What is sclerometry and tribometers? And how it saves equipment in production

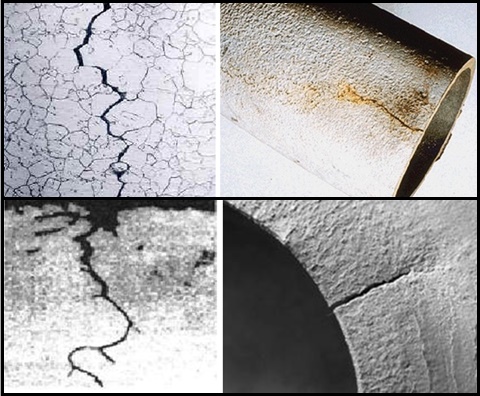

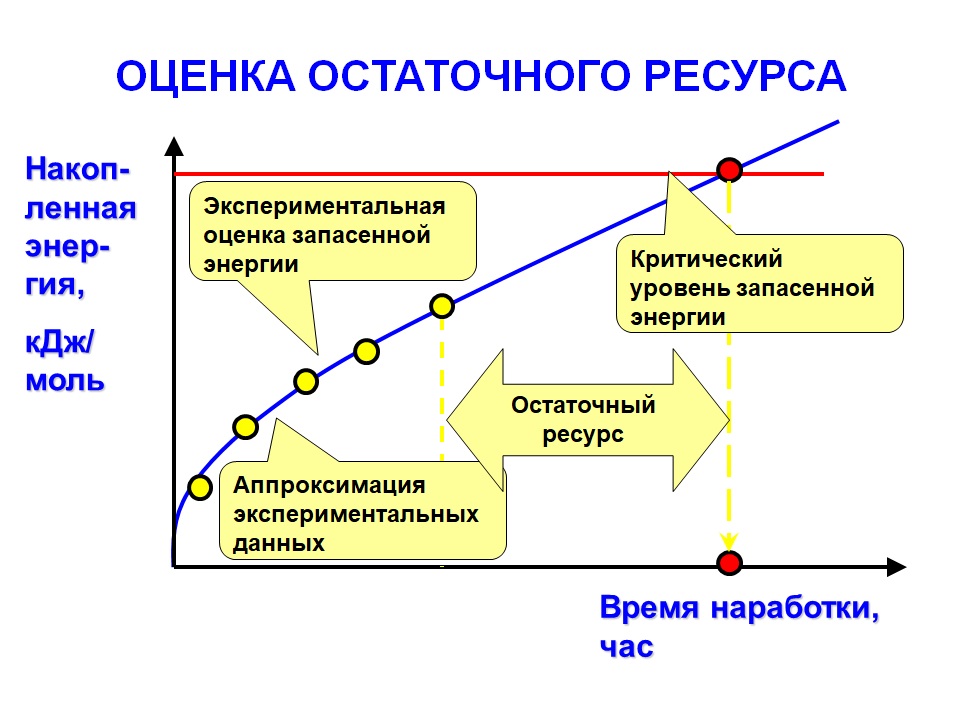

The idea to use the sclerometry method (microbore formation) to determine the specific energy of plastic deformation of the surface came almost immediately. Next - 15 years of experiments, during which it was found that fatigue failure is a complex multi-stage, multi-level process, which has a long latent (covert) embrittlement phase, accompanied by almost linear growth of the specific energy of plastic deformation of the material to some critical for each material, the critical level - energy activation damage.

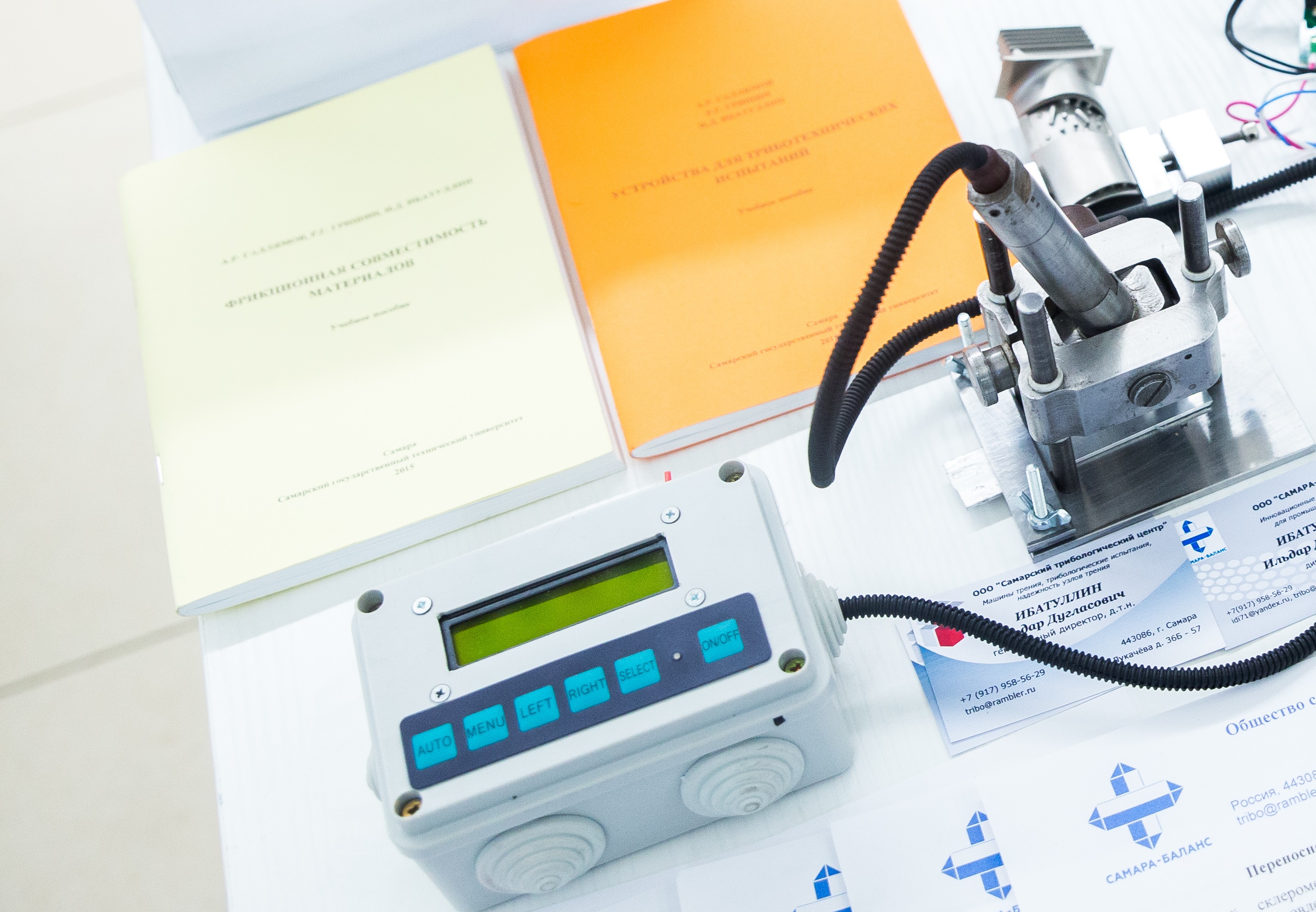

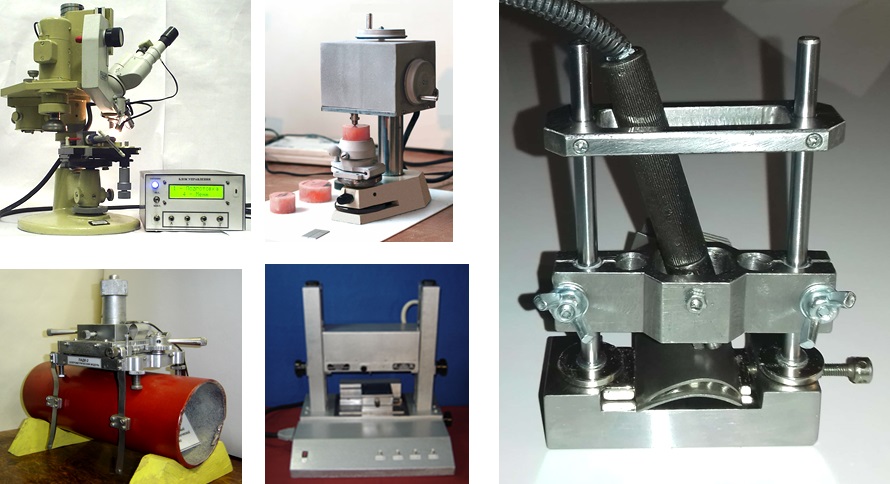

Sclerometer - a

device for determining the hardness of materials. Until the beginning of the last century, sclerometry was the only recognized method for assessing the hardness of materials, but in the early 1940s, the scratching method was almost completely supplanted by the currently well known methods of Rockwell, Vikkers, Brinell, etc., in which the hardness of materials was evaluated by indentation of indenters various forms.

Tribometer - a

projectile to determine the degree of friction of metals.Let us return to the description of the method of Samara colleagues. A similar pattern of embrittlement was observed during the hydrogenation of metals, the surface hardening with micro balls, cyclic shocks, and other destructive influences. This allowed us to create a methodology for predicting the damage associated with cracking materials based on the analysis of the kinetics of accumulated energy accumulation. Elementary physical carriers of excess energy are elastic distortions of the crystal lattice — defects that have atomic dimensions and therefore remain “invisible” to ordinary flaw detectors right up to the final stage of material damage — the formation of cracks.

The system includes a set of technical means of monitoring the actual state of materials and algorithms for making management decisions that ensure the careful and safe operation of products. It is implemented at all stages of the product life cycle - design, production and operation, includes active and passive control algorithms and allows solving direct (resource prediction) and inverse (optimization of technological modes and operating conditions) tasks.

It so happened that the historical roots and prospects for the development of the project of the Samara team (Samara Balance LLC) are inextricably linked with the northern capital of our country. The fundamental basis for predicting the destruction of materials — the thermal-fluctuation concept of strength — was laid by academician S.N. Zhurkov, who created a brilliant scientific school at the Leningrad Physical-Technical Institute of the Russian Academy of Sciences. Ioffe (now his work is continued by students in the laboratory of elementary acts of destruction).

The device makes on the part surface with a Vickers diamond indenter a tiny groove about 1 micron deep and assesses the degree of embrittlement.

“When the Nanotechnology Center of the Samara Region became interested in our innovative projects,” said the project founder, two more design companies Samara Tribological Center and Unidis LLC were created and received investments on the basis of the Zhiguli Valley.

Source: https://habr.com/ru/post/411601/

All Articles