One engineering company has developed a thermally conductive polymer composite that is superior to aluminum and other metals in its performance indicators in the manufacture of microelectronics products, LED elements and computer equipment.

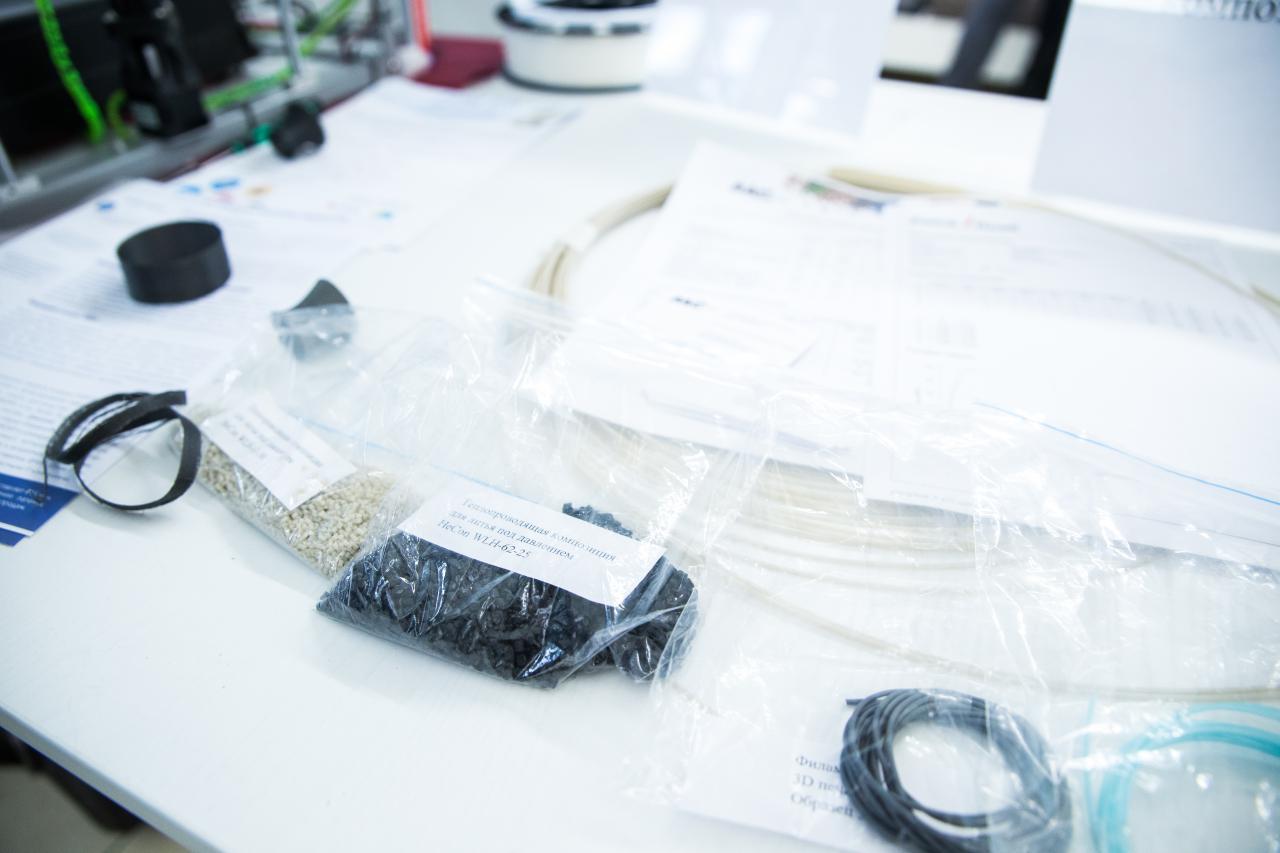

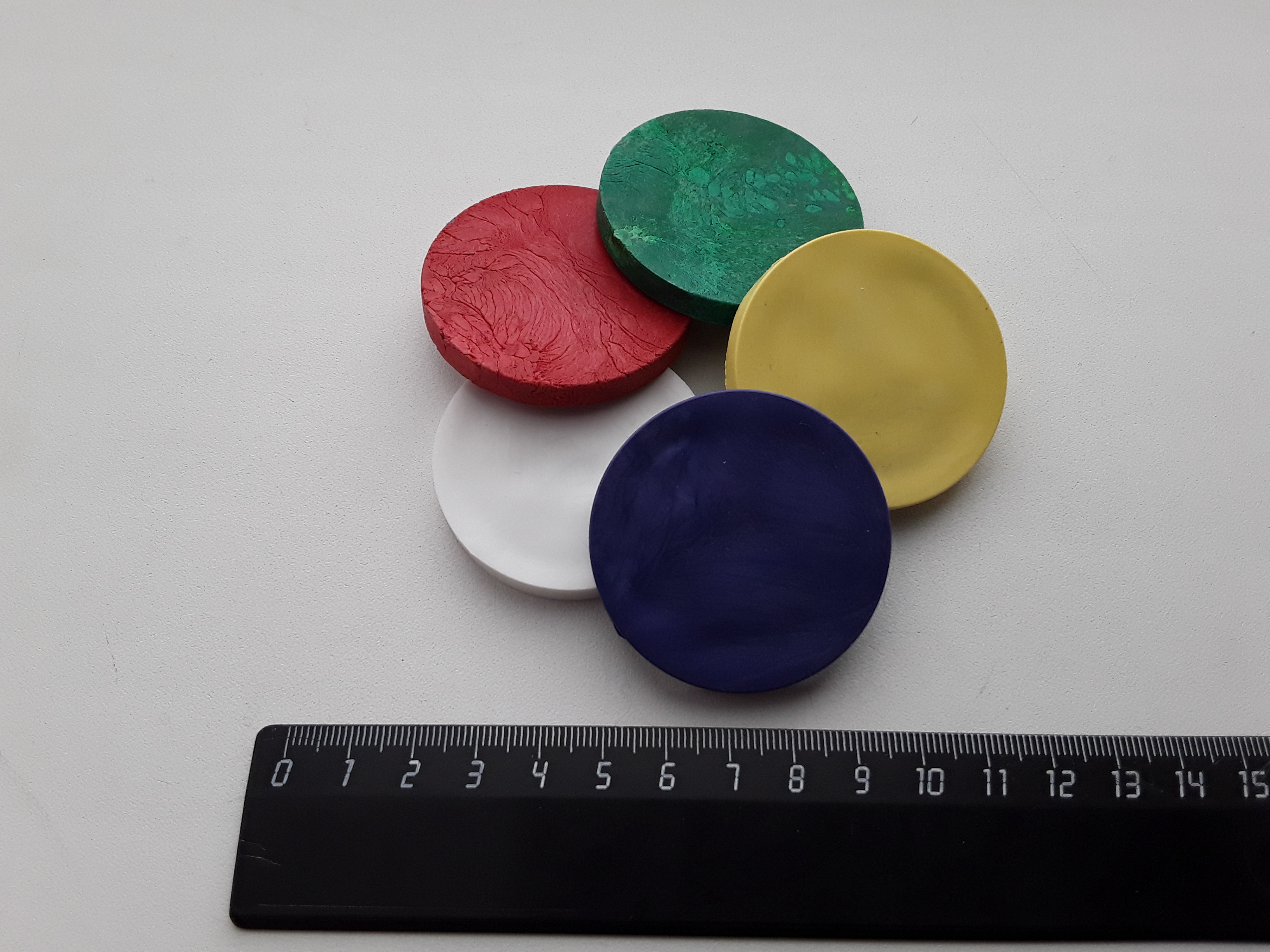

In the course of the project development, the developers experimented with materials on the existing laboratory base, regulating their thermophysical properties, electrical conductivity, mechanical characteristics, resistance to the action of the atmosphere and corrosive media, but eventually received compositions with better thermal conductivity. Now the company's polymer compounds have a thermal conductivity of 100 times or more than the thermal conductivity of conventional polymers. The project authors have found a production site where equipment rental and the production of pilot batches of new composite materials are possible.

“In the LED industry (LED) the“ technological limit ”has been reached, and to improve heat dissipation, additional complex structures must be created, since aluminum is not efficient and expensive. Consumers of the development are manufacturers of LED-lamps (the widest field of application and the most growing market), microelectronics and other industries where heat transfer is important, ”says project leader Andrei Kosenov.

Heat-conducting polymers are 38% cheaper than aluminum and other analogues by reducing the phasing of technological operations. Perspective composite materials solve the problems of heat transfer and are resistant to aggressive environment. According to the developers, no more than 10 companies in the world have developed such material.

“We can say that the century of polymers has come. Now we have set our sights on those applications that we did not decide on earlier, creating materials with new properties. We can predict how the supramolecular structure of the composite is formed, supramolecular interactions occur in the ingredient-ingredient system, the mechanisms of molecular reactions, the construction of new polymer structures using computer technology, the use of which facilitates and accelerates the development of materials. We have the opportunity to create modern materials necessary for use in the transport industry, microelectronics or advanced production. For example, a modern aircraft consists of composite materials by more than 50%, ”says the developer.

Composite business

In 2016, the developers won a venture fair, after which the investment fund invested 5 million rubles for 20% of the company. Production was suspended until the patent was granted. At the same time in the same year the sales turnover amounted to 37 thousand dollars. To enter the market, the company developed a ready-to-use product immediately. The first customer was the manufacturer of lighting equipment "Svetozar", which was replaced by material from AACPolymers (this is the name of the engineering company that made these polymers) Italian composite company LATI. Another potential consumer in the LED-lamp market is NEPES RUS.

“We started testing various types of products using 3D printing and working with target audiences that are in the industrial sector and had no idea how to use this material when heat transfer is important in aggressive environments and special conditions. We plan to get a patent, remove barriers that prevent its use and return to production and sales, since six plants expect composites from us, ”said the head of AACPolymers.

According to research firm Strategies Unlimited, the global market for thermally conductive polymer composites is $ 2.1 billion. By 2021, an increase to $ 11 billion is projected. The company plans to occupy 0.2% of the global market.