In the 21st century, when computer technologies are ever more closely intertwined with human life, the use of 3D printing has ceased to be something supernatural and quite organically entered everyday life.

It is quite expected that 3D printing has found its application in medicine as well: in dentistry, in the manufacture of implants, in the creation of models for preoperative planning, in the creation of artificial bones, tissues and blood vessels.

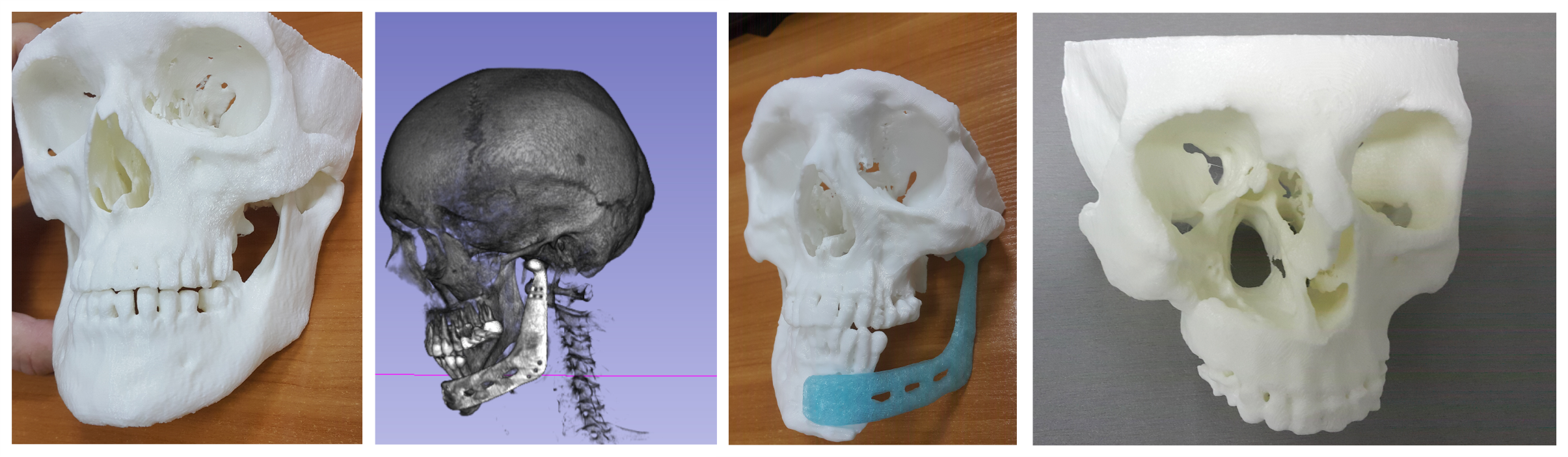

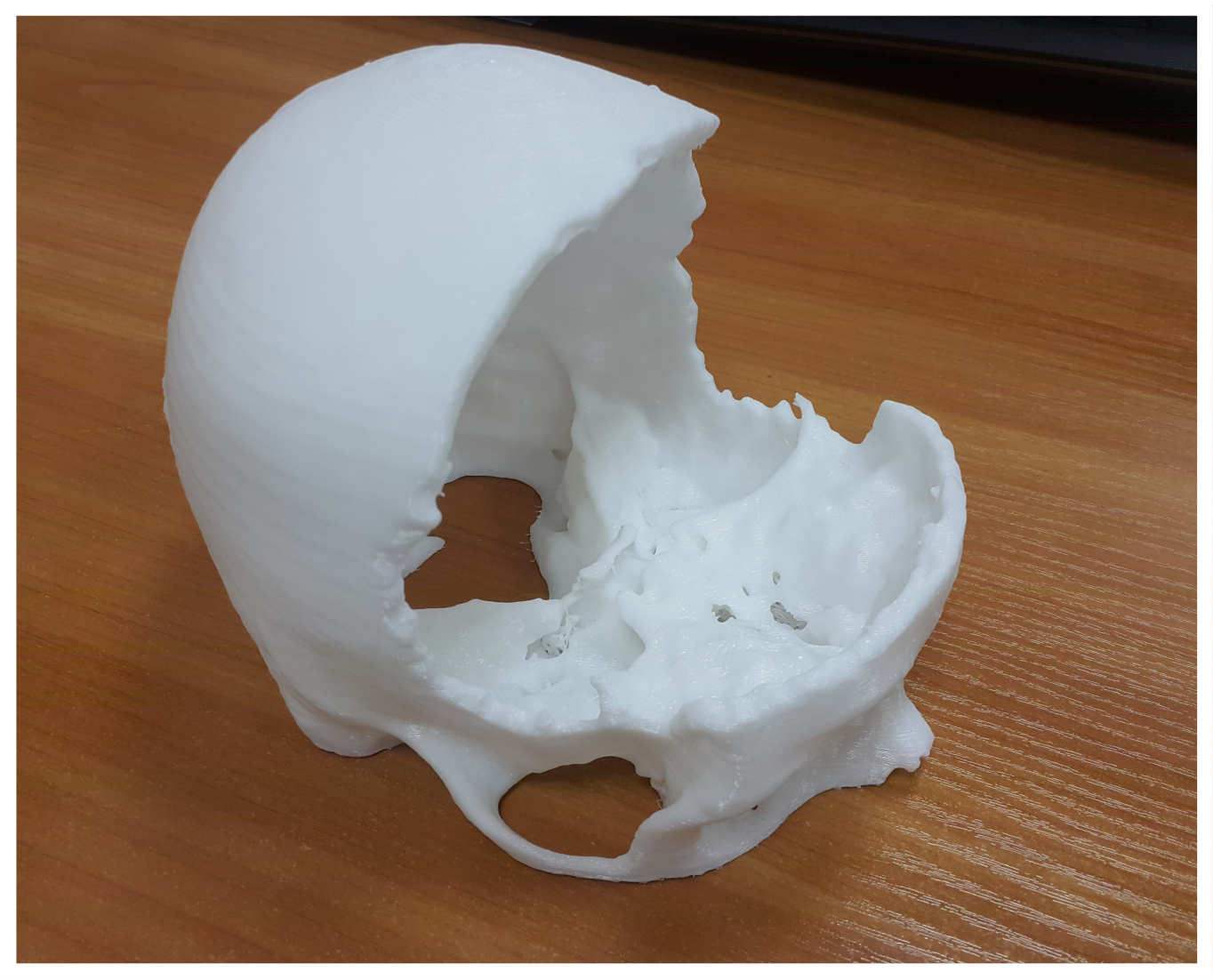

The volumetric 3D model makes it possible to visually present the scale of the work to be carried out, to take into account the individual characteristics of the patient, to identify defects that are often overlooked in conventional images. Based on the printed samples, careful planning of the operation takes place, all possible risks are calculated, suitable implants are created.

Evgeny Grigoriev from the Tomsk Research Institute of Oncology decided to use additive technologies in medicine and create three-dimensional models for use in his professional practice and the practice of his colleagues.

As Eugene says: “The interest in 3d-printing appeared more than two years ago. Initially it was a hobby, then having studied the issue in more detail, I began to reflect on the possibility of using printing in medical practice, read various forums, studied 3d-modeling programs that could translate the DICOM medical format into a convenient file for 3d-printing. After weighing all the pros and cons, I decided to try new technologies for me, but since it was more of an experiment, my first work was published by Tomsk guys from Bestfilament. Having seen the final result, having asked Best'a colleagues about the technology of printing, I decided to use additive technologies in my practice. ”

To date, Eugene has his own method of manufacturing 3d-models, based on the integrated processing of the received medical images and consists of several stages:

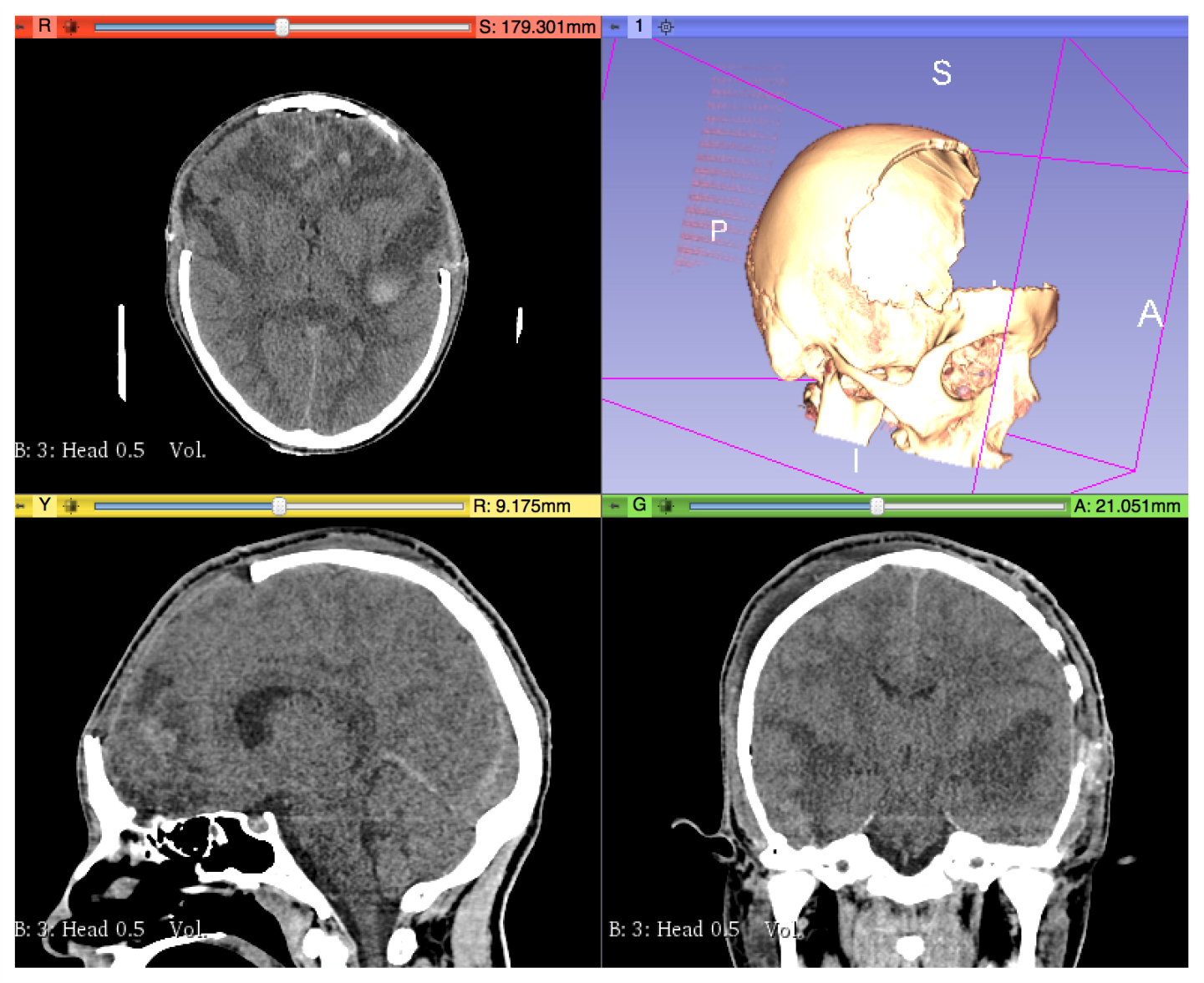

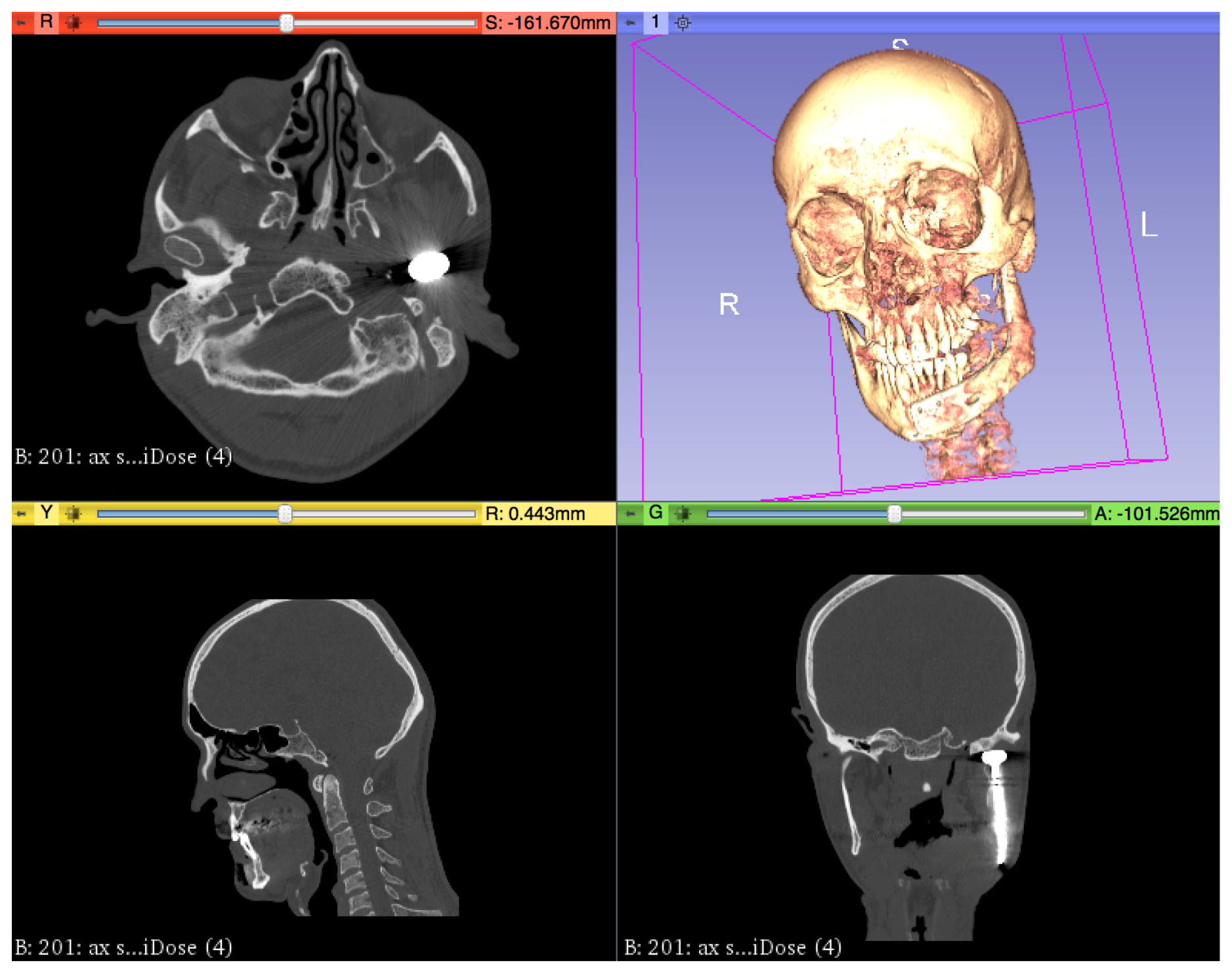

The first stage : a computed tomographic study. The resulting scans have a standard DICOM medical format, and these files are suitable for the next stage.

The second stage: the

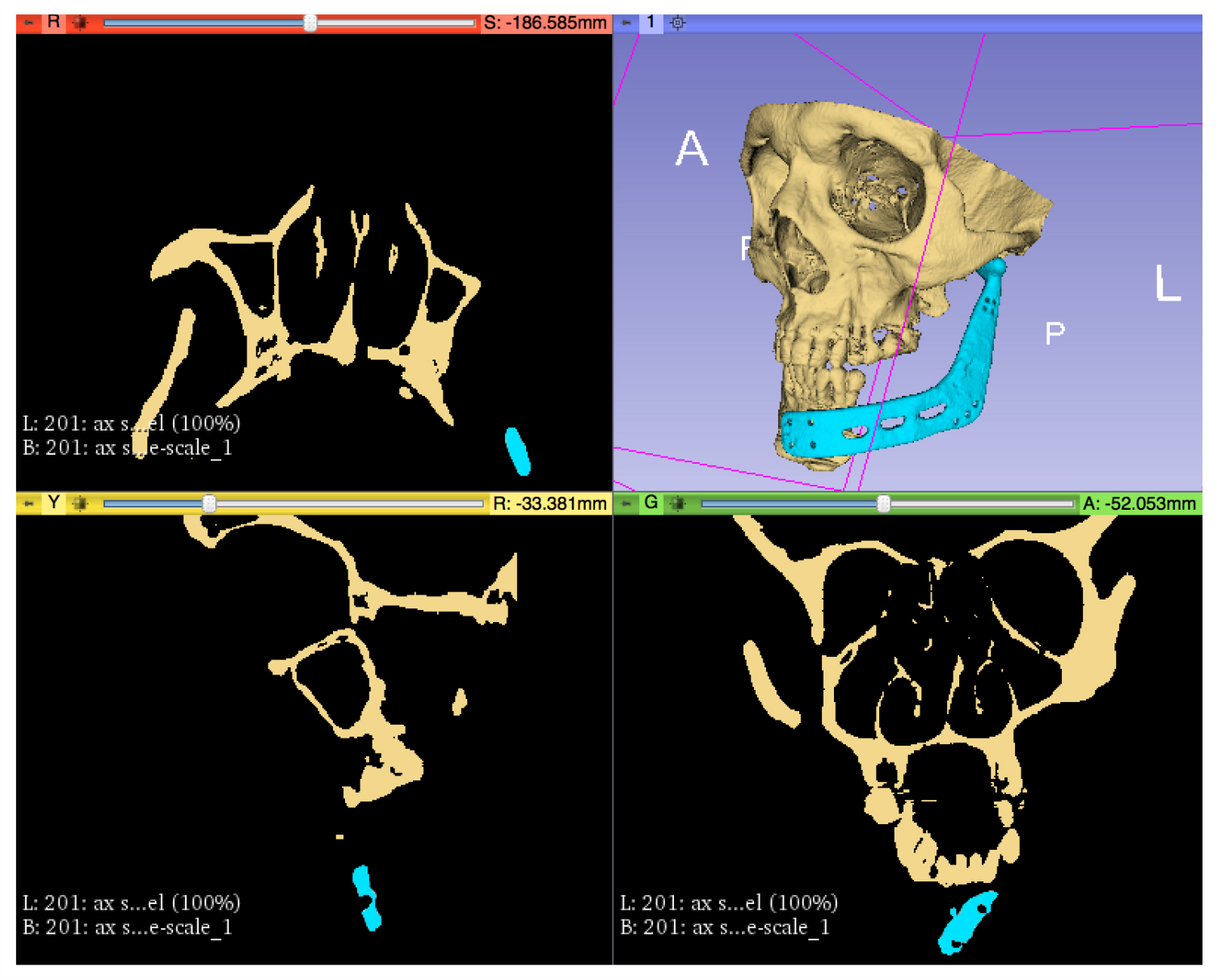

The second stage: the creation of a virtual model. At this stage of operation, the DICOM medical format using additional software packages is converted to a surface file .stl, obj, or other options that the slicer can interpret. In our case, we used the open-source 3Dslicer software package (3dslicer.org), in which the model is prepared in several steps: trimming with the “zone of interest” restriction, which is directly subject to 3D printing; removal of artifacts from metal (implants, pins, etc); sampling of the density range included in the layout of the "surface"; use of tools for smoothing and removing "noise". The result of the manipulations is a virtual model of the zone of interest as a file with the resolution of .stl.

The third stage: the preparation of a virtual model for printing. The .stl file is loaded into the slicer program, the main task of which is to prepare the model for printing on a specific 3D printer model.

The final stage: printing the model, after which the finished sample is studied and the optimal treatment method is selected.

“Over the past two years, I have had to apply 3D printing technologies in such areas as: neurosurgery, maxillofacial surgery, oncological practice.

In neurosurgery 3d-printing is actively used in the recovery of postoperative defects. Here the 3d model plays the role of a matrix, on the basis of which an individual prosthesis is reproduced.

In oncology practice, using 3d-printing, visualization of defects in the framework of destruction occurs. In oncological diseases, bone tissue is also affected, for example, the facial skeleton. This may be a defect in the lower wall of the orbit or the upper or lower jaw. Naturally, after removal of the mass formation, this defect should be repaid. This is where 3d printing comes to the rescue. In the presence of a 3d-model, the surgeon has the opportunity to familiarize himself with the upcoming area of work before the operation: hold the model in his hands, view it from different angles. Prostheses are also created on the basis of such models, which, of course, plays its positive role on the aesthetic result of the operation.

From recent I can cite such a case of “joint work” of a 3D printer and surgeons. My colleagues from the maxillofacial department were approached by a patient with a diagnosis of hypognath

(note ed., A dental phenomenon in which one can see insufficient development of the upper jaw). In this case, I printed a model for matching the upper and lower jaws. The 3D model made it possible to move the lower jaw back and forth, turn it around and plan the course of the operation. As I found out, the operation was successful, the defect was corrected, the patient was happy.

In conclusion, I would say that for me the significant advantage of using 3d-printing is the ability to create low-cost volumetric models in a relatively short period of time. As a result, having a high-quality 3d model of the upcoming work area, the specialist carefully studies the defect and plans the course of the future operation, which minimizes the likelihood of complications and reduces the time of the operation. ”

I would like to finish this article with the words of the Roman philosopher Seneca:

"The time will come when our descendants will be surprised that we did not know such obvious things."

And indeed, some twenty years ago, quite a small part knew about the possibilities of 3D printing, but now the time has come when anyone can purchase a 3D printer.

I wonder what the future holds for us?