Among the companies that produce speakers, there are peculiar champions of innovation. One of the standards of an innovative manufacturer of acoustics can, without exaggeration, be the British company Monitor Audio. The creative search for their engineers began in the 70s and continues to this day.

This is a post about the technologies that Monitor Audio uses to create speakers, and the results they achieve using these technologies — an attempt to follow Monitor Audio's innovations and to summarize their experience in creating speakers (and in particular dynamic loudspeakers). I will touch on some facts of the company's history and key developments over the past 40 years.

Monitor Audio impresses many people, including me, with the fact that its innovations lie in the plane of practical electroacoustics and production technologies, and not in the sphere of “warm tube” marketing.

The beginning: the founding fathers and the first experience

We owe the appearance of Monitor Audio to the world market of acoustic systems to Mohammed Iqbal, Martin Colloms and Michael Bean, who in 1972 founded a small venture to produce acoustics in Cambridge.

It all started with a fairly large, three-way speakers, which corresponded to the trend of the time, which can hardly be called shelf. Rather, it was a kind of intermediate class between the traditional shelf monitor acoustics and floor systems, even special racks were included in the package, because not all the shelves could carry such a massive load.

At that time, the company did not produce its own speakers and used loudspeakers from other companies, such as KEF, EMI, B & W, Peerless. Shells were developed by the company, but ordered from third-party manufacturers. In other words, the engineering part of the development was the design and optimal calculation of the hull parameters, the design of the circuitry and the design of the crossover, as well as the exterior design / decoration of the speakers, and the production function was reduced to high-quality assembly.

Contemporaries of the first series of this acoustics noted that the manufacturer, with all the conceptual screwdriver, does not save on high-quality components. Moreover, these reviews were in the audio press that was still emerging then (which at that moment was a refuge for technical gifted enthusiasts, and not a collection of marketing and subjectivist myths as it is now). The generosity of the components is the feature of the Monitor Audio products that has been preserved until now.

Seventies

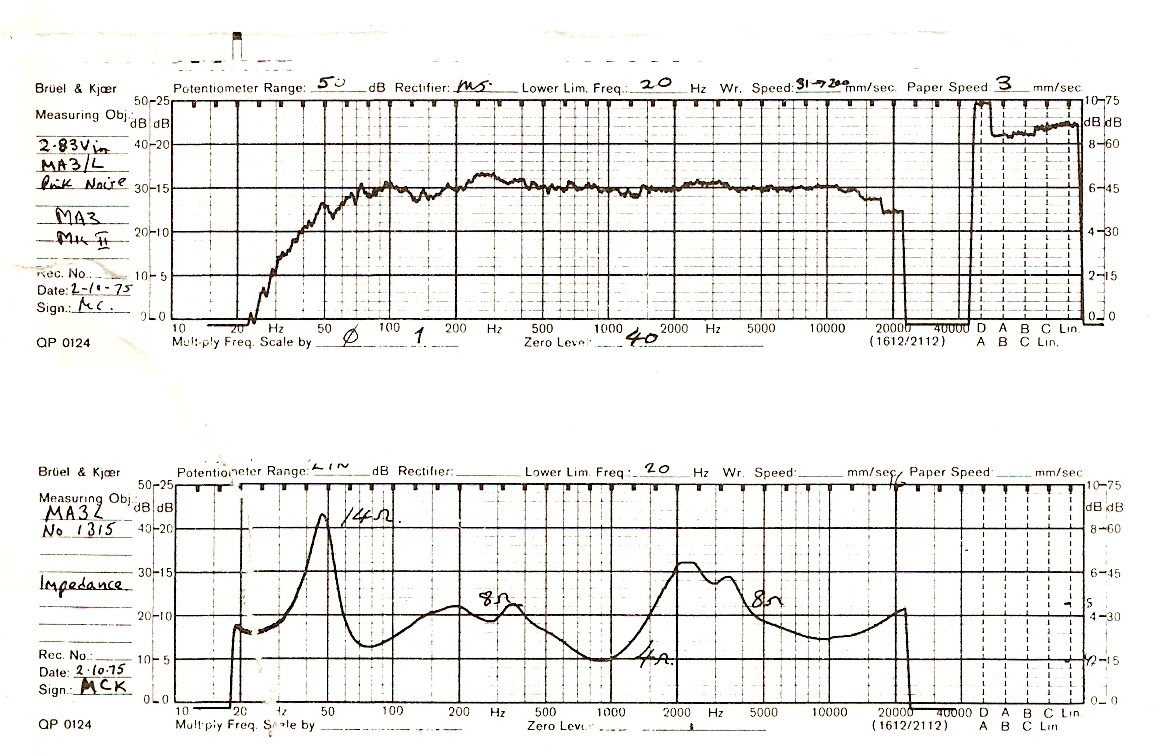

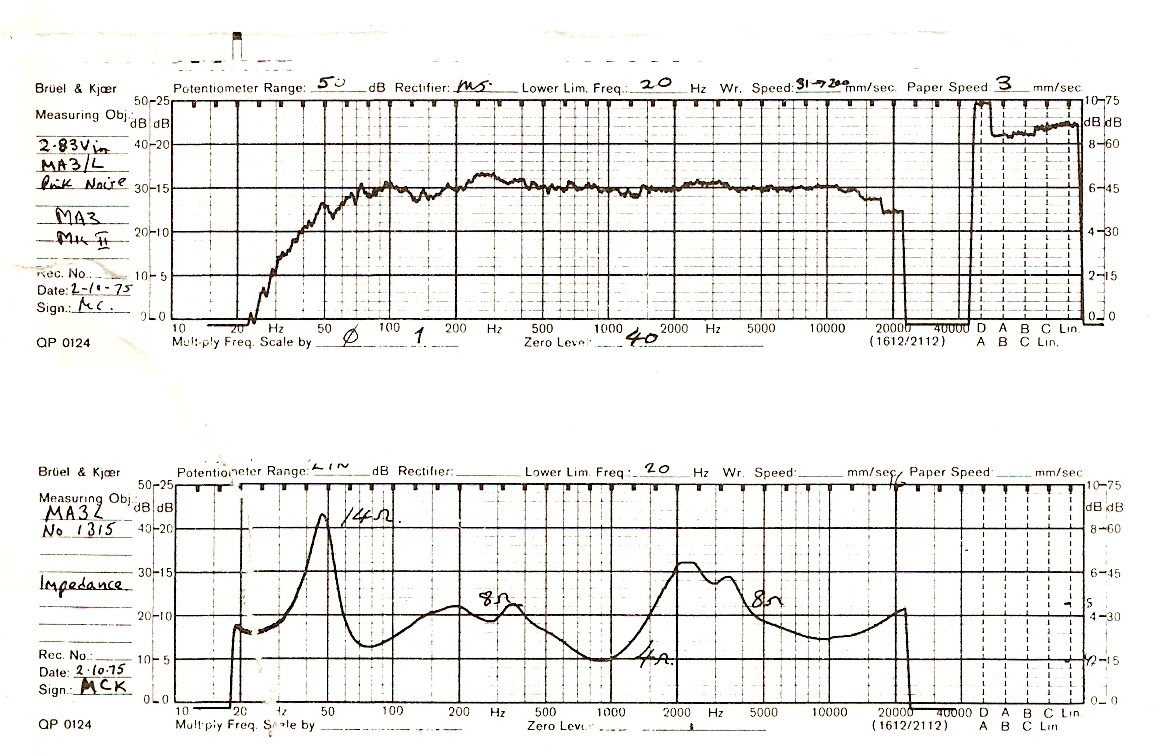

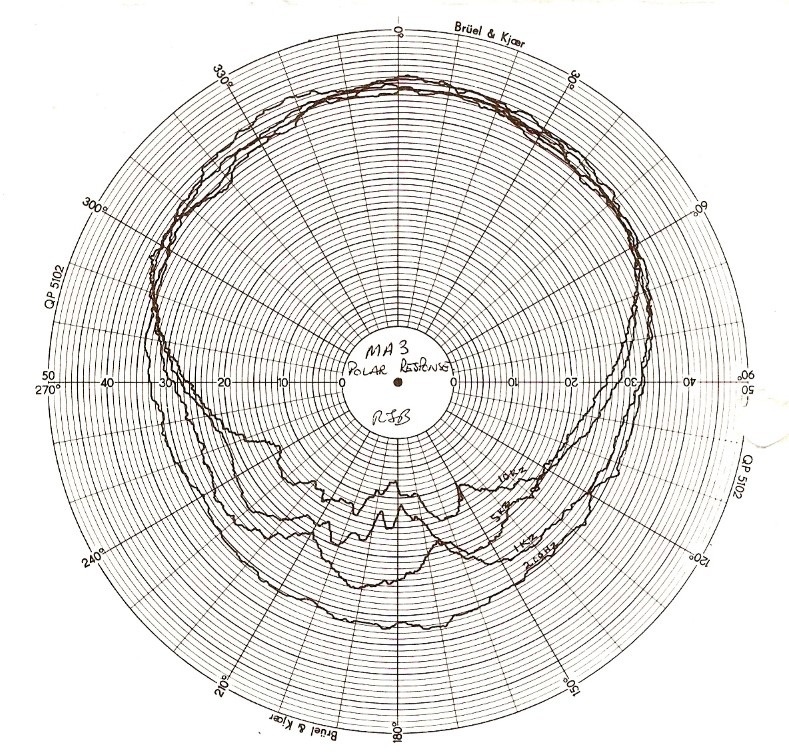

In 1974, the company created the first speaker, which draws on the status of the legend of its time - MA3, a huge (height 715 mm, weight 27 kg) three-way floor system with highly sensitive EMI drivers. A non-trivial solution was the use of oval low-frequency speakers with a fabric sandwich membrane coated with polymers (the form was used to increase the diffuser area).

The design of the low-frequency driver made it possible to reproduce frequencies ranging from 40 Hz, with an unevenness of + - 2 dB and a sensitivity of 96 dB, which today is a rather impressive result.

In general, the characteristics of the device are as follows:

Over time, the company realized that it was necessary to use loudspeakers from the same manufacturer and produce the enclosures themselves. Hi-fi, as a phenomenon and standard at that time, was just beginning to develop rapidly, and the approaches that existed at that time required solutions from engineers that would drastically affect the improvement of fidelity.

In 1976, the company moved to one of the London suburbs and opened its own factory for the manufacture of buildings. Somewhere at the same time, Monitor Audio began to cooperate with the largest British manufacturer of speakers ELAC (not related to the manufacturer of the same name from Germany).

The second hit of the seventies, which reflected cooperation with ELAC, is MA7, created in 1977, a more compact 2-way bookshelf monitors with dimensions (HxWxD): 405x228x203 mm and weighing about 7 kg. They also used fabric speakers with a polymer coating, which became at that time a popular alternative to classic cellulose diffusers. Technical characteristics can be judged from the documentation for this equipment, which has been preserved from that time.

Even in the early stages of development, the company began experimenting with materials for diffusers, when most manufacturers preferred cellulose, in Monitor Audio experimented with composite fabric membranes.

Eighties

By the end of the seventies, the company won the status of one of the leading British manufacturers of innovative acoustics, and also organizes the release of its own speakers. The decision to abandon third-party manufacturers for several reasons:

First - you can adjust the speaker under the design of the AU, and not vice versa, when the parameters of someone's speakers determined the calculated values of the buildings.

Second, you can develop new types of loudspeakers, which will have unique (compared to other) properties.

Third, it is possible to reduce the cost of components and streamline production by adapting the speaker to the specific product (AS) as much as possible.

So as a result of a scientific search, Monitor Audio implemented the idea of metal diffusers. In the eighties, very few people made woofers of metal, except for Monitor Audio I can think of ALR Jordan (Germany) and Acoustic Energy.

An effective cooling system, implemented through the installation of a special metal dome and additional ventilation elements, has become a feature of the Monitor Audio metal emitters.

Also, Monitor Audio was the first to use ferromagnetic fluid in the gap between the magnet and the coil (the

technology came from the space industry ) and used a metal frame for the loudspeaker coil.

The first speaker with an aluminum tweeter was Monitor Audio R852MD, which was released in the 1986th. The technology created for the first metal RF drivers Monitor Audio, is used to this day.

Characteristics:

- Frequency range: from 42Hz to 22kHz (from 70Hz to 20kHz ± 4dB [with anechoic measurement]);

- Crossover separation: 3.5kHz [18dB / octave]

- Sensitivity: 98dB max per 1 m, 20W for 96dB per 1 m

- Resistance: 8 Ohm

- Recommended rated amplifier power: 8 to 30W

- THD: not more than 0.7% (for the whole range of reproducible frequencies)

- Dimensions: 228 x 405 x 203mm

- Mass: 6.75g

Later, in 1988, the company's engineers improved the high-frequency metal emitters, which led to the emergence of a new technology, called Gold Metal Dome (later - Gold Dome C-CAM). Technically, the innovation allowed “pushing” the first resonance of the tweeter dome to 35 kHz, i.e. far beyond the limits of human perception. The golden glitter of the anodized alloy from which the loudspeaker was made has become a characteristic feature of these twitter. Gold, contrary to popular belief, is naturally not there.

The appearance of the RF driver Gold Metal DomeInterestingly, the sign for the 80s AC R852MD was developed by renowned designer Robin Marshall, who, having left the company, founded Epos Acoustic, which produced the ES14 speakers, which were no less legendary for their time.

ES14

C-CAM

The last major and perhaps one of the most significant innovations in the company's history of the 80s was the development of ceramic-coated metal membranes for midrange / woofer drivers. The technology is borrowed for audio from the aerospace industry, where it was used to produce jet engine components.

Characteristic appearance of a C-CAM radiator

Characteristic appearance of a C-CAM radiatorThe use of this technology in serial products applies equally to the 90th - zero years and the present time. This technology of production of diffusers, called C-CAM, at the moment is the basis for almost many Monitor Audio devices.

Considering that this technology has become the basis for the production of metal-ceramic Monitor Audio speakers, it makes sense to dwell a bit more on the technical process. In the production of diffusers to ensure uniformity (solidity) of the material, the aluminum-magnesium alloy undergoes a special procedure for removing residual stress, consisting of three stages. After that, anodizing is applied to create a ceramic layer 50 microns thick.

Thanks to the use of this technology, the stiffness and resistance of the material to bends and stray resonances becomes much higher than that of traditional metal loudspeakers.

From the nineties to the present

In 1991, the first serial speakers with ceramic-metal diffusers and the first speaker, based entirely on them - Monitor Audio Studio 10, appeared. This system was positioned as a studio speaker, and at the same time won not only professionals, but not music audiovisuals.

It was a classic bookshelf two-way speakers with the following characteristics:

- The frequency range from 40Hz to 20kHz ± 3dB.

- The frequency of the crossover is 3 kHz.

- Sensitivity 88.5dB / W / m (2.83V).

- Nominal impedance of 8 ohms.

- The recommended amplifier power range is 20–200 W (8 ohms).

- Dimensions: 20 x 25,5 x 40.

- Weight 8 kg each column.

Frequency response graph of Monitor Audio Studio 10 (it can be seen that the resonance peak is superseded outside the audible range of 25 kHz)

It would not be superfluous to note that with the innovations that were truly unique for their time, the company did not always successfully show itself in the consumer and professional audio market in the 90s. In 1998, this led to a thorough reorganization of the model range and structure of user rulers.

We must pay tribute to the marketers of the company (in this case, without sarcasm), who, based on sufficiently deep research of the audio market, created a pyramid of classes, which still does not lose relevance today. The pyramid consists of five levels, which well reflect the categories of people acquiring speakers:

- Monitor (formerly known as Monitor Reference) is a base class with high fidelity playback. Earlier in this category the decor would be absolutely minimalist. From the current year, in order to attract young people, the manufacturer has proposed colored speaker diffusers.

- Bronze is a high-quality sound, as well as a memorable design and a comparatively not stingy finish, for people for whom the conformity of form and content is important.

- Silver is a premium class, where technologies go beyond the classical ideas of high fidelity of reproduction, i.e. accounting for even minor nuances. Finishing status materials (natural veneer, varnish).

- Gold - uncompromising, with the highest possible components, you can without exaggeration be called High-End.

- Platinum - the best of what the company could do, flawless acoustics, turned into a luxury item.

A little more about technology

Rigid Surface TechnologyZero also began with a landmark development. In 2000, the so-called RST (Rigid Surface Technology) was developed. The company's engineers were faced with the task to once again increase the strength of the mid-frequency / low-frequency emitter membranes in order to achieve greater sound pressure while maintaining the size and without increasing distortion, as well as to reduce the propagation of standing waves.

To implement the task, a principle similar to Japanese origami was applied. To create stiffeners, small hemispherical pits were applied to the surface of the diffuser, the diameter of which increased from the center to the periphery of the diffuser.

MMP (Metal Matrix Polymer)In 2003, researchers of the company in serial practice successfully introduced another technology, which became a kind of budget alternative to C-CAM. Innovation was first used in speakers of the Radius series.

The essence of the technology is melting into polypropylene (the basis for creating a diffuser) metal particles under high pressure. As in the RST, the thickness of the diffuser was made variable to increase strength. As a result, the weight and cost compared with the conventional polymer membrane almost did not increase, and the strength increased many times over. The technology is successfully used in modern budget speakers from Monitor Audio.

Antiresonant compositeAnother interesting technology used in creating the Monitor Audio system is ARC (Anti-Resonance Composite). Like many others, ARC was not originally an acoustic technology, it was borrowed from the automotive industry.

The Monitor Audio development team revealed that panels made of polymer with mineral additives made it possible to reduce resonances in the frame elements of the MF loudspeakers and acted as a kind of damper. Unfortunately, only the owners of the pathos flagships from the Platinum series for non-poor audiophiles can evaluate these antiresonant properties of the material.

Composite Diffusers Monitor AudioRDT (Rigid Diaphragm Technology) technology has appeared relatively recently and is currently used only for the flagship Platinum line. In fact, this is another “wrench” in the direction of reducing the mass and increasing the strength of the diffuser.

The technology involves applying an anodized cermet layer of C-CAM on a cellular structure woven from strong ultrathin fibers of the polymer material Nomex. Test results showed that RDT 40 microns thick (twice thinner than a human hair) is lighter and 150 times stronger than C-CAM 200 microns thick.

HiVeII (High Velocity)Innovation touched not only the speakers. One of the interesting features was the use of so-called. HiVeII phase inverter (High Velocity). The bottom line is that human hearing is very sensitive to sound delays. The phase inverter, in addition to the fact that it allows to enhance the bass, also causes such delays. In order to eliminate them, longitudinal cuts are used in PI tubes, which accelerates air flow and reduces turbulent phenomena.

Total

To describe all the innovations that Monitor Audio applies, one article is hardly enough. I chose the most significant, in my opinion. The experience of innovative developments of this company is very interesting and instructive for some other manufacturers, who for many decades have not changed anything and live thanks to the once earned reputation and myths about the value of archaic technologies. Traditionally, I propose to participate in the survey below.

Jeans

A number

of high fidelity

loudspeakers are presented in our

catalog , among others

Monitor Audio .