Hello! This is an overview of the available photopolymers for stereolithography 3D printing. Stereolithography, as compared with FDM, gives far greater accuracy and better surface quality, but stereolithographic 3D printers themselves and the materials for them were, until recently, prohibitively expensive. The situation has changed with the appearance on the market of

Wanhao Duplicator 7 , the most inexpensive photopolymernik. Along with the growth of its popularity, the demand for inexpensive photopolymer resins also increased. Here we look at several samples of such materials.

We decided to compare the three brands of low-cost stereolithography resins: Fun To Do, Harz Labs and UV Res. Prices in the article are indicative and subject to change.

A parameter that we will not indicate in the characteristics, since these polymers have the same one — the wavelength at which polymerization occurs — the generally accepted and most common 405 nanometers.

Fun to do

Fun To Do is a Dutch-made photopolymer resin that is already quite popular among fans of 3D printing. It is an inexpensive and high-quality product that can be used with the vast majority of stereolithographic printers. Three materials of this series came to us for review: Standard Blend - for prototyping and decoration, Industrial Blend - for functional parts and Castable Blend - burnable polymer for casting.

Specifications:Capacity, l: 1

Printing technology: DLP / LCD / SLA

Manufacturer: Fun To Do

Shore hardness, D: 35

Country of origin: Netherlands

Price, rub: 4,900

Fun To Do Standard Blend is perfect for budget 3D printing for various purposes. The resin has a high polymerization rate. The material is compatible with almost all stereolithographic 3D-printers. The minimum layer thickness is 20 microns.

The polymer comes in three colors - red, natural and black.

The parameters of the Fun To Do Standard Blend flash on Flashforge Hunter, and we printed it on it:

Layer s: 2

The first layer, with: 10

Layer thickness, mm: 0.05

Printed products to the touch rubber-like, but fragile. Due to this, the support is very easy to break off without causing damage to the model itself. After the final illumination, “baking” of the finished model, the polymer becomes solid.

If it is bad to shake up the black polymer before pouring it into the printer, the products are greenish. This effect was found near the end of the bottle. Obviously, the polymer should be shaken before each use. However, like any other.

If the polymer is left for two weeks in the printer, the pigment will completely settle to the bottom. In general, of course, it is better not to leave any polymer for two weeks in the capacity of the printer. But, here we also have this experience.

The polymer does not stick to the Fep-film, which pleased, and quite easily washed off, the model is easily removed from the construction platform.

Specifications:Capacity, l: 1

Printing technology: DLP / LCD / SLA

Manufacturer: Fun To Do

Color: Natural

Shore hardness, D: 75

Country of origin: Netherlands

Price, rub: 5900

Fun To Do Industrial Blend is a high-strength industrial photopolymer with a wide temperature range. The parts printed by him do not lose their properties at temperatures from -45 ° C to + 225 ° C. Used, among other things, to create master models and molds for working with silicone. Available in the same colors - red, black and natural.

Flashforge Hunter's flash options:

Layer, with: 1,5

The first layer, with: 12

Layer thickness, mm: 0.05

The polymer initially has a high rigidity and requires the mandatory “baking” of products with a UV lamp or intense sunlight - without this they can crack and bend. Polymerized qualitatively and accurately, the models look no different from Standard and Castable.

Specifications:Capacity, l: 1

Printing technology: DLP / LCD / SLA

Manufacturer: Fun To Do

Color: Red

Shore hardness, D: 73

Country of origin: Netherlands

Price, rub: 5900

Fun To Do Castable Blend is used to print casting models used in casting from various metals, including noble ones. Excellent support in jewelry, in the manufacture of works of art, toys or utilitarian metal products. The polymer gives high detail and has a low ash content.

There are no specific requirements for working with Fun To Do Castable Blend. The main difference is the longest, among the Fun To Do polymers, flare.

Flashforge Hunter's flash options:

Layer s: 2

The first layer, with: 15

Layer thickness, mm: 0.05

All three types of Fun To Do polymers are characterized by high accuracy, hardness (after “baking”), high polymerization rate, pleasant and bright colors.

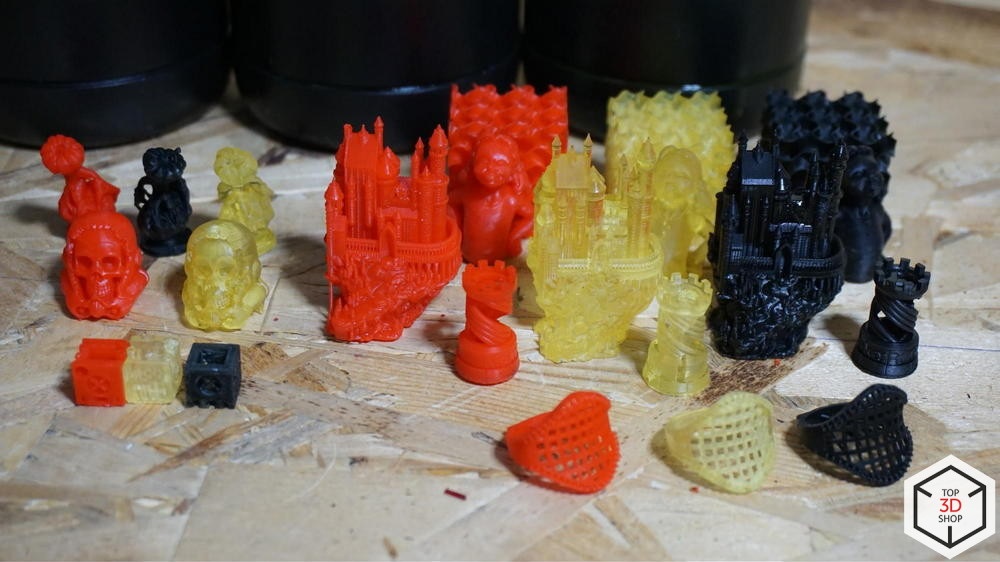

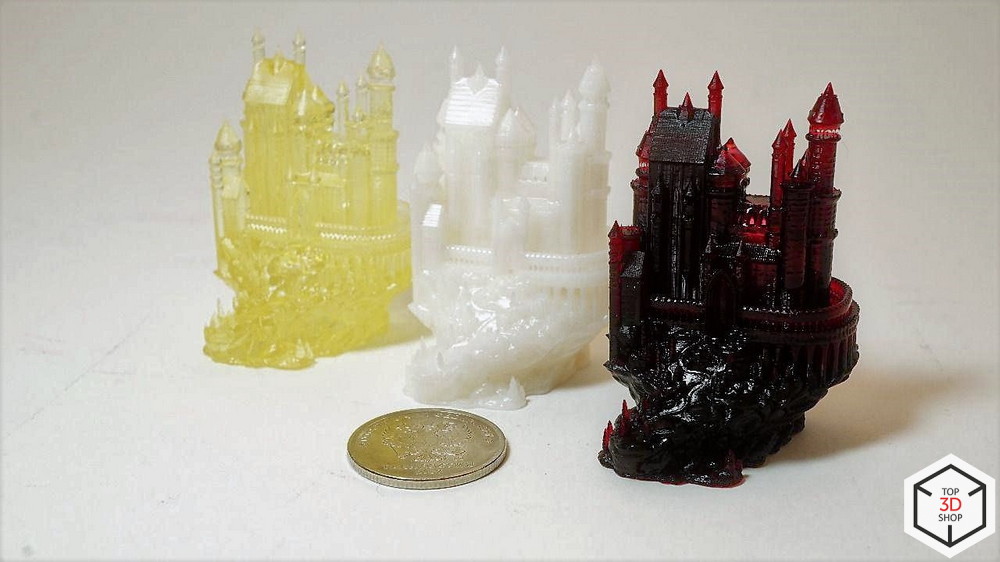

The photo shows Catable (red polymer), Standard (black) and Industrial (yellow polymer).

Shrinkage - within the standards stated by the manufacturer.

Models with a complex structure are obtained well.

Very neat figures.

We used such cubes to measure deviations in size.

Everything is within normal limits.

UV Res

UV Res is a

Russian- made photopolymer. We continue successful import substitution!

On tests, we had two polymers from this manufacturer, as read below.

The company also produces an initiator for polymers, significantly accelerating the time of polymerization - by 40-50%, with the addition of about 1% by weight of the polymer.

It is available on pre-order, the estimated price for a package of 5g -

2690 rubles.

Pigment paste for dyeing polymer is produced in a package of 10g, the estimated cost is

1090 rubles per package. Also available on pre-order.

Specifications:Capacity, l: 1

Printing technology: DLP / LCD / SLA

Shore hardness, D: 55-60

Country of origin: Russia

Price: pre-order, about 10 990 rubles.

The photopolymer of domestic production UV Res M001 is designed for printing models for various purposes. Retains the perfect balance of stiffness and functionality in finished products. Suitable for printing master models. Keeps durability and hardness at a temperature up to 120 degrees Celsius.

One of the most accurate polymers that were on the tests.

Differences from Fun To Do - sticks to the film, you have to use a spatula to drain the polymer from the bath. Medium density. Available in one color.

Flashforge Hunter's flash options:

Layer s: 5

The first layer, with: 20

Layer thickness, mm: 0.05

Specifications:Capacity, l: 1

Printing technology: DLP / LCD / SLA

Shore hardness, D: 75-80

Country of origin: Russia

Price: on pre-order, about 12,290 rubles.

Difference from polymer M001 - products from M111 are capable of maintaining strength and rigidity at temperatures up to 200 degrees. Less accurate and slower.

Flashforge Hunter's flash options:

Layer s: 8

The first layer, with: 30

Layer thickness, mm: 0.05

Harz labs

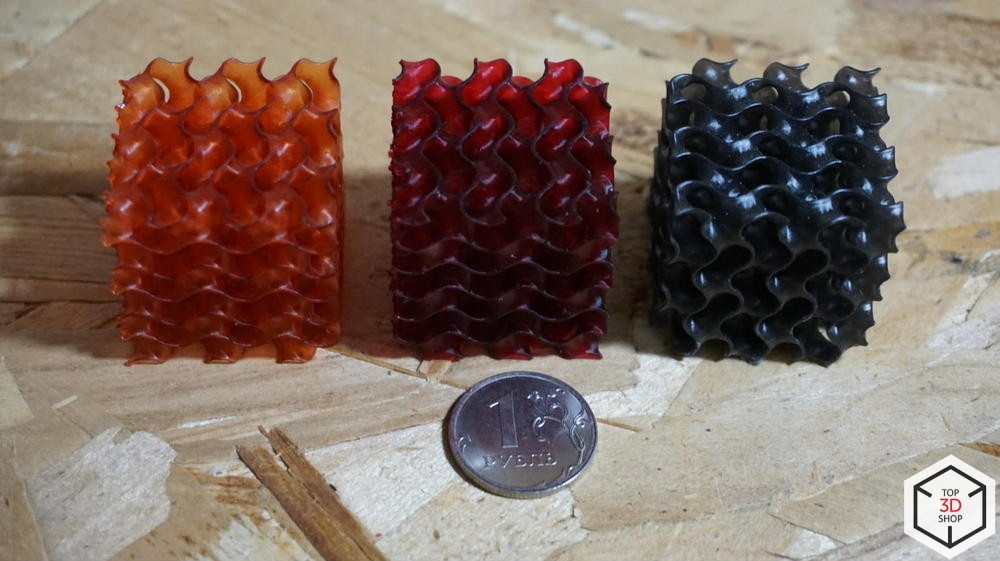

Harz Labs polymers on tests were represented by one name - HARZ Labs Model, but in three colors: Red, Cherry and Black.

Specifications:Appearance: Colored clear liquid

Available colors: Red, Transparent, Gray, Black, White, Cherry

Odor: Odorless

Brookfield viscosity, Pa * s: 0.8-1

Tensile strength, N / mm2: 45

Elongation at break,%: 6-7

Shore hardness, D: 87-92

Shrinkage,%: <1

Price, rub. / Liter: about 7000, specify when ordering.

HARZ Labs Model is one of the hardest and hardest polymers. Accuracy at altitude

If the model is poorly washed or the polymer is underpolymerized, then whitish traces may remain.

Flashforge Hunter's flash options:

Layers, with: 3,5-4

The first layer, with: 15

Layer thickness, mm: 0.05

Comparison

The most convenient to print, from the presented - polymers Fun To Do. For products from Standard Blend, for example, it is very easy to remove support, and the parameters for the polymerization of these resins are already embedded in many printers, for example, in our test Flashforge Hunter. They are not as hard and hard as Harz Labs polymers, and do not stick to the film during printing.

The most accurate resins are UV Res. By hardness, to the touch, they are a cross between Harz Labs and Fun To Do. Very high detail. Minus - few flowers.

The hardest prints come from the Harz Labs Model - 87-92 D.

Available in several types and wide range of colors.

Comparison table:

General photos of products from all polymers:

From left to right: UV Res M111, M001, Harz Labs Model Red, Cherry, Black, Fun To Do Castable, Industrial, Standard Blend.

Used printers

Many stereolithographic 3D printers can print these materials, in fact, all that produce illumination in the required range of 405 nm.

We name just a few.

Working chamber, mm: 120 x 67.5 x 150

Printing technology: DLP

Layer thickness, µm, from: 25

Price, rub .: 273 900

Working chamber, mm: 120x68x200

Printing technology: LCD

Layer thickness, microns, from: 35

Price, rub .: 31 553

Working chamber, mm: 145 x 145 x 175 mm

Printing technology: SLA

Layer thickness, µm, from: 25

Price, rub .: 336 500

Working chamber, mm: 86.4 x 48.6 x 170

Printing technology: DLP

Layer thickness, µm, from: 10

Price, rub .: 260 000

findings

All the presented materials meet the requirements for polymers intended for prototyping - they are all quite strong, well polymerized, give high-quality prints.

The differences found during the tests are due to the specifics of the purpose of each individual material and are described above. Fun To Do Castable Blend, for example, can be used to print burnable casting models.

Having worked with these materials, we conclude that the available photopolymers are in no way inferior to the brand-name resins of manufacturers of 3D printers, and if the difference is not obvious, then why pay more?

It makes sense if you have an expensive branded printer, such as Form 2, and you want uninterrupted operation and simplicity at all costs.

But, if you are ready to experiment and save, affordable high-quality polymers are the best option.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks: