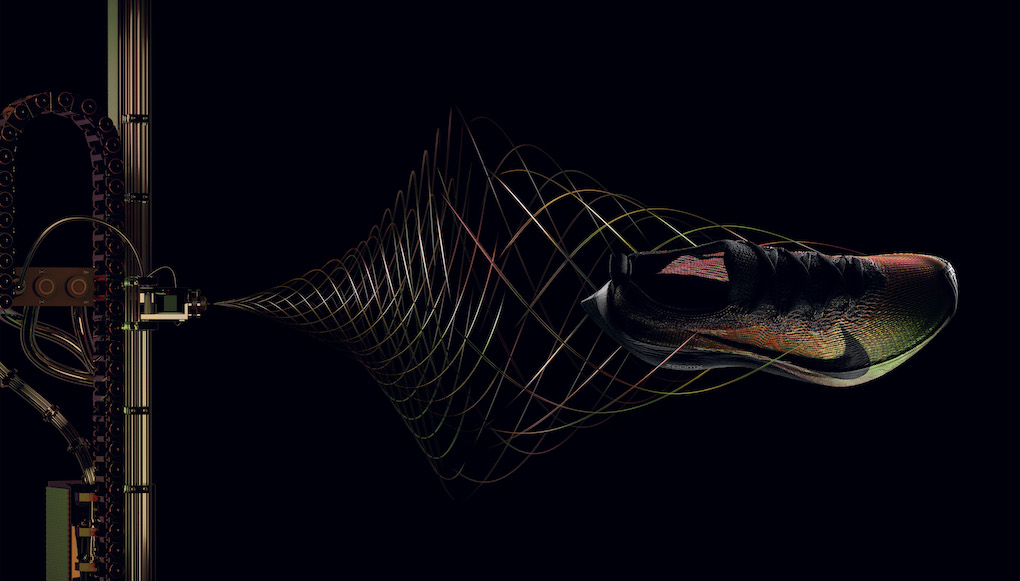

The other day, Nike released sneakers, created together with Eliud Kipchog - a man who almost broke the two-hour barrier in the marathon last year. This is the first shoe, the design of which was made by a computer, and she herself was printed on a 3D printer. The previous version, developed by Nike and Breaking2, allowed Kipchog to beat several world records. Organizers of the competition even called to equate it to doping. The new one uses a special ultra-light plastic and a generative design that will allow the runners to be pushed even further.

Computational (“generative”) design is the latest fashion trend in the production and 3D printing of clothing and footwear. If earlier architects, designers and fashion designers used their experience and intuition to create the look of their products, now computers can help them. They are beginning to be used not only as tools for drawing objects, as a substitute for pencil and paper. They become full participants in the process, partners who can make the approach to creating things more logical. One of the main advantages is that if algorithms are involved in the design of things, it will be much easier to create virtual models that are close to reality in order to check how changes in certain parameters show themselves.

This is the method developed by the new Vaporfly Elite Flyprint sneakers, the latest Nike pride. The company announced them on April 17th . You cannot buy them, they are intended only for elite runners, marathoners, and are developed with the participation of the best of them - Kenyan Eliud Kipchog.

Prior to that, Kiphoge was famous for his 2016 Olympic gold medal in the marathon and the best results of all time on the marathon routes of Hamburg, London and Berlin. The previous Nike sneakers, Zoom Vaporfly Elite 4%, helped him with this. All these records were a test of shoes, which, according to Nike (who invested more than $ 30 million in their development), was supposed to speed up a person by 4% and allow him to run a marathon for the first time in less than 2 hours.

We have already written about this gigantic project in the article “ Epic story about the race to 1:59:59 ”. Few people believed that such a venture could be crowned with success. And they were right: Kiphoge failed. In May 2017, he ran a 2:00:25 marathon, setting an unofficial world record and surpassing the previous time by more than two minutes, but the barrier at 2 o'clock is still not broken.

Nike then said that this was not the end. No wonder that their scientists knocked out their tattoos with the numbers of 1:59:59, and in the Kentaian forests of Captagat they built a laboratory to test the endurance of the athletes.

From May 2017, almost nothing was heard about them, and now, a year after the unsuccessful attempt of the race, new news came out of the laboratory: they developed the Vaporfly Elite FlyPrint. If the previous shoe allowed the athlete to run 4% faster, then this not only accelerates it, but also makes the run comfortable.

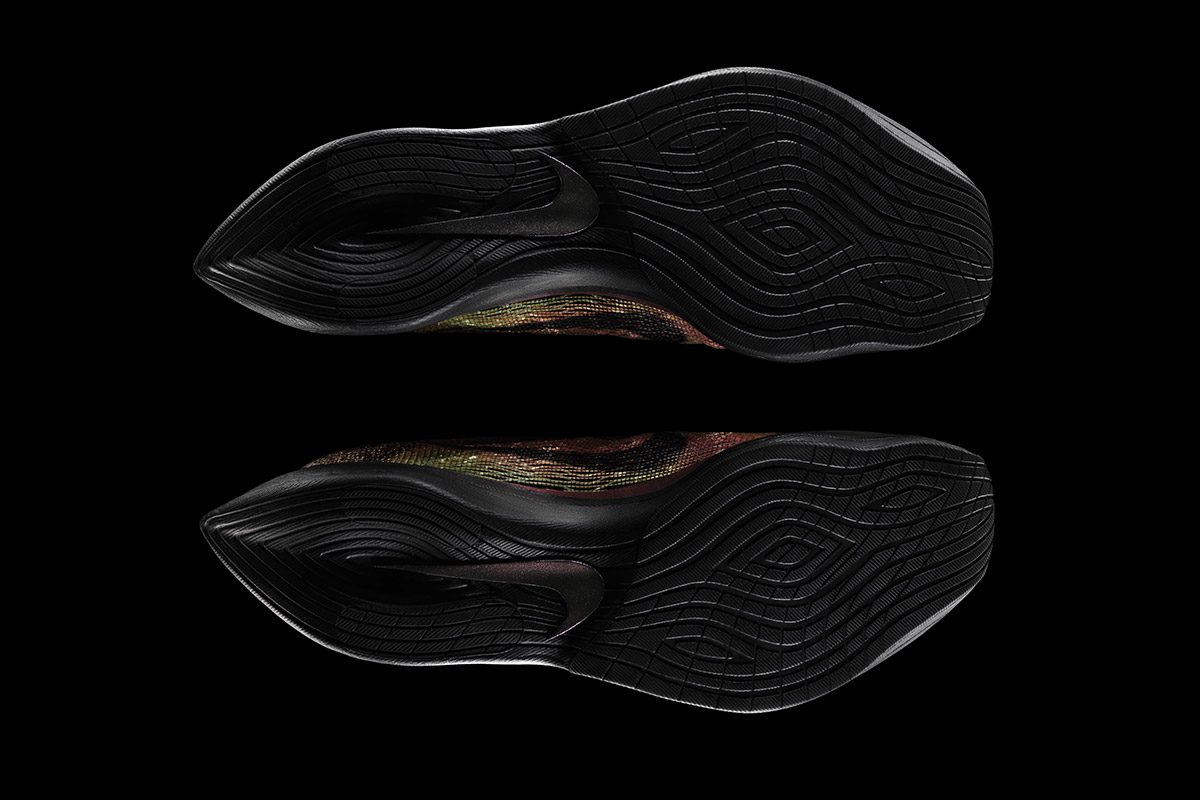

When creating shoes, all Kiphoge requests were taken into account, and the final design of the sneaker elements made a computer using the specified parameters. In the previous shoe, the main chip was in ZoomX foam, durable and very light. The highlight of the new model is the top of the shoe (the "vamp" and everything except the sole and tongue) of FlyPrint. As the name implies, tsimes is that all this is printed “on the fly” to the needs of a specific athlete. To do this, use a special 3D-printer, also developed in Nike, and the patented composition of polymers.

The material is attached to the insole of ZoomX using a special strong and almost weightless glue. Externally, the shoes look like ordinary sneakers, only a little more “transparent” and fragile in appearance. The material is durable, but plastic, like a fabric, and very thin, a few millimeters. Fans of massive, "male" sneakers FlyPrint are unlikely to be appreciated.

The tongue, the back and other outer parts of the shoe are made of FlyKnit polyester fabric, and they do not require glue or stitching to connect with FlyPrint plastic, which saves another fraction of a gram. The process of combining materials, according to the developers, most of all resembles spraying paint layers on furniture or a car.

Computers have helped with product development almost since their invention. It is difficult to imagine an industrial designer or architect who does not use any CAD system. But computational design is an evolution of this concept, which began to gain popularity literally in recent years, along with the development of neural networks and AI. Trained systems, trained on hundreds of thousands of examples, for the most part achieve a better result than people do if they are asked to optimize specific parameters. Nike “feeds” its model with the physical conditions in which it is necessary to perform sneakers, and indicates which indicators are in priority (minimum weight, sufficient endurance in specific areas, etc.).

For a person, building the best structure would be an overly complex and time consuming task. Especially if you are supposed to do each pair of sneakers under your runner. The machine also copes with all the calculations and design development in a few minutes.

The already released version of Vaporfly Elite FlyPrint used data from the Kenya laboratory in Kaptagata: the forces with which Eliud Kipchog's legs act on the material during the run. These data, together with information about the properties of Nike's proprietary polymer, made it possible to optimize shoes at each specific point. The top layer of sneakers is made extremely thin, but with the condition that it must withstand the marathon at such maximum loads.

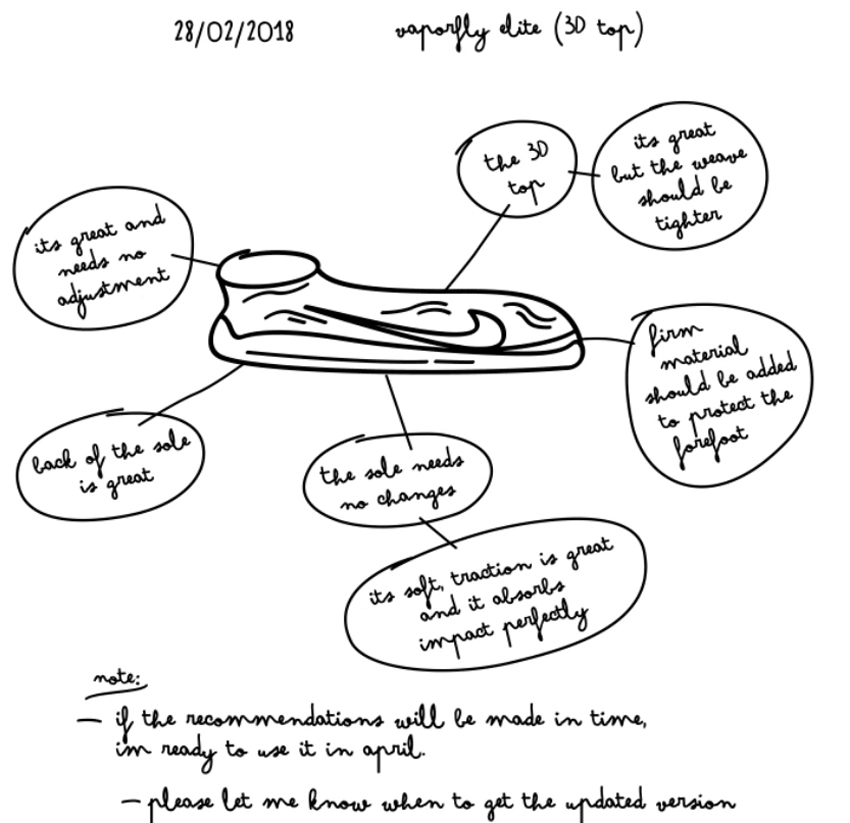

Eliuda comments on sneakers

Eliuda comments on sneakersAnd when Kiphoge complained about some inconvenience or said that he would like to get a little more support from the front of the sock, the team could enter this parameter into the system and within one day release a new top for the athlete with the specified changes. Previously, such a process, from creating a design to producing a finished batch, took up to 9 months. The development team says that now they can also easily adapt shoes to any foot size, observing the correct ratios of all materials.

As a result, Kiphoge and Nike had very lightweight shoes. Only the transition to the new polymer FlyPrint immediately reduced the weight of sneakers by 12 grams. During the marathon in Berlin, one of the big problems Eliud had with previous Zoom Vaporfly was moisture retention in sneakers during the rain. The sweat did not have time to evaporate at a high humidity in the atmosphere, and the athlete's legs began to mate worse with the inside of the shoe. In addition, sneakers gained weight. With the material FlyPrint this will not happen. The top here is so porous that it is almost transparent. Drainage problem resolved. And Kiphoga himself, in his words, especially likes the “feeling of flying” from all that air that sneaks into running shoes during the run.

FlyPrint Prototypes

FlyPrint PrototypesGenerative design in combination with 3D-printers right now put upside down how shoes are made. Adidas and Carbon focused on the insoles and soles when releasing printed shoes for basketball and the streets, while Nike makes sneakers for elite runners. Products made in this way can be changed at least every day, adjusting to a specific type of leg or to the requirements of fashion. A software designer becomes a manufacturer. He does not need a large factory and dozens of employees to implement his idea. And with the help of a computer, the final product is obtained even of higher quality. It reminds how Levi's started using a laser to make jeans . Instead of a team of workers using sandblasting, sprays of permanganate and other chemicals to create the right patterns on the surface of the fabric, this is now done by one “photoshoper” showing the laser where to shoot. Other people need only to bring the workpiece.

Eliud Kiphoge and Nike runners will perform for the first time in their new Vaporfly Elite FlyPrint at the London marathon on April 22. On the same weekend, several thousand pairs of shoes will be available for purchase in London through the Nike app. It is assumed that their price will start at $ 600, but there are concerns that most of the sneakers will grab eBay dealers.

PS Clothes and shoes are much more profitable to take in the United States. On Nike, adidas and New Balance, prices there are often a half to two times lower, not to mention more variety. And we can deliver the purchase to Russia, Pochtoy.com. From $ 8.99 per pound. Register with the code Geektimes to get to the account $ 7 to start.