Once the incident chronicles frightened us with the fires of tube televisions, now the 3D printers took over the baton. Most of them have protection against uncontrolled overheating of the table, and if the temperature exceeds the set temperature, the heater is turned off. Never deactivate this feature.

But MOSFETs and solid-state relays that control the heater sometimes “fly out”, after which the table warms up to the maximum achievable temperature, and it becomes impossible to disable it programmatically. Especially dangerous are heaters with network power.

The proposed device measures the thermistor temperature of the table, after revision, it can additionally monitor the heating of other points, such as nozzles and SD drivers. If overheated, it turns off the printer’s power supply.

With all the variety of sensors for measuring temperature, the author's choice fell on a 100-kilohm thermistor type 3950 with a negative temperature coefficient. It is used in the 3D printers themselves, so the device can test such thermistors.

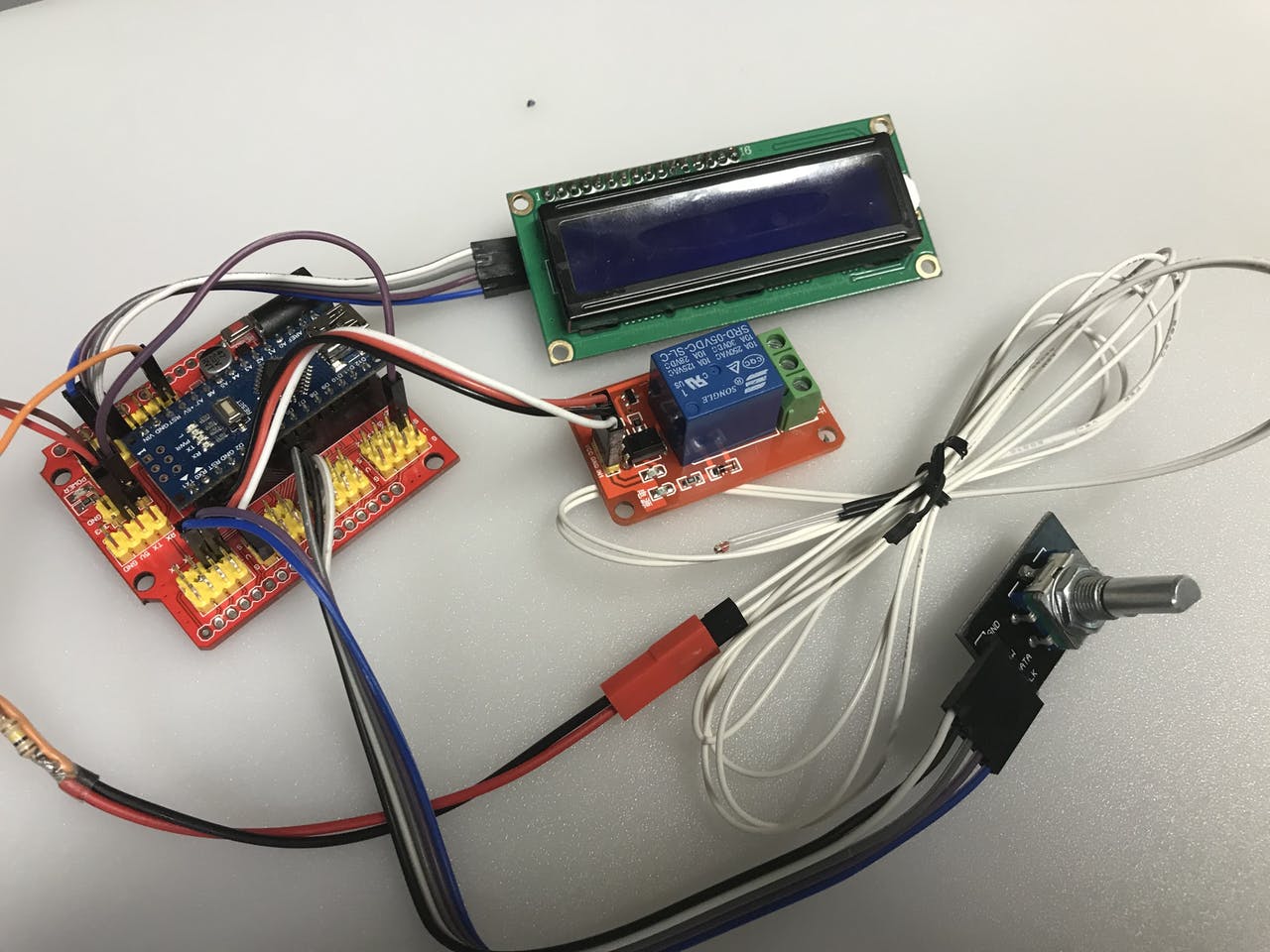

You will need:

- Arduino Uno or Nano (the author used Nano with an expansion module)

- LCD for 2 lines of 16 characters each with a serial interface and an adapter for the I 2 C bus

- KY040 encoder

- Relay module for Arduino with optocoupler and five-volt control (the translator would add a contactor with bridge contacts after it)

- Five Volt Sounder with Built-in Generator

- 100-kilomohm thermistor type 3950 with a negative temperature coefficient. Additional same thermistors, if you are going to make a device with multipoint measurement

- Input 3-pin connector for a standard computer power cord

- Grounding outlet for connecting your 3D printer

- 12-volt power supply, for example, from a router.

- Conductors, hardware, soldering iron, 3D printer for printing the device body, etc.

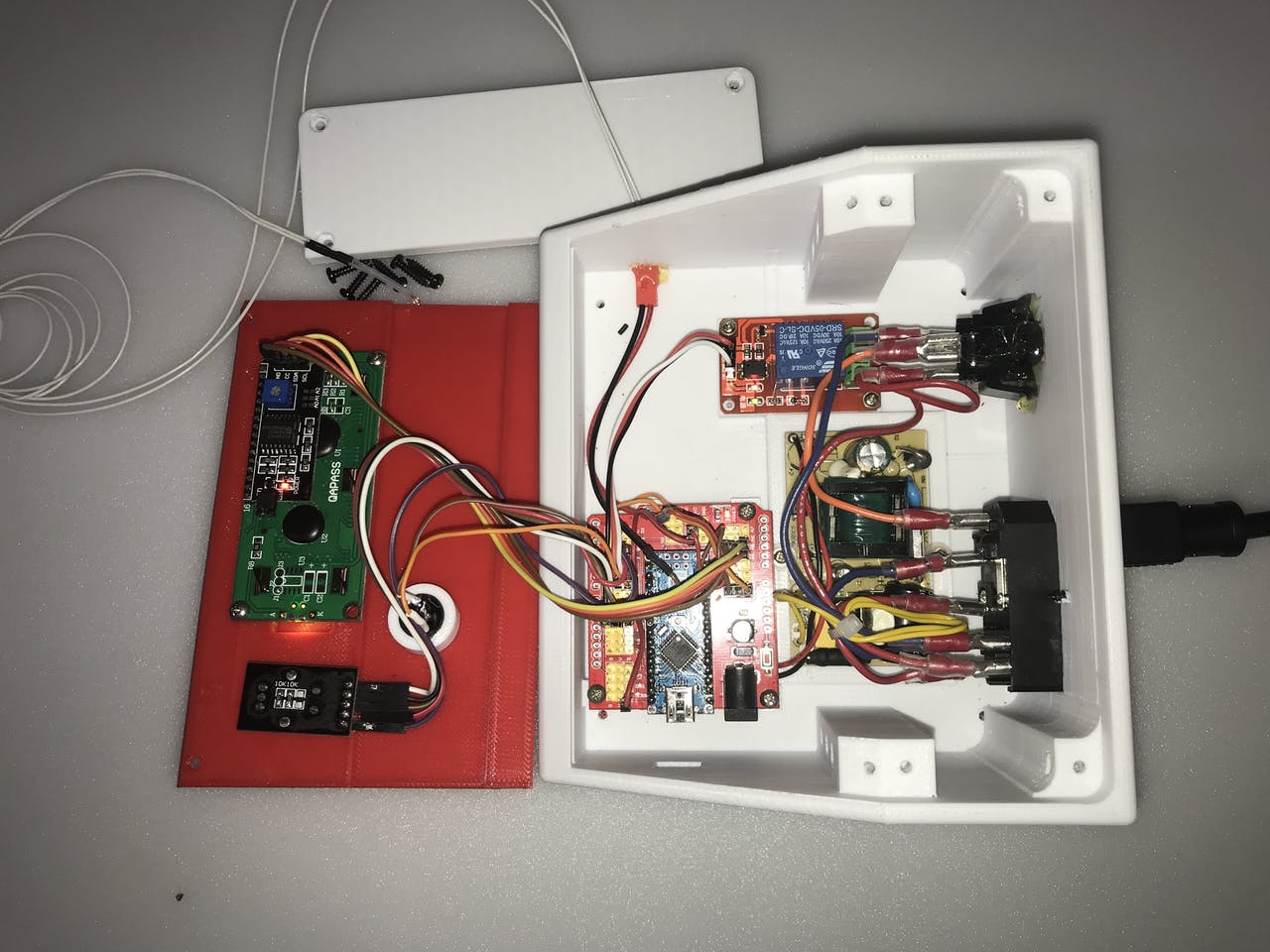

The author printed PLA body parts with 25 percent coverage. STL files are attached.

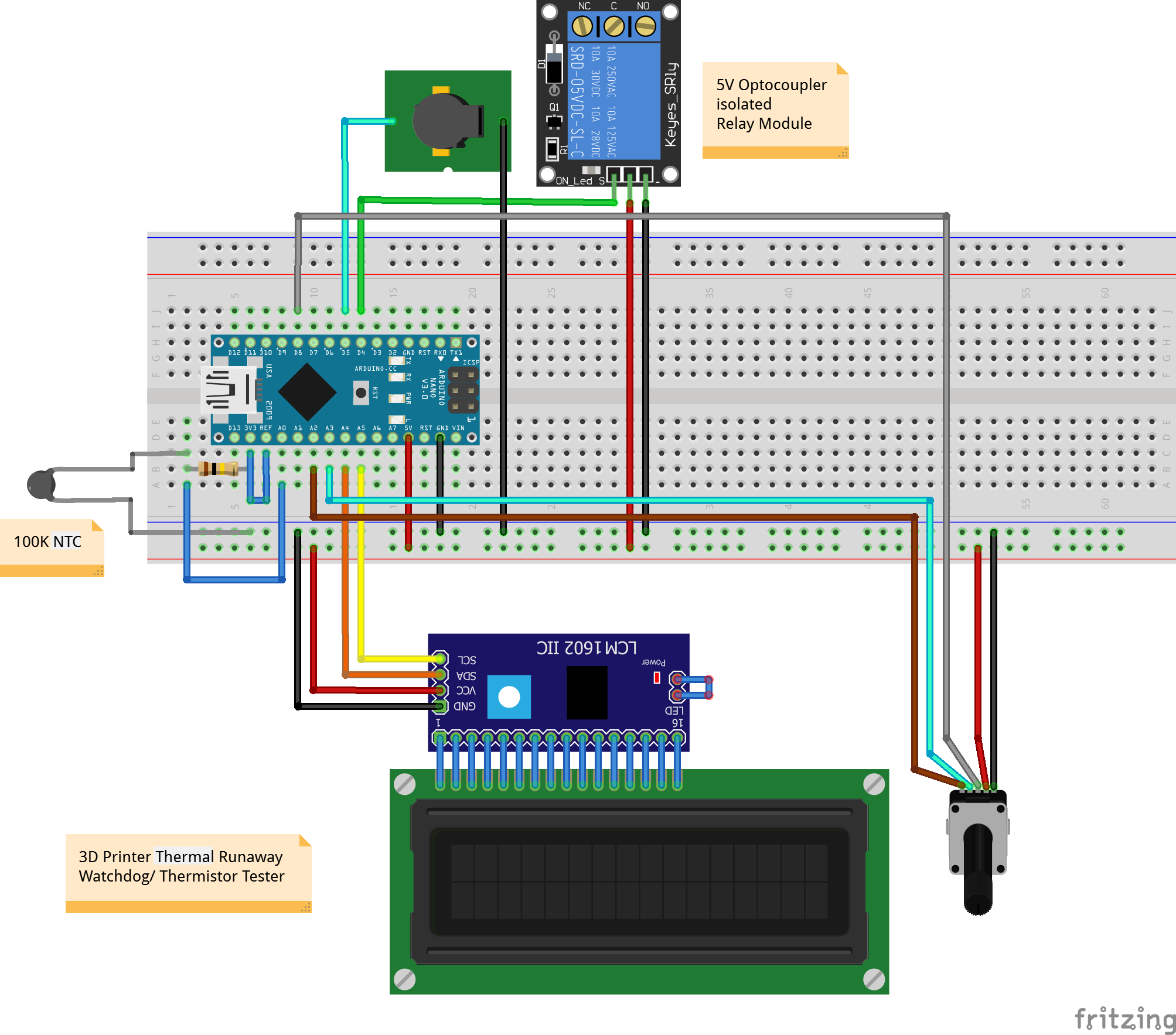

HousingFront PanelCapA penAt assembly be guided by the scheme and comments in the sketch. You can use Dupont jumpers or solder the wires to the pins on the board. Use wires that are long enough to fit everything into the case, and nothing was stretched when removing the front panel. The Vref line is connected to a 3.3V source for increased accuracy.

Schematic link

Schematic link

The input connector and the outlet can be placed on the case, and it is possible to make the structure non-removable by plugging it into the gap of the printer power cord.

Be careful when working with mains voltage .

The use of normally open contacts provides power to the printer only when two conditions are met simultaneously: the caretaker is powered on and there is no overheating. After detecting overheating, the printer remains off, even if the mains voltage is lost and restored, until the device is manually reset.

Before uploading the sketch, you must add the LiquidCrystal_I2C and EEPROM libraries to the Arduino IDE.

SketchAfter turning on the LCD, it will show the current temperature and the maximum temperature for the entire observation time.

Then the LCD displays the target temperature.

To reset the maximum temperature, press the encoder knob.

Set the target temperature by turning the knob, then pressing to save the change.

If overheating is detected, the “watchman” will turn off the printer and give a sound signal with a duration of one minute. The device will not resume power supply until manual reset.

To reset and resume power to the printer, press the encoder knob.

The maximum and target temperatures, as well as the overheating state, are stored in non-volatile memory in order to avoid spontaneous turning on of the printer in case of power failure and restoration of the mains voltage.