Mask told how the company will reach the release of 5000 Tesla Model 3 per week by June

In an email to employees today, Tesla CEO Elon Musk explained that the reason for stopping Model 3 production at Fremont and Gigafactory 1 is preparing for an increase in production.

Musk explained that Tesla has now outlined to more than double its output - up to 6000 units per week for all production processes and suppliers, in order to reach 5000 units per week in June, taking into account the error.

This bold move seems to be related to the recent failure in the goals set regarding Model 3 and very much in the style of Mask. The previous level was set at 2500 units per week by the end of last year.

Tesla is now targeting 5,000 units a week at the end of the second quarter, and they seem to have adjusted their internal plans to achieve this goal.

In the letter, Mask also says that they focus on quality as the quantity increases, and now on the profits that Musk now expects in the third and fourth quarters of this year.

Electrek news resource received a copy of the email (translation):

Topic: Progress, Accuracy and Profit

From: Elon Musk

Appeal to all

Progress

First, congratulations to all! We completed the third full week of production of more than 2,000 Model 3 vehicles. The first week was 2020, the second 2070, and we just completed 2250 last week, along with 2,000 units of S / X models.

This is more than twice the pace of Tesla production last year and an amazing feat in the face of many problems! For a car company, it is extremely rare to increase production by more than 100% from year to year. In addition, at the same time there is a significant improvement in the quality and accuracy of the assembly, which is reflected in the positive feedback from the owners.

Starting today at Gigafactory and tomorrow at Fremont, we will stop the plants for three to five days to complete production line upgrades. This should lead us to producing Model 3 from 3000 to 4000 per week next month.

Another update at the end of May will be enough to increase production capacity to 6000 Model 3 cars per week by the end of June. Please note that all Tesla departments and our suppliers will have to demonstrate the implementation of the Model 3 ~ 6000 production plan per week by creating 850 sets of automotive parts within 24 hours no later than June 30th.

Any department or supplier of Tesla that cannot do this should have a very convincing explanation, as well as a plan to fix the problem and present it directly to me. If someone needs help achieving this, let me know as soon as possible.

The reason why the goal is 6000 rather than 5000 per week in June is that we cannot have a goal without correction for errors in thousands of parts and processes inside and out, reinforced by a complex global supply chain. Actual production will move as fast as the least successful and least well executed part of Tesla’s entire production system or supply chains.

Due to the fact that by the end of June the requirement for assembling subsystems of Model 3 will be 6 thousand, we will lay the foundation for achieving a stable rhythm of 6 thousand per week throughout the entire Model 3 system several months later.

As part of the transition to 6 thousand, the entire production of the model 3 in Fremont is transferred to the schedule 24/7. This means that we will add another shift to the general assembly, bodywork and painting. Please refer to those you know who you think meet the high standards of Tesla in terms of talent, drive and trust. For the Fremont and Gigafactory factory, Tesla will hire an additional about 400 employees per week for several weeks.

Accuracy

Most of the design tolerances Model 3 is already better than any other car in the world. Soon, all tolerances without exception will be better. This is not enough. We will continue to work until the accuracy of the construction of the Model 3 will not be 10 times better than any other machine in the world. I am not kidding.

Our car must be designed and built with such precision that if the owner measures the gaps in the panels and their measurements do not meet the specifications of the Model 3, it simply means that his measuring device is not accurate.

Some component suppliers will not want or be able to achieve this level of accuracy. I understand that some of these standards will be considered unreasonable. This is normal, there are many other car companies with much lower standards. They just can't work with Tesla.

Profit

A fair criticism of Tesla by third-party critics is that you are not a real company, unless you make a profit, which means that income exceeds expenses. This did not make sense to achieve the effect of large-scale production, but now we are at this line.

In the future, we will be much more stringent in terms of costs. I asked the Tesla financial team to comb all expenses around the world, no matter how small, and reduce everything that has no valid value.

All capital expenditures or other expenses in excess of a million dollars, or cumulative related expenses accumulated up to a million dollars over the next 12 months, must be put on hold until my personal approval. If you are a responsible manager, before we meet, make sure that you have a clear understanding of the supplier’s proposal, including every item, whether it be parts or services.

I was disappointed to know how many Tesla companies are intertwined. Often it looks like a Russian nesting doll from a contractor, subcontractor, subcontractor, etc., You have to work hard before you finally find out who does the actual work. This means that many middle managers add value, but do not do anything clearly useful. In addition, many contracts are essentially time and materials, rather than a fixed price and a specific time frame, which creates an incentive to present small groups as mountains, since they do not want to stop this cash flow.

There is a very wide range of contractors, from good to those that are worse than a drunken sloth. All contracting companies should consider the upcoming week as the last opportunity to demonstrate their superiority. Anyone who fails to attain Tesla's best practices will complete their contracts early on Monday.

By the way, here are some performance recommendations:

- Excessive meetings are a headache for large companies, and over time the situation only worsens. Please avoid large gatherings if you are not sure that they will benefit everyone, and even in this case, do not prolong their duration.

- Also get rid of frequent meetings if you are not dealing with an extremely urgent matter. The frequency of meetings should decrease rapidly after an urgent issue is resolved.

- Leave the meeting or end the call as soon as it is obvious that you are not adding details. Do not rudely leave, rudely force someone to stay and waste their time.

- Do not use abbreviations or meaningless words for objects, software or processes in Tesla. In general, all that requires an explanation, prevents communication. We do not want people to memorize a whole dictionary to work in Tesla.

- Communication should take place along the shortest path necessary to perform the work, and not through the “chain of commands”. Any manager who tries in this way to interact with teams will soon find work elsewhere.

- The main source of problems is poor communication between departments. The way to solve this issue is the free exchange of information between all levels. If in order to do something between departments, the employee must speak with his manager, who will talk with his boss, who will talk with the vice president, who will talk with another vice president, who will talk with another manager, who will talk with the manager If you talk to someone who does the actual work, then it will be very stupid. It should be in the order of things that people talk directly and just do their job.

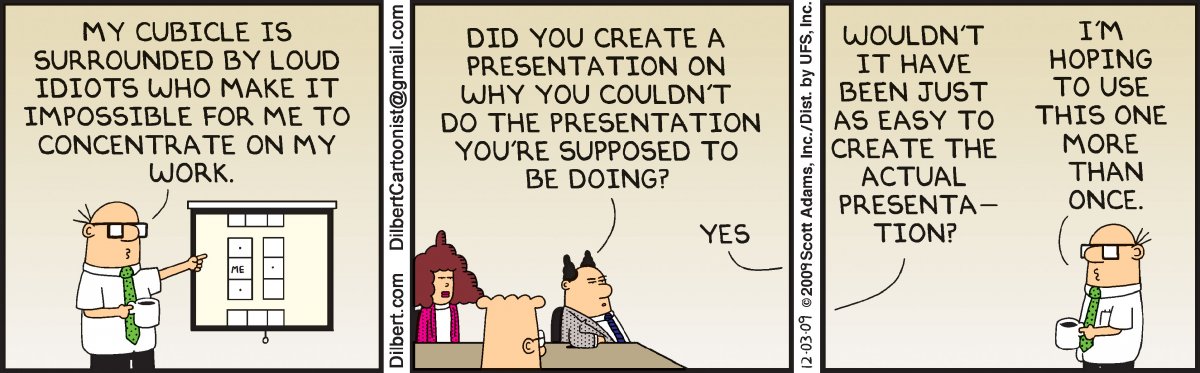

- In general, always use common sense. If you follow the "company rule" in a clearly absurd situation, as it happens in the Dilbert comics, then the rule should change.

The series of these comics refers to Ilon Musk in a letter.

Thank you for being such a damn cool team and doing feats every day. It is important. We work late to complete tasks on time.

Elon

PS: Mask also tweeted that over-production automation was his mistake and manual labor was underestimated.

Source: https://habr.com/ru/post/411599/

All Articles