Hello everyone, with the company

3Dtool . Today in our review a 3D printer of impressive size, which takes professional 3D printing to a new level.

It is called

CreatBot D600 , and comes in a fairly durable, wooden box.

Let's start unpacking it

The printer is packed just fine, foam is laid on all sides, all glass is sealed with packing film to avoid scratches, and inside the moving parts are fixed with nylon ties.

CreatBot D600, it is not by chance that it has these numbers in the title, because the size of its working area is

600 mm x 600 mm x 600 mm and the useful volume is

216 liters.

Also its main advantage (in addition to size) is a dual printing unit with two separate extruders.

The size of the workspace is impressive, because there are not many FDM 3D printers on the market that can compete with the D600 in this respect. In this case, the dual print unit can print support using soluble materials. These features allow the

CreatBot D600 to create complex large-sized models. That in itself is a rare combination and is highly demanded in the market of professional 3D technology.

Housing

The body of the printer is completely metal, and its overall dimensions are

915 x 845 x 1085 mm. The weight of the printer is

125 kg, which, coupled with a rather impressive stiffness, has a beneficial effect on reducing vibrations during printing.

On the case there are many opening doors and windows, opening access from either side to the printed model.

Due to the fully enclosed case, the possibility of external interference in the operation of the printer is eliminated, the noise level during operation is reduced and the temperature inside the chamber is kept constant so that the product does not deform during printing. Because of this, the printer allows you to easily print with high shrinkage plastic, for example, derivatives of ABS plastic or nylon.

Place for installation of material coils is located behind the case.

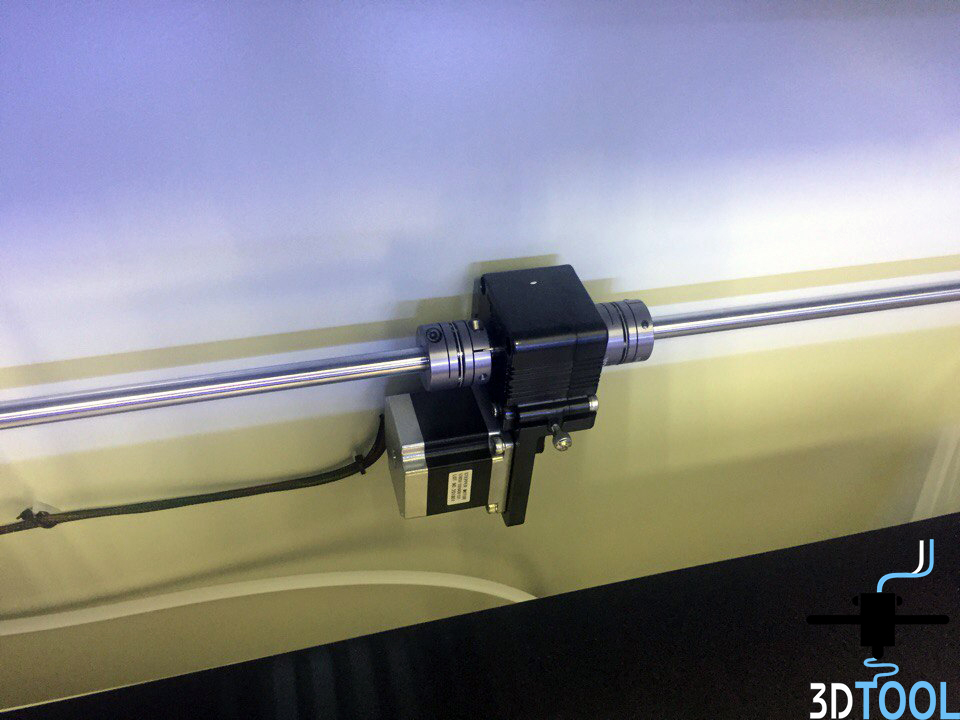

Kinematics

Designed as a single unit with a belt, rail guides provide a high degree of positioning accuracy, higher than, not only with their counterparts, but even with some optical printers available in the mass market. The classic kinematic scheme allows printing a little slower than the analogs on the

H-Bot and

Core-XY systems, but much more reliably due to the direct drive of the motor along the axes. By the way, along the

Y axis, the printing unit moves due to the movement of two belts (one per rail), but one powerful stepping motor with a through drive.

Along the

Z axis, the heating table moves with the help of two

ball screws installed on the side walls. As guides for the table, there are four cold rolled rollers with a diameter of

16 mm.

Along X and Y axes, block rail guides with integrated belt are installed.

Extruder

In a standard complete set of the printer the double printing block with two extruders is installed. Optionally there is the possibility of installing the third. Extruders are equipped with a gear ratio with a ratio of 1:10.

Pulling mechanism is completely metallic. This allows you to confidently print with any materials, which is also ensured by the limit of heating of the nozzles, right up to 400 ° C. The print unit itself is made according to the classical direct-drive scheme (direct extruder), has a Vulcan-like extruder tube and heating blocks. Cold zone (ColdEnd), forcibly blown by two small fans, the speed of which can be adjusted.

The nozzles with a diameter of 0.4 mm are installed by default. They are interchangeable and, if necessary, you can always install other diameters suitable for your purposes (0.3, 0.5, 0.6, 0.8, 1.0 mm).

In case of a sudden power failure, the printer automatically remembers the current position and saves the print data, lowers the working platform and retracts the nozzle.

The platform of the heating table is made of glass-ceramic. It can heat up to

100 - 110 ° C. This is not so much as, for example, MarkForged printers, but allows you to use any of the most common materials for 3D printing. Adhesive on the platform plays a role similar to the BuildTak surface, confidently holding even very large objects from materials with high shrinkage (for example, ABS).

Calibration screws are located below the heating table.

Control screen

For convenience, the printer is equipped with a

4.3 ” touch screen with an English-language menu. There are separate pre-heat and axle menus. It is quite easy to handle. Intuitive icons allow you to quickly understand the tools and control the printer, almost one-touch.

Interfaces

3D printer

CreatBot D600 is equipped with a USB 1.0 port. This allows you to pair with the computer and send print jobs directly from it. However, we recommend using a USB flash drive slot to the right of the display in order to take full advantage of the capabilities of the device.

Software

The printer comes with free

CreatWare software based on the popular and well-known Cura 1.5.4, which can be downloaded from the manufacturer's website.

It is very simple and easy to learn, so problems in working with this software should not arise.

findings

This 3D printer, created to solve serious problems in printing large models. Workmanship and ease of use allow the CreatBot D600 to be used in professional 3D printing studios, various design and design bureaus 24/7. Build quality 3D printer - factory. All nodes of the 3D printer are made of high quality components. Significant advantages of CreatBot D600 include:

- The possibility of heating the extruder to 400 degrees (Important when 3D printing engineering plastics)

- Reliable and accurate kinematic design for a work area of this size.

- The presence of 2 extruders in the database.

- Factory assembly

If you need a printer with a large print area, we recommend 100% for consideration.

It is possible to order the

CreatBot D600 3D printer in our company. Delivery time 6 weeks.

Equipment catalog with a large print area