This time we received an order for the

manufacture of a mock-up of the aircraft hangar "from scratch", without a real-life prototype or drawings. Therefore, we first solved the design problem, and only then - the production one.

Order and modeling

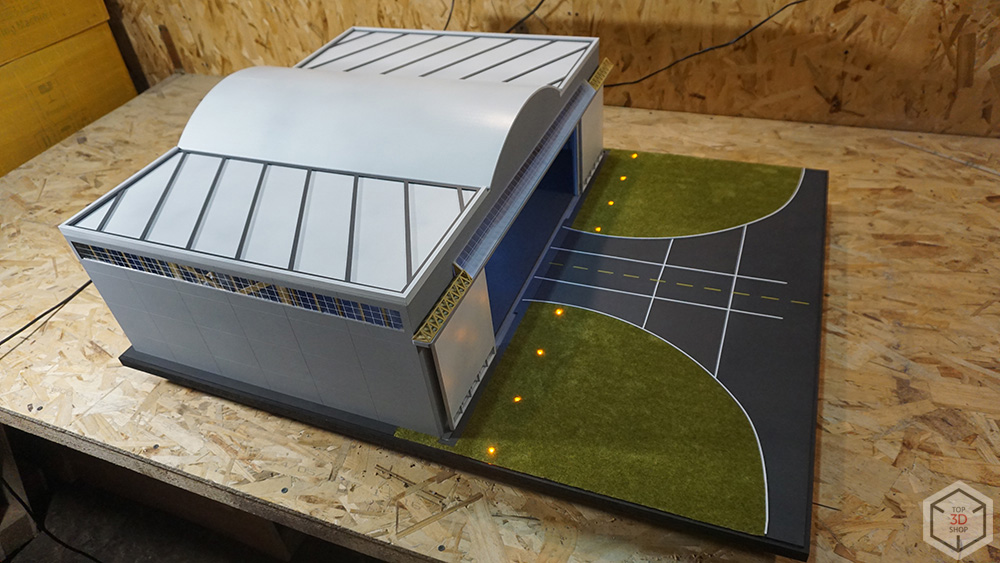

The starting point is a set of photographs of various hangars and a layout of a Boeing 747 liner at a scale of 1: 200. The length is 350 mm, the wingspan is 320. The overall dimensions of the layout, structures with the adjacent territory, should be 1000 x 800 mm.

The hangars in the bulk - prefab frame structures for purely utilitarian purposes, without designer delights. But we needed to make a layout that would not look boring. For this, we had to carefully study the design of existing solutions and connect a little imagination to the process.

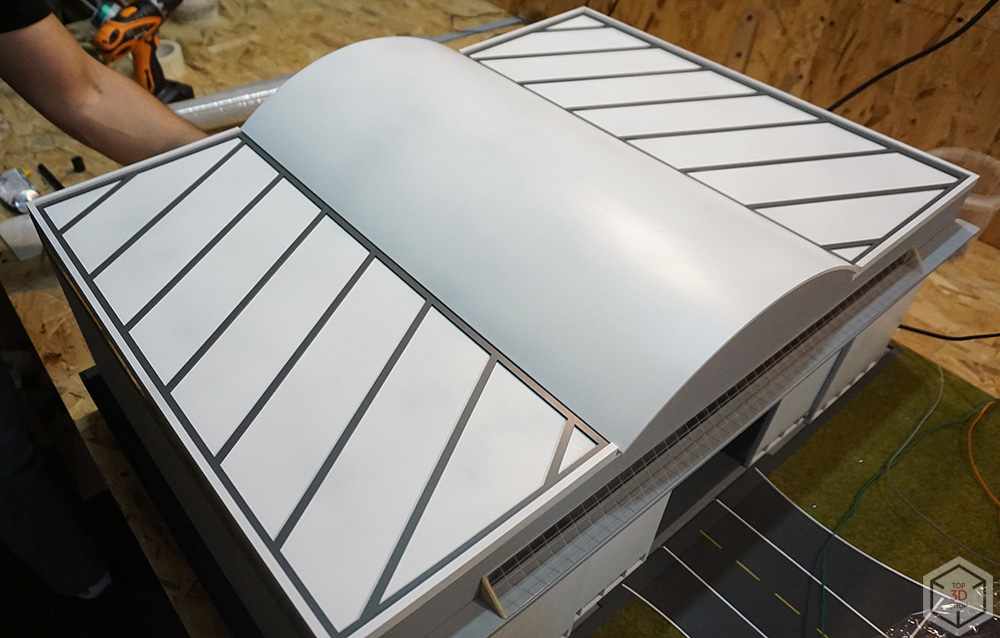

In the original version, the roof of the hangar was completely arched, which is reasonable when building large structures, but visually does not attract attention. In the next iteration of the simulation, taking into account the wishes of the customer, we made a flat roof with a central arched insert. To break the monotonous drawing of the surface, they decided to put a simple geometric pattern on flat segments.

As they did before

Making mock-ups using classical technology is a huge amount of manual labor. The materials commonly used are wood, cardboard, papier-mâché. The process is long and laborious, and the result is costly.

How we do it

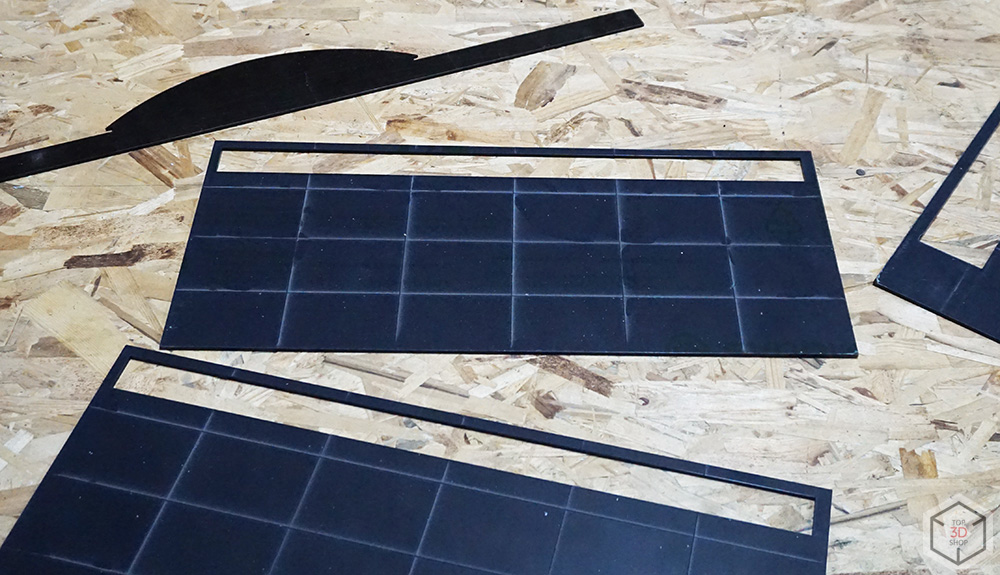

The use of digital models allows you to approve the design before the start of implementation. The use of sheet plastics as the main material and their processing on CNC machines significantly speeds up the process of making a layout, since only painting and assembly is performed manually.

Hangar construction

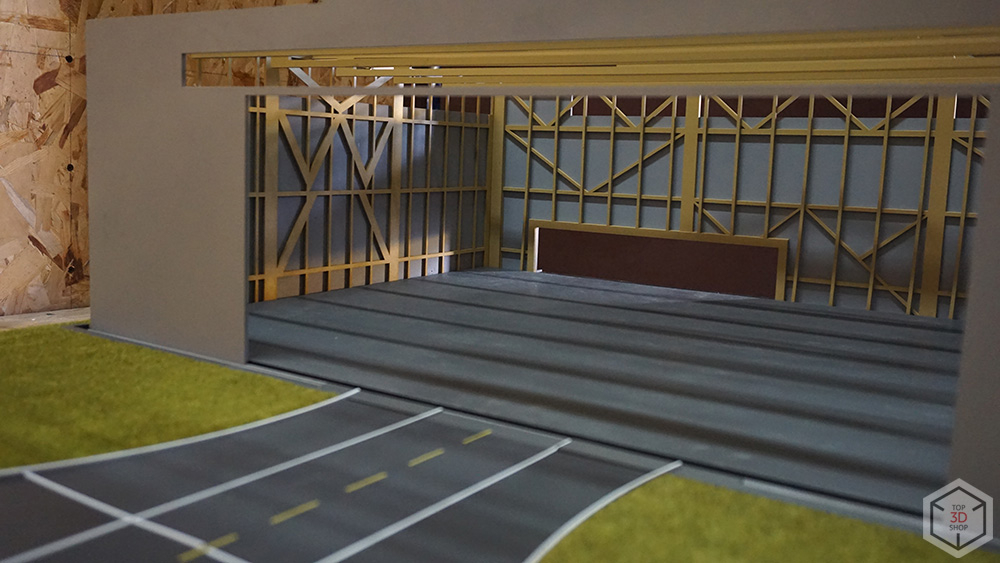

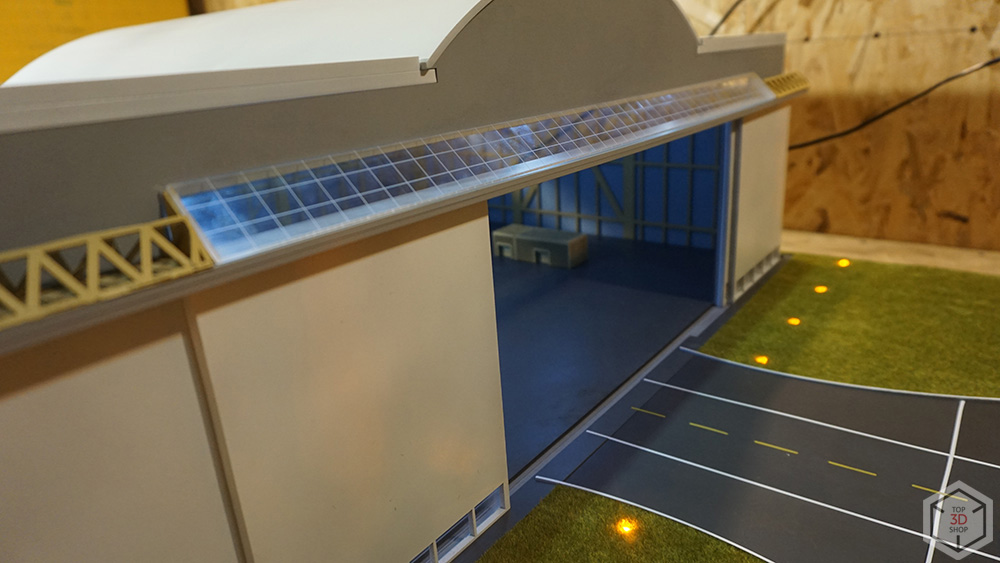

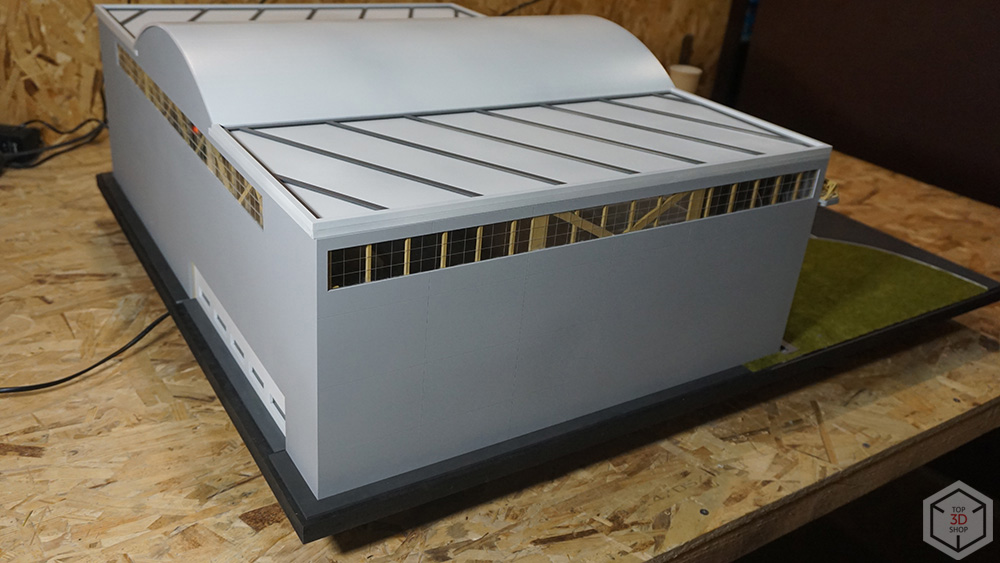

The design is approved, you can begin work on the direct production of the layout. The main building unit is a plate, the outer side of which imitates panels, and on the inside is the frame of the hangar walls. In the upper part of the walls there are slots for glazing.

The frame of the roof is made up of trusses, the elements are attached to the walls. It remains to cover it from above with plates of horizontal parts and an arched middle. Fixed frame of the roof has added us problems with further installation.

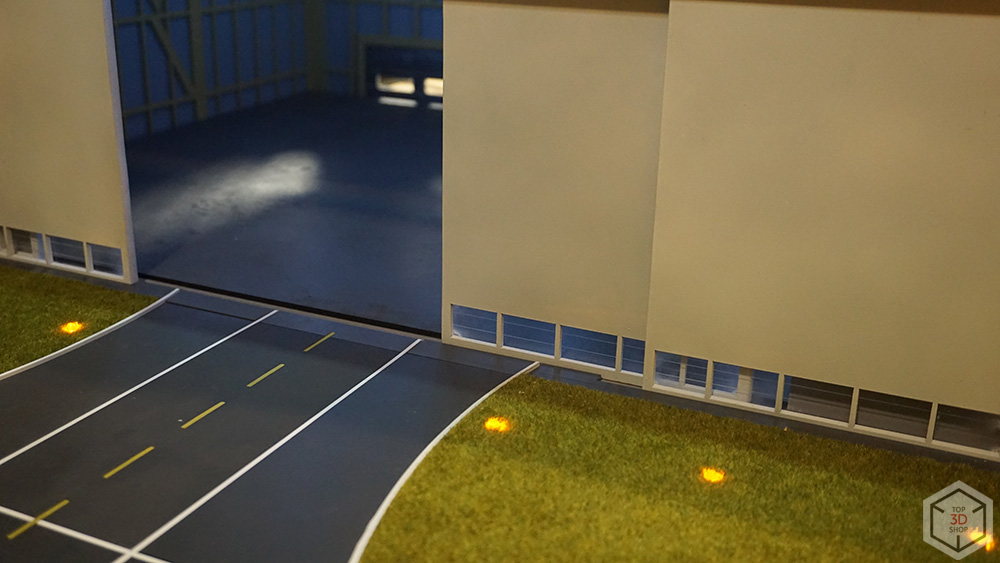

On the roof trusses we placed the LED lamps, repeating the lighting scheme of the real hangars. That's just with the wiring with a partially assembled roof and having problems. With smaller dimensions of the layout, the task would in principle be unsolvable, in such cases it is advisable to make the upper part removable and install an electrician before installing the roof.

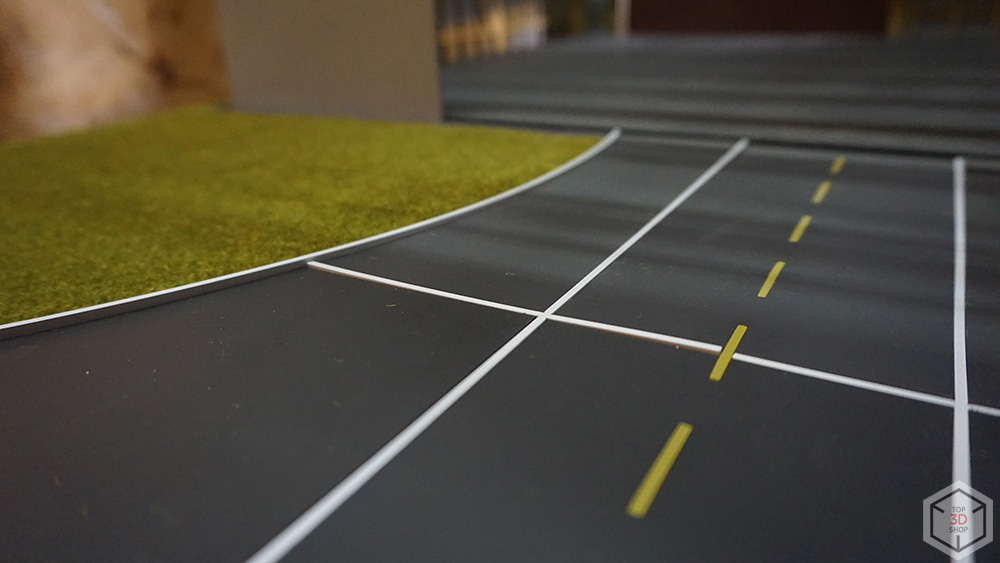

Layout suggests that the aircraft can be placed in a hangar, at the gate, or completely outside. For this, there is a taxiway fragment in front of the gate.

Details turn the box into a mockup

Revitalizes utilitarian design a large number of small things and details. These are the seams of panels and window covers, made by engraving. Embossed taxiway curbs. Metal structures above the doors of sliding gates, small technical buildings.

The floor of the hangar simulates a polymer coating used in real conditions. On the basis of acrylic was applied liquid rubber, as a result, a matte surface was obtained, which by tactile sensations resembled commercial linoleum. The final touch was the installation of LED illumination of the facade of the hangar.

The customer received a nice looking hangar for the aircraft, even if it does not have a real prototype. And we have another successfully solved case for the production of turnkey design models of buildings and structures.

For

making layouts of any complexity and detail, contact

Top 3D Shop . The cost of such an order, depending on the requirements, initial data and terms, starts from 150,000 rubles. If you make

mockups yourself - we are ready to supply you with any equipment required in production:

milling machines, engravers ,

3D printers and

consumables .

Vasily Kiselev,

Top 3D Shop CEO & Founder

Subscribe to the YouTube channel in order not to miss interesting videos on my Instagram , write comments and posts on Facebook .