3D scanning as a factor in industry development

Speech by Maxim Zhuravlev at the Top 3D Expo 2018.

My name is Maxim and I represent the engineering company Top 3D Shop, which organized this event. We supply modern digital equipment such as CNC machines, manipulators, specialized software, 3D printers and 3D scanners. The subject of my report: 3D scanning as a factor in the development of modern industry.

Scanner Types

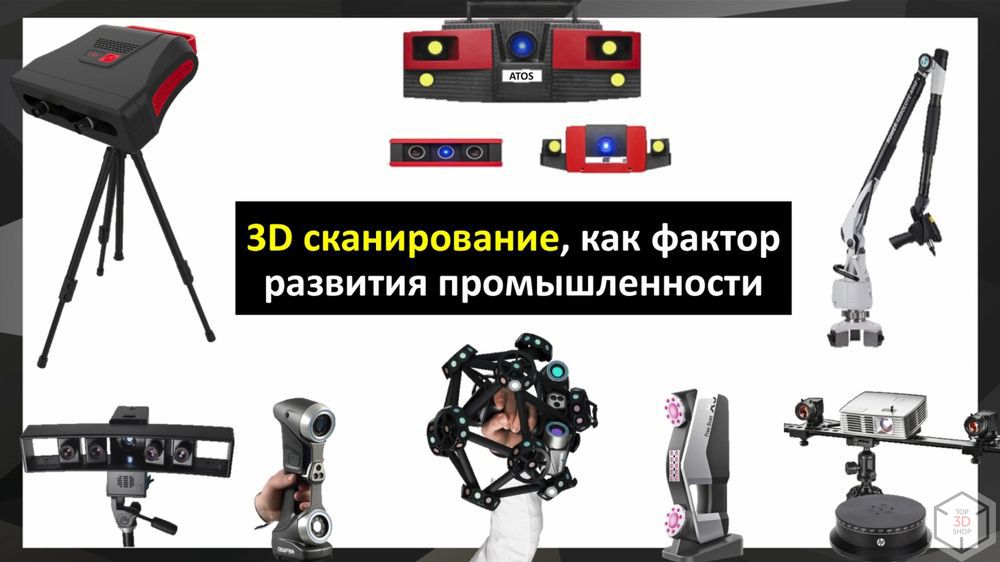

The first slide presents various types of

scanning systems ; they differ in scanning technology, in their type, and perform different types of tasks.

What is very important - a number of scanners have metrological certificates and are included in the State Register of measuring equipment.

Stationary scanners are of different types.

RangeVision , on a tripod, can scan both from a turntable and without it.

The scanner in the middle, from

Solutionix , is a single whole with a turntable, with several degrees of rotation.

On the left we have a

GOM sensor mounted on the manipulator.

Let's take a little look at the scanning systems.

Scanning technology

Scanning systems have different scanning technologies, I selected the most popular ones at the moment: on the right we have the GOM system, it works according to the light structuring technology, where the so-called mask from the projector is projected onto the scanned object, and the deviation is fixed using two cameras.

On the other picture is presented the scanning system Metroscan, working on the technology of laser triangulation. Here the role of the mask is played by a laser beam.

It is important to understand that the scanner is a set of peripheral devices and software produced by the manufacturer. Many 3D scanners differ most noticeably precisely in terms of software, for example, on the basis of model stitching. These methods vary: some use cross-linking on geometry, others on texture, and others on labels or a combination of these methods.

I identified several types, from right to left: stationary scanners, with their help we scan relatively small objects with greater accuracy than other types of scanners are capable of.

Ground-based laser scanners are designed to scan large objects, it can be a whole building or elements of an industrial facility.

Mobile measuring machines, with the possibility of replacing the scanning head on the probe. And handheld scanners, the most mobile and also quite accurate.

Scanning systems not only make it possible to produce better products, but they themselves are getting better. This slide shows the

Artec handheld scanner -

Artec Leo . This is one of the most interesting scanners on the market, its distinguishing feature is the ability to scan and work with scan results without connecting to a workstation and power supply, for this it is equipped with a battery, a good processor and an integrated touch screen.

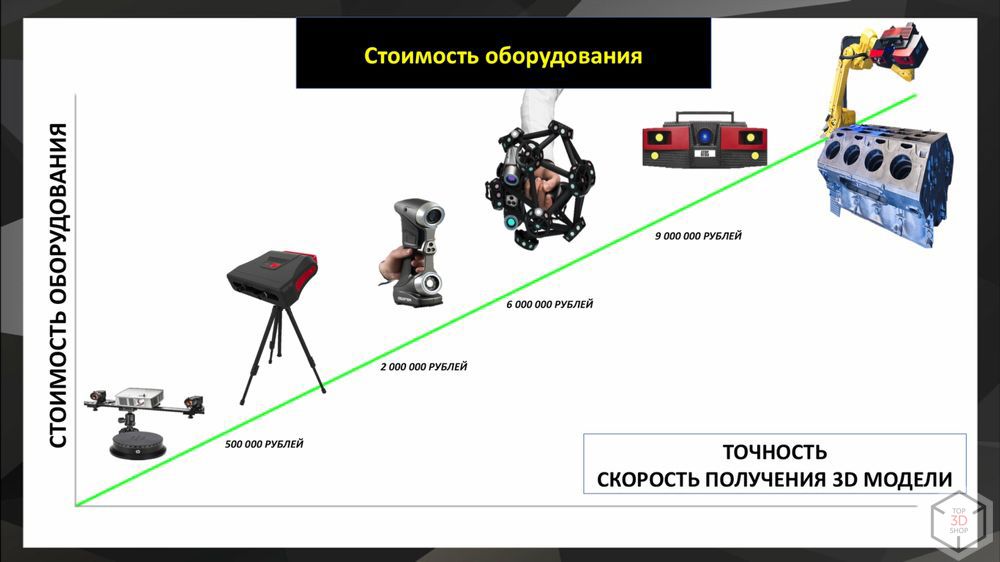

Cost of equipment

Different types and price categories of scanners have different accuracy. it depends on the technologies used, and on the design decisions of the scanner creators.

Scan tasks

One of the main tasks of 3D scanning in production is reverse engineering or reverse engineering. Obtaining the drawings of the unified design documentation is one of the problems that are solved in modern production using scanning. In the case when there is no scanner, the process of obtaining a drawing looks like this: engineers go to an object with a different measuring tool to remove the sketched dimensions, measure, return to their workplaces and begin to design the model from scratch, as shown in the

CAD program - AutoCAD,

Compass , SolidWorks or some other, which is in the enterprise.

Modeling is a time-consuming task that can take a lot of time from the designer. Another negative factor in the process of creating a drawing can be a mistake of resizing, in this case, a group of engineers have to return to the object.

This procedure can be repeated several times until a high-quality product drawing and a 3D model we need are obtained; this can be time-consuming. Any modern production works with 3D-models, wherever you turn now to create a prototype or to obtain a final product, such as a mold, a 3D-model will be required everywhere.

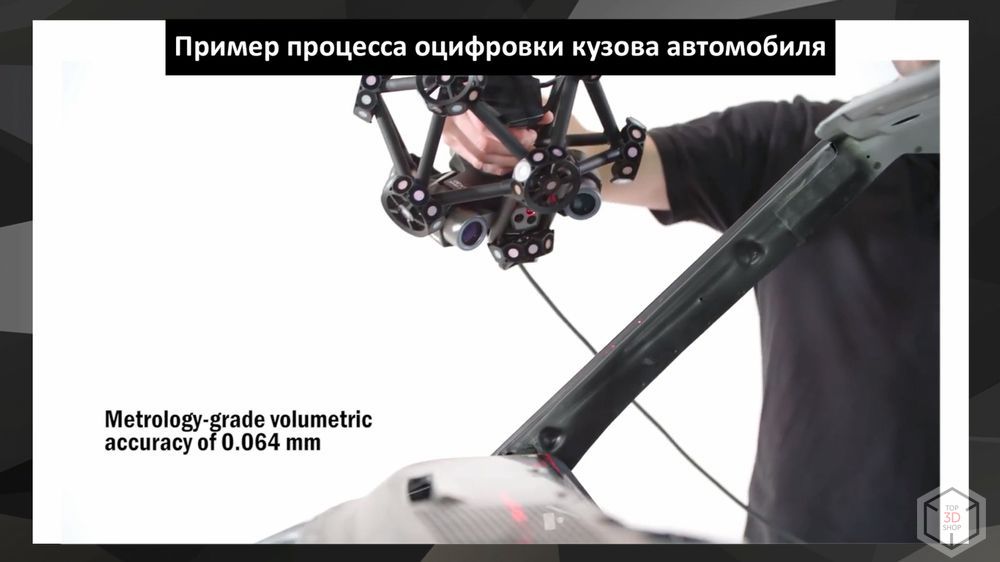

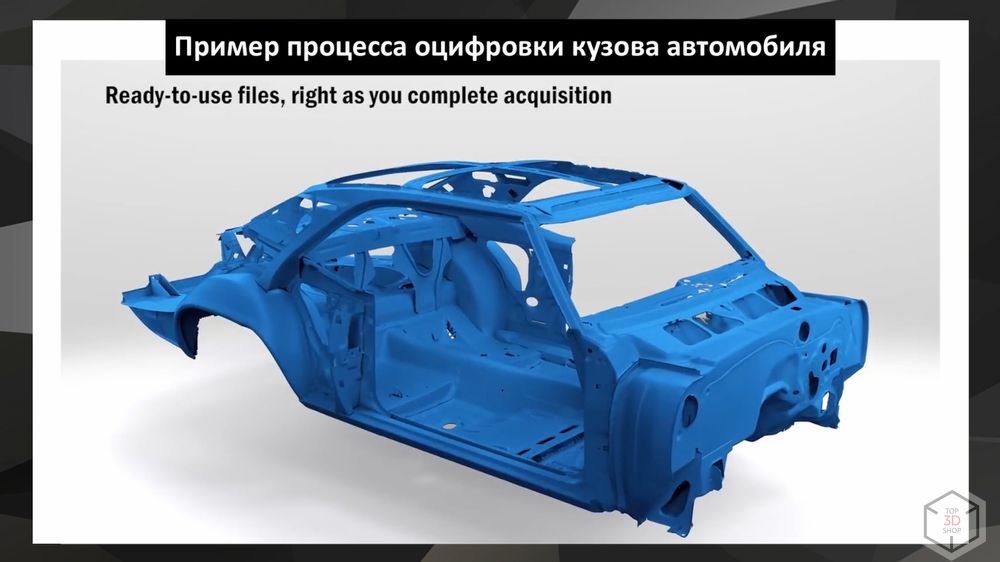

Here you can observe the process of digitizing the car body - a non-contact method, as you see.

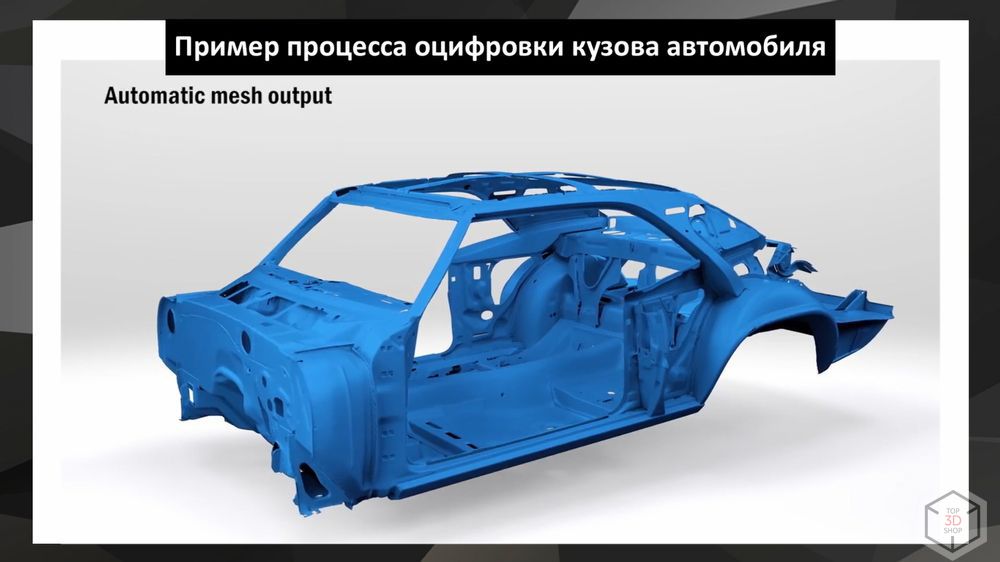

The scanning system receives a three-dimensional model in the form of a cloud of points; then, using software, we obtain a 3D model in the .STL or .OBJ format.

Further, from this model we can obtain design documentation, remove the required dimensions. As you understand, if a person did it manually, he would spend an enormous amount of time. The digitization process is quite simple; even a schoolboy can handle it.

The video shows

Metrascan scanning system from the company

reaform , the advantage of which is that the system allows you to scan with a volumetric accuracy of 60 microns per 16 cubic meters.

Please pay attention immediately - volumetric accuracy and linear accuracy are different parameters, they should not be confused.

Diagnostics

When scanning, we obtain the geometry of the product along its entire length, and having specialized software, we can make a conclusion about the object being scanned, without returning to workplaces, we can immediately send a report to the production site, where necessary measures will be taken to prevent accidents and troubleshoot - this will save the budget from large losses.

Information will be recorded on the hard disk and unloaded into circulation. That way you will always have access to it.

Manual sizing is acceptable only for large heavy objects of not the most complex geometric shape. By the way, we also digitize large objects using a scanner, for example, at home or industrial installations. These tasks are usually performed by specialized scanners.

But, as we know, most of the real tasks in production are different.

Real production tasks

On this slide you can see examples of real-world problems of modern production, where it may be necessary to obtain a digital model of an engine head, press mold or other product of complex geometric shape, which is almost impossible for a person to do manually.

Modeling

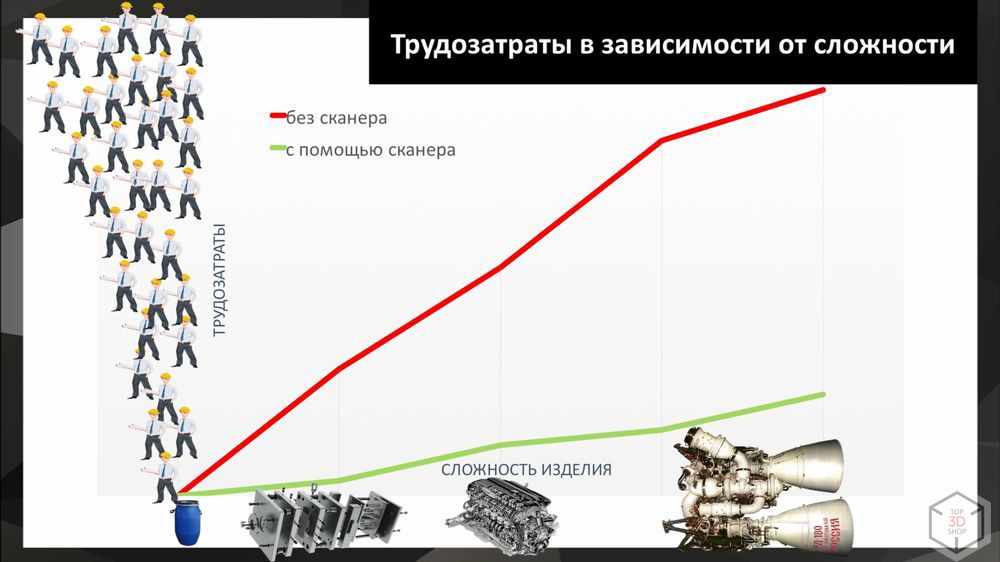

On this graph, you can observe the dependence of labor costs for obtaining a 3D model and design documentation for a product on its complexity. As you understand, a scanner doesn’t care what it does: a ball, a cylinder, an engine completely or unassembled.

Manufactures where there are no scanning systems that still use human labor to obtain design documentation, drawings, use human resources inefficiently and are deprived of the opportunity to increase their profits, reducing labor costs in the field of design and directing them to other necessary tasks.

Control

Another area of application where scanning systems are indispensable is the implementation of control. On any production there is a control: input, output, intermediate. We can use various tools in controlling, I will not talk about control methods that are outdated and no longer effective. In most cases, where there are no scanning systems, measuring and measuring machines are used, if we are talking about modern production, otherwise, these are different sorts of templates and visual controls, we will not talk about that.

We live in an era when one product replaces another with ever faster, rapidly changing products make it necessary to change the development cycle, to make it as short as possible, and with it the requirements for controlling the output. If you look at the products 5-10 years old, you will see that the variability looked quite different. Technological progress of production, changes in the technology itself, and accelerates the rate of change in products.

Receipt of new products in a shorter period of time forces to change the production technology and related control. Tougher requirements for the quality of products also change the requirements for quality control, which is natural. Increasing control allows to produce more and more high-quality products, at a new level inaccessible to enterprises that ignore the progress of quality control tools, and set trends in the development of entire industries.

Benefits of 3D scanning

The main advantage of scanning systems over other methods of control: full scanning of product geometry along the entire length without CAD data,

inspection of the entire surface of products and functional sizes, export of measurement results and reports to internal servers and databases, statistical process control.

As has been said many times, the ease of learning is important here. For example, I scanned without learning: I took out a scanner, installed software, scanned the product right in our office and received a 3D model.

Quite a significant factor is the fact that scanning systems are mobile, unlike the same traditional measuring and measuring machines, allow you to carry them with you and digitize dimensional objects, scanning them in parts and stitching a model in software.

An important factor is also the fact that when you have a scanner, after receiving 3D models of several parts, you can carry out a virtual assembly of the product before launching the assembly at a production site, see all the problem areas and fix the shortcomings without losing too much time.

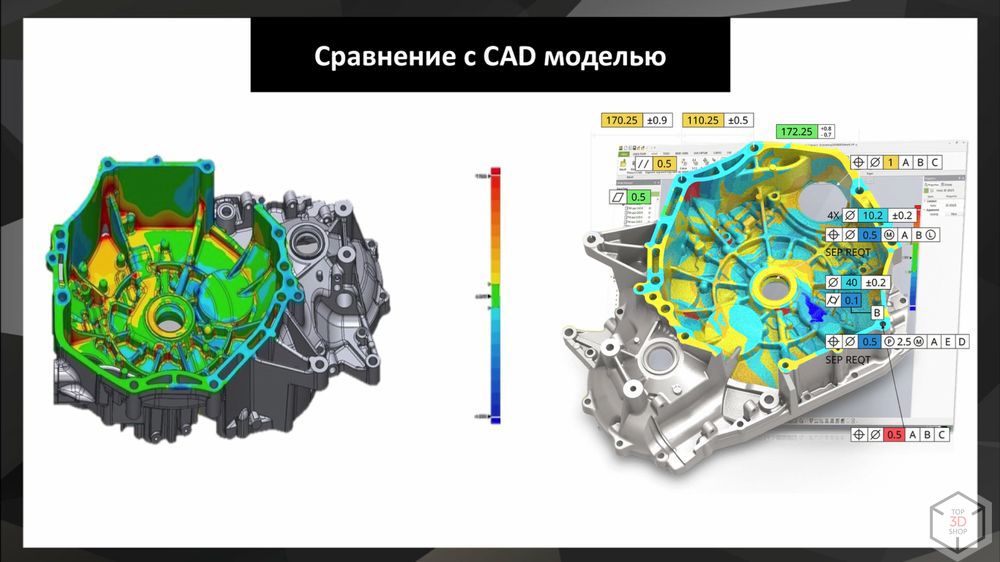

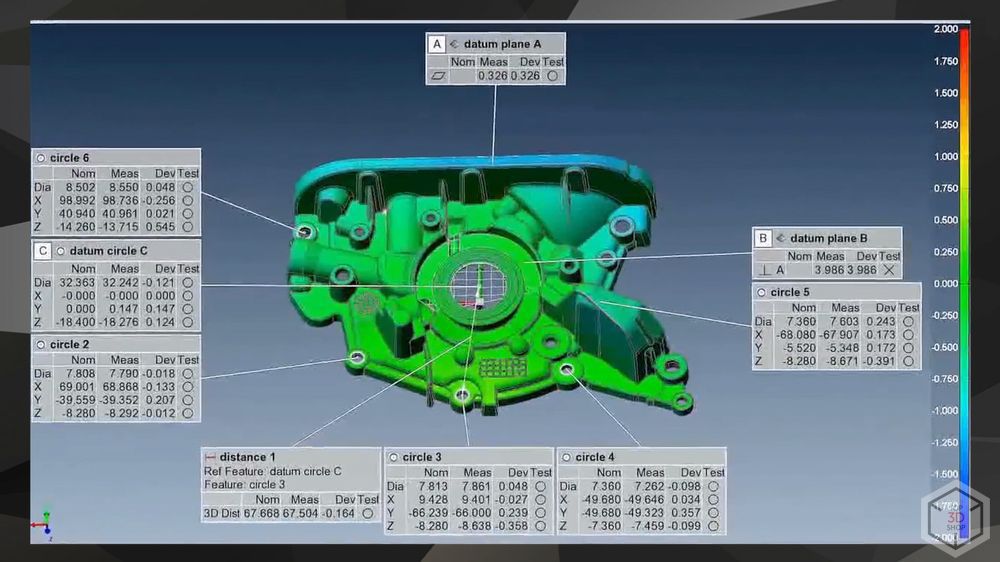

On this slide, you can visually see a comparison of the scan result with the CAD model, all deviations are expressed as a temperature scale, where the green zone is everything that is within tolerances, the red and blue ones are outside of it. You can make a comparison in automatic mode. The software has the ability to fine tune to display the report in the form of an Excel spreadsheet or PDF. The result can be directed to the production, technologist, for the early elimination of the marriage.

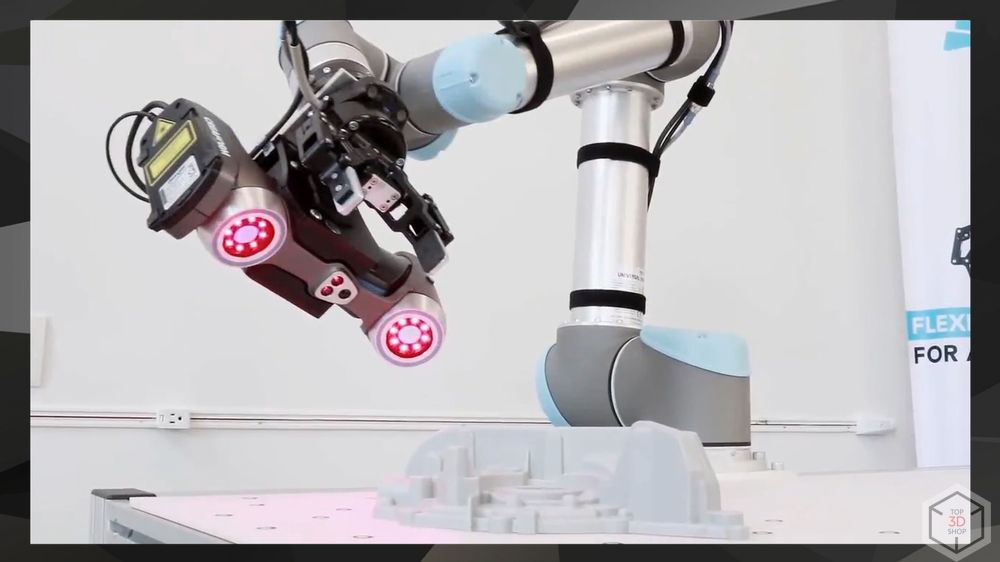

Having a scanner in production, you get the opportunity to automate the process of monitoring with the help of manipulators.

Here you see an inexpensive solution, about 5000,000 rubles, which is easy to integrate into the technical chain. This will allow to control all products and create a digital library of products of your production. When an end user detects a marriage, you will be able to find the cause of the marriage by retrieving a 3D model from the library.

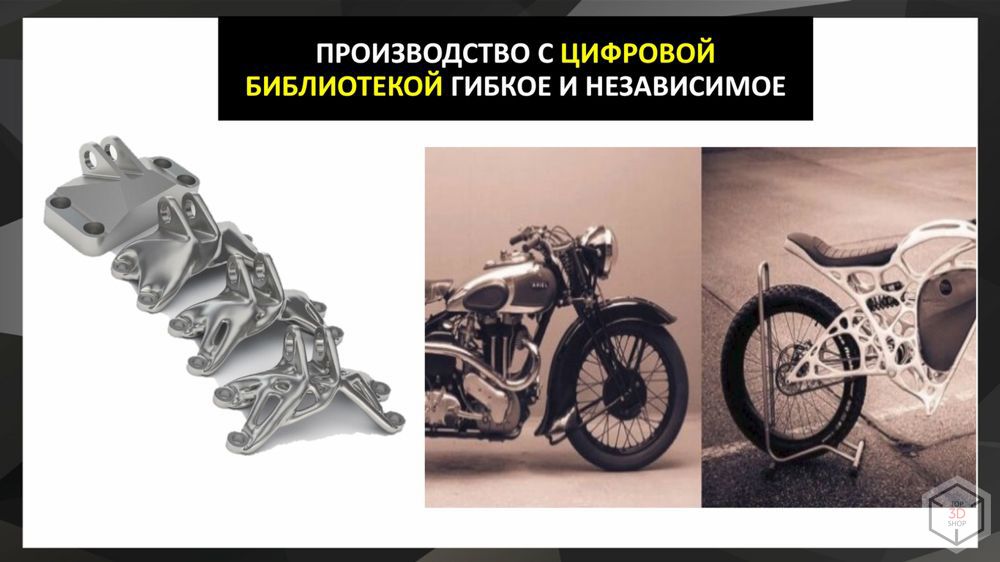

Digital Libraries

Production with a digital library is more flexible and independent. Imagine that you can influence every product that you don’t even see, making them better and better, changing their appearance, making them easier, without losing the strength characteristics and the necessary functionality, reducing the amount of raw materials used, thereby reducing production costs.

And so - with every detail. With all the products. This, together, helps to improve the quality of all your products, making it unbearable for competitors.

Such production is less dependent on the supplier and, in the event of supply disruption, may in the shortest time possible optimize the process for a new raw material from another supplier.

Everything goes to the fact that such automation will be in all enterprises, without this they simply will not stand the competition.

Unlike control measuring machines, scanners do not require alignment of the details and writing a complex control program for each product, which not every qualified specialist can handle.

To work with a scanner, it will be enough to train two people. This may be the chief engineer, a specialist in charge of production, the designer. When you dismiss or transfer such a specialist, it will be possible to train a new employee fairly quickly. Of course, you need both skill and software knowledge, all this comes with time, but an employee can start and start working in just a couple of days.

By storing all the information about the objects scanned at the production site, you can form a picture of the products produced and, based on this, predict the further production cycle and influence it to reduce costs, if we are talking about product quality control, and prevent accidents, if we are talking about diagnostic scanning. equipment. Production will stop, the instrument will break, deadlines will be broken and contracts will be disrupted, as a result you will lose the trust of your customers, who next time will turn not to your company, but to another. All this can be avoided, as you already understood, by timely upgrading of controls.

Why it is worth contacting when choosing equipment to us

We are a multi-brand company and do not give preference to equipment of a certain brand, selecting it in accordance only with the requirements and needs of the client. At the same time, we have established contacts with manufacturers and enough experience to competently understand the properties of the equipment and make a reasonable choice.

Turning to the

Top 3D Shop with its goals and objectives, the buyer can be sure that he will be given the option most suitable for achieving these goals and solving problems, and not the most beneficial to any one manufacturer or distributor.

Working with us, you will save your time, and as a result, you will save money and spend the modernization of production quickly and without unnecessary headaches.

Vasily Kiselev, Top 3D Shop CEO & Founder

Subscribe to the YouTube

channel in order not to miss interesting videos on my

Instagram , write comments and posts on

Facebook .

For the introduction of Digital Production technologies in your company, please contact

us :

Email: sales@top3dshop.ru

Telephone: 8 (499) 322-23-19