The strongest impression of the Lakhta Center skyscraper you get when you look at it from the bottom, from the foot - up and it seems that it goes somewhere in celestial infinity. And it was then, and not from distant urban angles, that captures the spirit of heights and power. And somewhere around the tenth stage comes the thought - it’s good to know exactly what they were building sensibly and conscientiously. And twice it is good that we have it, monitoring. Development of domestic programmers, especially for the complex. The magic thing, to prevent the slightest possibility of bad future development options. Under the cut - all about how it works.

Any building is exposed to many external forces. Changes in temperature and humidity, wind pressure, pressure of snow masses, soil heterogeneity and its change over time. On skyscrapers with their size, weight and complexity of the design, this effect increases many times.

The occurrence of deformations, overvoltage zones of the structure is dangerous even for small cottages, what to speak of skyscrapers, where the consequences of unnoticed changes in the structure are disproportionately more critical.

Therefore, in all modern high-rise buildings, deformation monitoring systems are applied, involving the use of a whole range of control tools.

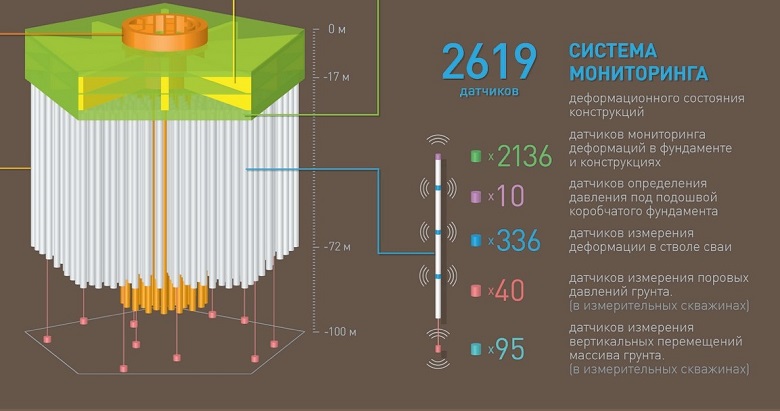

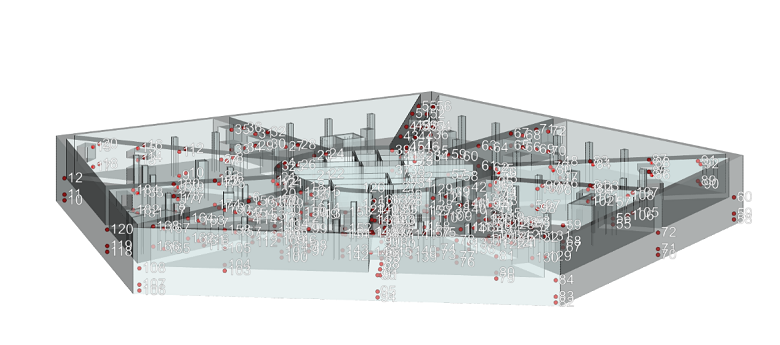

The magnifying glass in this tool, of course, is not included, but a lot of sensors are included. There are about 3 thousand of them in Lakhta Center, and they are located in all key structural elements of all the facilities of the complex.

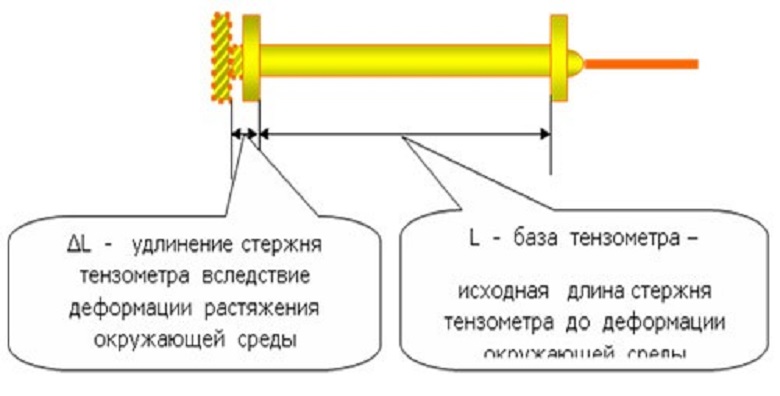

The largest group is strain gauges located on the front edge of the deformation defense. This is one of the most reliable and durable, and therefore common sensors that are used to measure deformations and stresses. It's all about the simplicity of design.

In essence, a strain gauge is simply a piece of high-strength steel wire - a string stretched inside a hollow metal tube between two end blocks. When the structure is deformed, the distance between the end blocks changes, along with it the string tension force and, accordingly, the oscillation frequency changes. The change of state is converted into digital signals, which are transmitted through multiplexers and data loggers (data loggers) to the monitoring system.

Strain gauges are welded to metal beams, embedded in concrete, and the lack of maintenance is compensated for by a multiple reserve of quantity. It is even installed in the mines below the pile field to the geodetic marks minus 100 m.

Clickable

ClickableThe signal from each of about 2.5 thousand strain gauge sensors Lakhta Center is transmitted to the monitoring system, and even the failure of individual strain gauges - although there’s nothing to break there - will not really affect the accuracy of the overall picture of the structure's condition.

Clickable

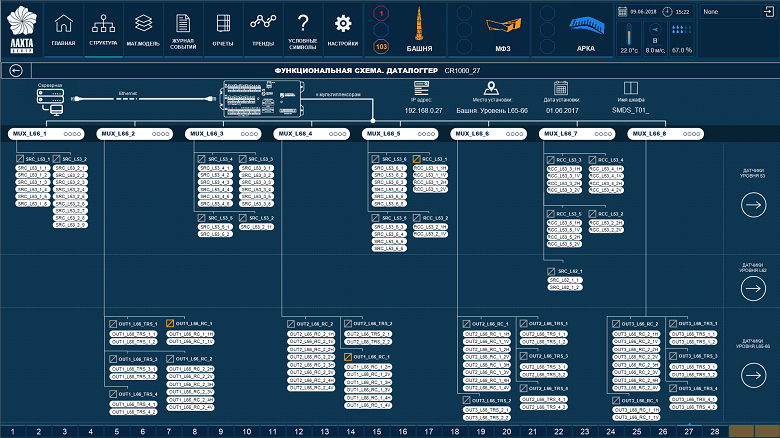

ClickableInformation from strain gauges is accumulated once an hour and transmitted to the server every six hours. This is more than enough for such a sluggish in nature process as deformation. It is quite another thing that building vibrations are a fast, continuous process, and by changing the characteristics of the vibrations, it is also possible to identify changes in the structures. To do this, every few floors of the Lakhta Tower of the Center, control points are set up, equipped with accelerometers - oscillation meters.

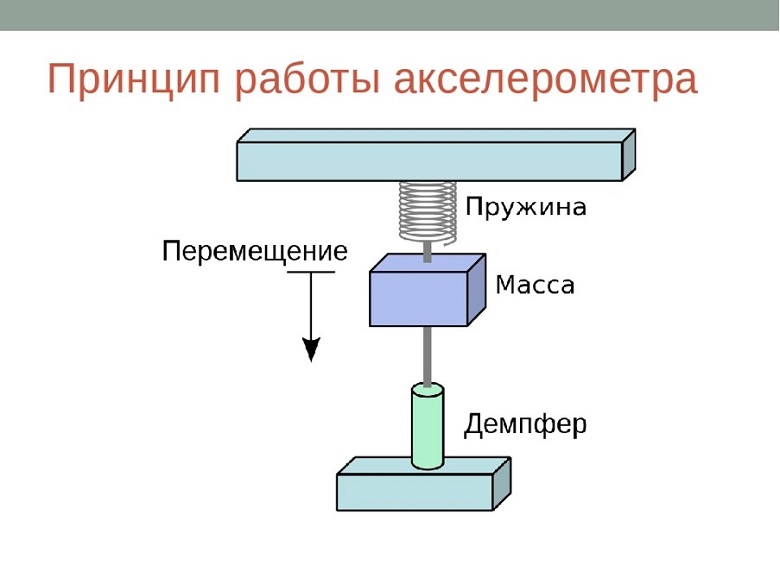

The device is the simplest accelerometer. The load is attached to the spring. Damper suppresses the oscillation of the load. The greater the apparent acceleration, the more the spring deforms, changing the instrument readings

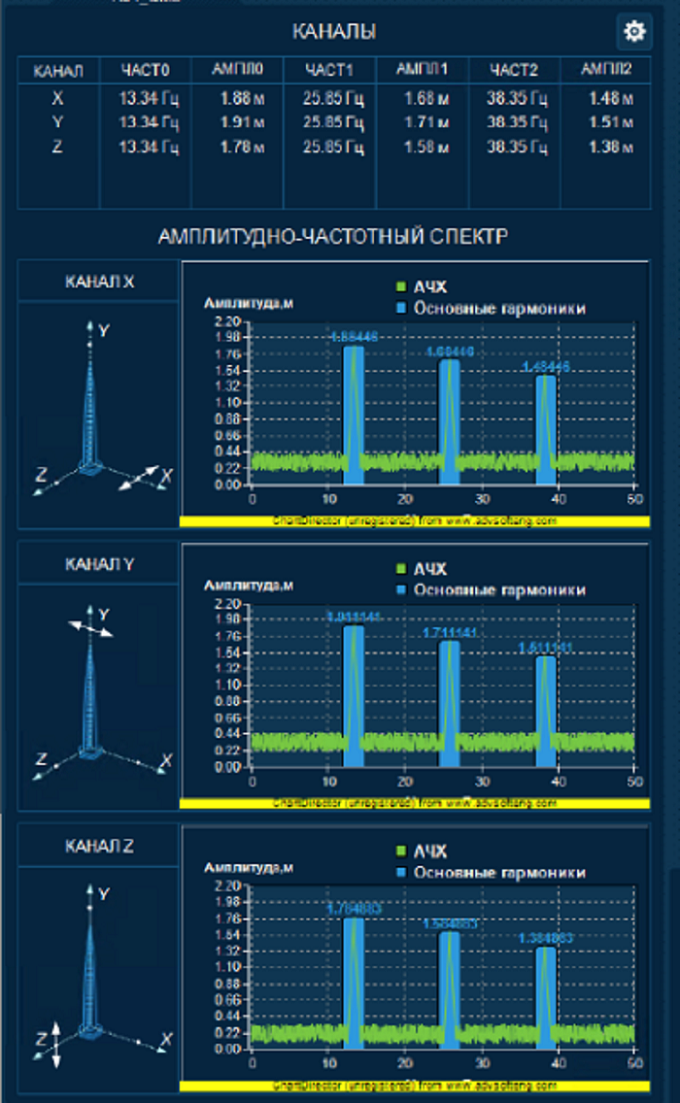

The device is the simplest accelerometer. The load is attached to the spring. Damper suppresses the oscillation of the load. The greater the apparent acceleration, the more the spring deforms, changing the instrument readingsBased on the measurements, the amplitude-frequency characteristic of the structural elements of the building is constructed, and the deviation from the norm of frequency or amplitude is a signal that something went wrong.

Another type of sensor, inclinometer, measures the angle of inclination of the structural element on which it is installed.

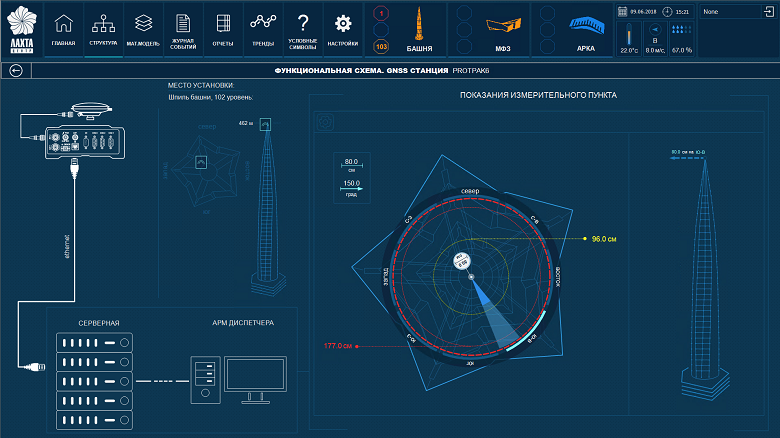

A modern measuring complex is installed in the spire of the tower of Lakhta Center. With the help of a GNSS station, the spire is tracked in a two-dimensional coordinate system: the satellite, roughly speaking, takes a picture that the tower draws with a spire depending on the strength and direction of the wind.

Clickable

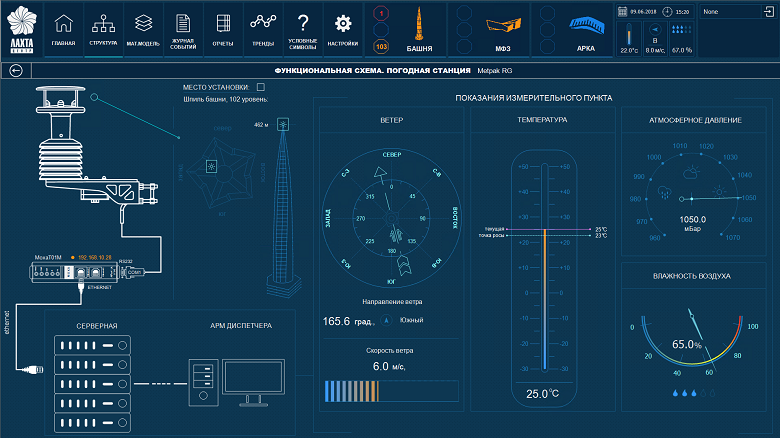

The weather station, in turn, will assess the dependence of the state of the structure on the readings of humidity, temperature, wind speed and direction.

Clickable

ClickableA tachometer mounted on an arch, on a reference point, measures with a laser the angle of inclination and distance, the displacement of which in either direction may indicate a change in the location of the structure, for example, due to precipitation.

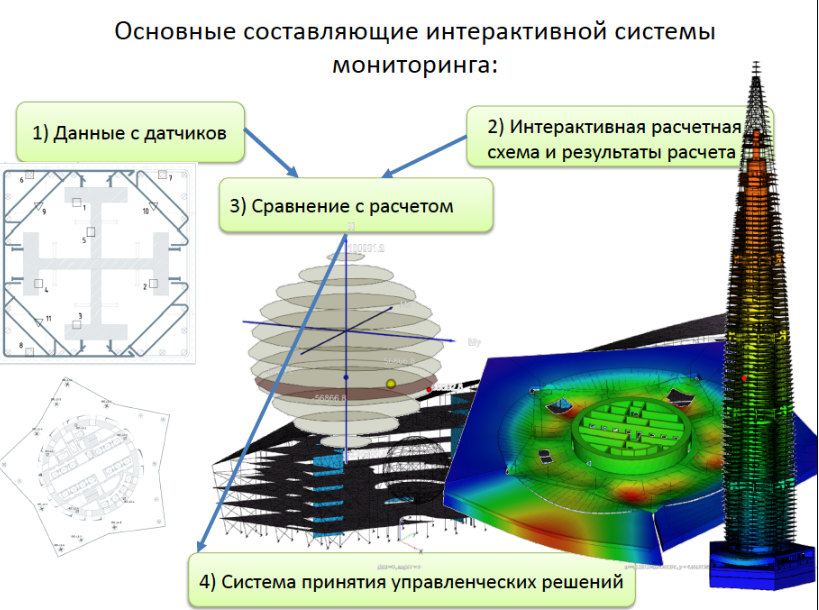

But the main feature of the automated monitoring system of engineering structures of Lakhta Center is not in the variety and number of sensors. The sensors are crammed with any modern high-rise building, and in Burj Khalifa there are not less. But the system of analysis of information received from the meters in the St. Petersburg Supertoll is truly unique. It is based on a constant comparison of the real picture of the state of the Lakhta Center buildings, based on the sensor readings, with the predicted values of deformations.

The calculation of the stress-strain state of structures is carried out on the basis of a certified software package for structural modeling based on the

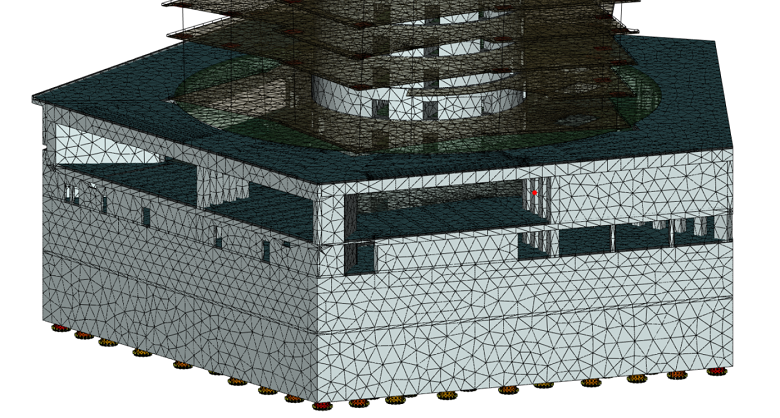

FEM -models finite element method of the company PI Georeconstruction.

The design model of buildings is created jointly with the foundation and the foundation (array of soil), since the underground and above-ground parts of the building work together, mutually influencing each other. To create a building design model, the finite elements of the system are endowed with the properties of real materials with precisely defined current mechanical parameters.

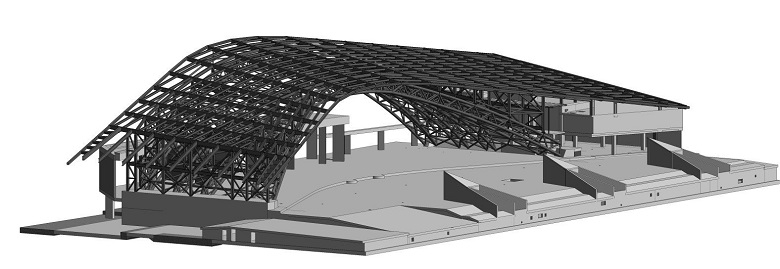

The FEM model is built using a project 3D model (BIM), taking into account the actual geometry of the building, which can be adjusted during construction and operation. That is, in the interactive model, the original BIM model is refined and the characteristics of real materials from which each element is made are laid - the class of concrete, the thickness of the floors, the section of beams, etc.

Vladimir Lukin, head of the Lahta Center for Reinforced Concrete Structures, oversees the creation of the project of the Lakhta Center monitoring system :

- Comparison of monitoring data with an interactive finite element model makes it possible to manage the model parameters, namely: change the design scheme in accordance with the construction of the building, change the parameters of materials and structures in accordance with the executive documentation, change the magnitude of the loads in accordance with the actual pattern of loading structures . Thus, the finite element model of buildings adapts as the external conditions change and gives predictions that are more and more close to the real values recorded by the monitoring sensors.

On the basis of the performed calculation of structures in the software environment, all possible versions of the development of deformations are checked. Thus, the emergency limits of sensor readings, scenarios and algorithms for the development of deformations are found, the development of criteria for assessing the real technical condition - stability, residual life and durability, is being developed in accordance with the indications of the sensors monitoring the structures. Evaluation criteria include absolute and relative deviations of structures, take into account the behavior of the building as a whole.

Dmitry Babichev, project manager at Telros :

- The materials of which the building is built, always have differences from those that were laid in the design model. That, in turn, affects the deviations of real loads from the calculated ones. The mathematical model that is used in the automated monitoring system for the state of engineering structures of Lakhta Center is a model of a real object. And based on the analysis of sensor readings, it can already be stated that this real object turned out to be even much more rigid than the design model, and so it was built with a more than serious safety margin.

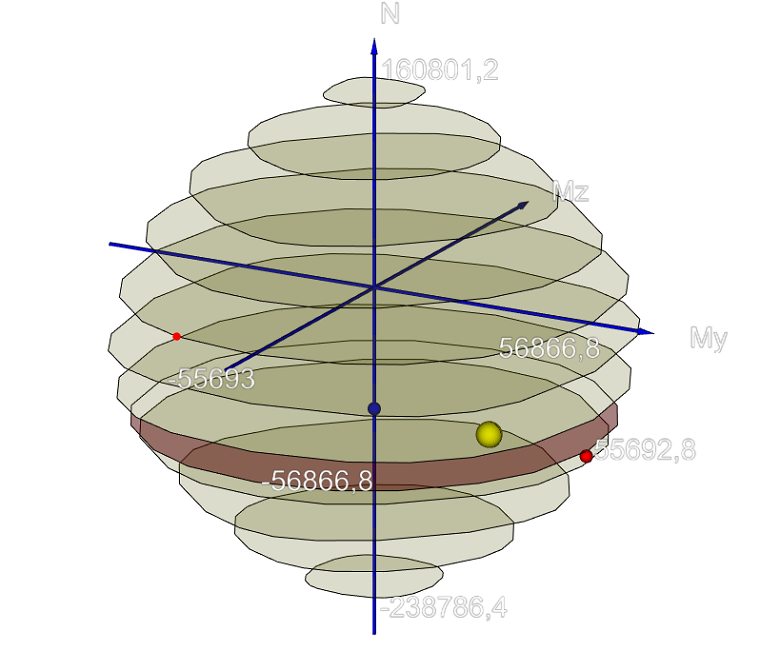

The layout of the measuring equipment on the three-dimensional design scheme

The layout of the measuring equipment on the three-dimensional design schemeThe FEM model is a true digital twin. The same as, for example, the digital twins of the spacecraft, which are used in NASA to simulate situations occurring in space. After all, there the collection of information from sensors using telemetry is also the only way to monitor the situation, identify problems, and, after analyzing and simulating what is happening on the orbit on earth, look for possible solutions to problems.

The Lakhta Center deformation monitoring system monitors the state of supporting structures in real time with a survey rate of up to a thousand readings per second, accumulates statistics almost from the very beginning of building construction, monitors changes as load increases and will continue to do so during operation. Moreover, the system can be trained and due to this, the building model can be automatically changed taking into account the actual sensor readings.

Wires from the first sensors in the piles - they were installed at the very beginning of construction

Wires from the first sensors in the piles - they were installed at the very beginning of constructionAnother difference of the monitoring system used in Lakhta Center from analogs in other skyscrapers is the presence of not only an emergency border of deformation of the building elements, but also warning. On the basis of the same mathematical model, taking into account the real state of the building, an area of permissible values is built, in which there are no deviations from the forecast indicators, and a precautionary area, which, from the standpoint of SNiP, is still far from the emergency state, but going into it is an occasion making.

Yellow zone - a warning deviation from the predicted values, red - emergency

Yellow zone - a warning deviation from the predicted values, red - emergencyDespite the fact that all the data coming from the sensors are analyzed automatically, decisions are made by people. The dispatcher, upon receipt of an alarm signal, informs the duty officer, who conducts a visual inspection, takes a photo tied to the required point in the system and prepares a report. This report analyzes the design engineer and decides on the recalculation of the FEM model if the reasons for the change in the parameters are noncritical, and are associated, for example, with the natural and predicted draft of the building. Otherwise, the alert is received by the chief engineer, who can decide even to evacuate. But, given the safety margin of Lakhta Center, for the development of such a scenario, an external impact is required at the level of a six-point earthquake. A signal about the approach to the emergency boundary of the development of deformations is automatically transmitted to the services of the Ministry of Emergency Situations.