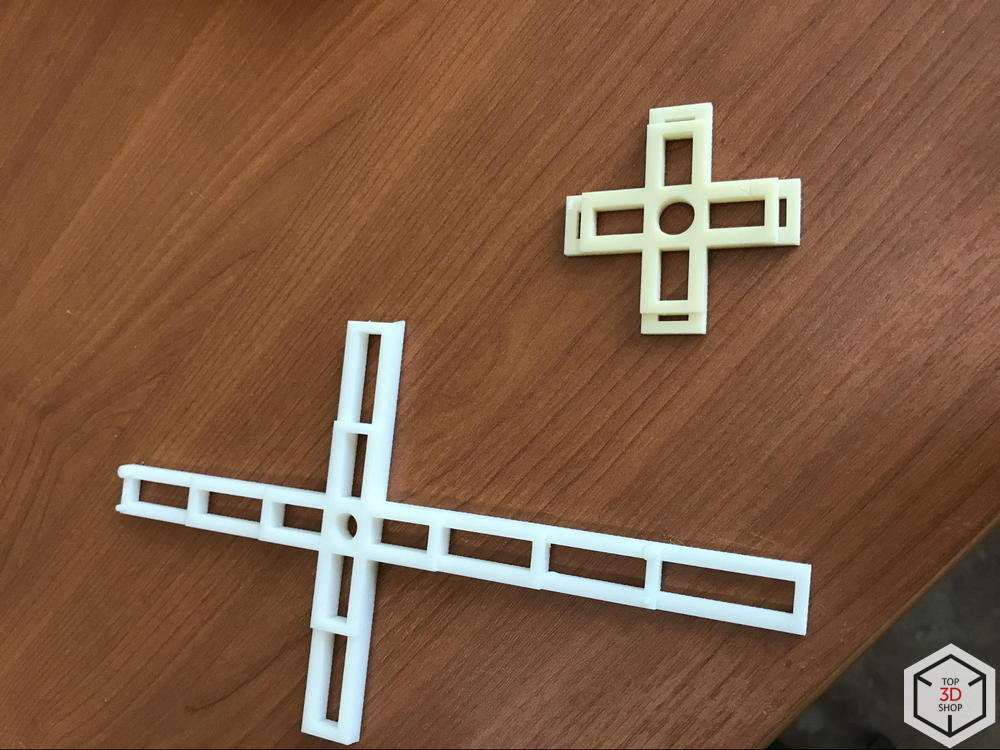

Shining iSLA-450 did a great job with printing with Somos PerFORM material and the resulting form will be tested on a vertical injection molding machine.

This is not a catholic cross, but our engineers are not the most religious people, they are just test samples for calibration, which allow us to evaluate the accuracy of the laser operation on all axes, the correctness of the geometry of the resulting part and the tolerance.

The price of an industrial solution with this technology starts from $ 100,000, which is more than justified for small-scale production and yields good savings - the milled shape is many times more expensive and takes longer to produce.

3D-printing is already rightfully takes place among the production processes. It does not replace and does not seek to replace each of them, but in many sectors it gives any production indisputable advantages - the speed of prototyping, the ability to accurately manufacture single and small-scale parts that are not inferior in terms of performance properties created by more traditional methods.

To modernize your production and select the necessary equipment, contact the leading digital integrator in Russia - in

Top 3D Shop .

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks: